Abstract

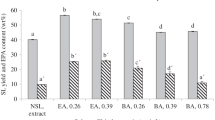

Eicosapentaenoic acid (EPA, 20∶5n-3) was obtained from the marine microalgaePhaeodactylum tricornutum by a three-step process: fatty acid extraction by direct saponification of biomass, polyunsaturated fatty acid (PUFA) concentration by formation of urea inclusion compounds, and EPA isolation by semipreparative high-performance liquid chromatography (HPLC). Alternatively, EPA was obtained by a similar two-step process without the PUFA concentration step by the urea method. Direct saponification of biomass was carried out with two solvents that contained KOH for lipid saponification. An increase in yield was obtained because the problems associated with emulsion formation were avoided by separating the biomass from the soap solution before adding hexane for extraction of insaponifiables. The most efficient solvent, ethanol (96%) at 60°C for 1 h, extracted 98.3% of EPA. PUFA were concentrated by the urea method with a urea/fatty acid ratio of 4∶1 at a crystallization temperature of 28°C and by using methanol and ethanol as urea solvents. An EPA concentration ratio of 1.73 (55.2∶31.9) and a recover yield of 78.6% were obtained with methanol as the urea solvent. This PUFA concentrate was used to obtain 93.4% pure EPA by semipreparative HPLC with a reverse-phase, C18, 10 mm i.d.×25-cm column and methanol/water (1% acetic acid), 80∶20 w/w, as the mobile phase. Eighty-five percent of EPA loaded was recovered, and 65.7% of EPA present inP. tricornutum biomass was recovered in highly pure form by this three-step downstream process. Alternatively, 93.6% pure EPA was isolated from the fatty acid extract (without the PUFA concentration step) with 100% EPA recovery yield. This two-step process increases the overall EPA yield to 98.3%, but it is only possible to obtain 20% as much EPA as that obtained by three-step downstream processing.

Similar content being viewed by others

References

Dyerberg, J., Linoleate-Derived Polyunsaturated Fatty Acids and Prevention of Atherosclerosis,Nutr. Rev. 44:125–134 (1986).

Simopoulos, A.P., Omega-3 Fatty Acids in Health and Disease and in Growth and Development,Am. J. Clin. Nutr. 54:438–463 (1991).

Ziboh, V.A., K.A. Cohen, C.N. Ellis, C. Miller, T.A. Hamilton, K. Kragbelle, C.R. Hydrick, and V.J. Voorhees, Effect of Dietary Supplementation of Fish Oil on Neutrophil and Epidermal Fatty Acids: Modulation of Clinical Course of Psoriatic Subjects,Arch. Dermatol. 122:1277–1282 (1986).

Braden, L.M., and K.K. Carroll, Dietary Polyunsaturated Fat in Relation to Mammary Carcinogenesis in Rats,Lipids 21:285–288 (1986).

Yongmanitchai, W., and O.P. Ward, ω-3 Fatty Acids. Alternative Sources of Production,Process Biochem, August, 117–125 (1989).

Kyle, D., Market Application for Microalgae,J. Am. Oil Chem. Soc. 66:648–653 (1989).

Molina Grima, E., F. García Camacho, J.A. Sánchez Pérez, J. Urda Cardona, F.G. Acién Fernández, and J.M. Fernández Sevilla, Outdoor Chemostat Culture ofPhaeodactylum tricornutum UTEX 640 in a Tubular Photobioreactor for the Production of Eicosapentaenoic Acid,Biotechnol. Appl. Biochem. 20:279–290 (1994).

Yongmanitchai, W., and O.P. Ward, Screening of Algae for Potential Alternative Sources of Eicosapentaenoic Acid,Phytochemistry 30:2963–2967 (1991).

Cohen, Z., and S. Cohen, Preparation of Eicosapentaenoic Acid (EPA) Concentrate fromPorphyridium cruentum, J. Am. Oil Chem. Soc. 68:16–19 (1991).

Cohen, Z., M. Reungjitchachawali, W. Siangdung, and M. Tanticharoen, Production and Partial Purification of γ-Linolenic Acid and Some Pigments fromSpirulina platensis, J. Appl. Phycol. 5:109–115 (1993).

O’Brien, D.J., and G.E. Senske, Recovery of Eicosapentaenoic Acid from Fungal Mycelia by Solvent Extraction,J. Am. Oil Chem. Soc. 71:947–950 (1994).

Akimoto, K., Y. Shinmen, H. Yamada, and S. Shimizu, Process for Production of Fatty Acids Having High Degree of Unsaturation, European Patent 0 355 972 A2 (1990).

Bligh, e.G., and W.J. Dyer, A Rapid Method of Total Lipid Extraction and Purification,Can. J. Biochem. Physiol. 37:911–917 (1959).

Hara, A., and N.S. Radin, Lipid Extraction of tissues with a Low-Toxicity Solvent,Anal. Biochem. 90:420–426 (1978).

Molina Grima, E., A. Robles Medina, A. Giménez Giménez, J.A. Sánchez Pérez, F. García Camacho, and J.L. García Sánchez, Comparison Between Extraction of Lipids and Fatty Acids from Microalgal Biomass,J. Am. Oil Chem. Soc. 71:955–959 (1994).

Robles Medina, A., A. Giménez Giménez, F. García Camacho, J.A. Sánchez Pérez, E. Molina Grima, and A. Contreras Gómez, Concentration and Purification of Stearidonic, Eicosapentaenoic, and Docosahexaenoic acids from Cod Liver Oil and the Marine Microalgaisochrysis galbana, Ibid. 72:575–583 (1995).

Robles Medina, A., A. Giménez Giménez, E. Molina Grima, and J.L. García Sánchez, Obtención de Concentrados de Acidos Grasos Poliinsaturados por el Método de los compuestos de Inclusión de Urea,Grasas y Aceites 42:174–182 (1995).

Kates, M., Techniques of Lipidology, 2nd edn., Elsevier Science Publishers B. V., Amsterdam, 1988, pp. 168–170.

Borowitzka, M.A., and B.E. Volcani, The Polymorphic DiatomPhaeodactylum tricornutum: Ultrastructure of Its Morphotipes,J. Phycol. 14:10–21 (1978).

Chrétiennot-Dinet, M.J.,Atlas du Phytoplancton Marin, Vol. 3, edited by Centre National de la Recherche Scientifique, Paris, 1990, pp. 85–86.

Ratnayake, W.M.N., B. Olsson, D. Matthews, and R.G. Ackman, Preparation of Omega-3 PUFA Concentrates from Fish Oilsvia Urea Complexation,Fat Sci. Technol. 10:381–386 (1988).

Belter, P.A., E.L. Cussler, and W.-S. Hu., Elution Chromatography, inBioseparation, Downstream Processing for Biotechnology, Wiley-Interscience Publications, John Wiley & Sons, Inc., New York, 1988, pp. 209–213.

Author information

Authors and Affiliations

About this article

Cite this article

Cartens, M., Grima, E.M., Medina, A.R. et al. Eicosapentaenoic acid (20∶5n-3) from the marine microalgaPhaeodactylum tricornutum . J Am Oil Chem Soc 73, 1025–1031 (1996). https://doi.org/10.1007/BF02523411

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02523411