Abstract

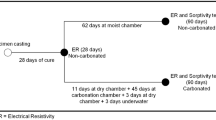

Experimental data are presented to illustrate the effects of cement type and curing upon the depth of carbonation and reinforcement corrosion in cover concrete after exposure for 18 months at 20°C and 60% relative humidity. Three curing periods (1, 3 and 28-days) and 17 cements, with various proportions of granulated blastfurnace slag or limestone, were used to make concretes, at 0.59 water/cement ratio, with 28 day strengths in the range 26 to 46 MPa. The depth of carbonation after 18 months was 64% greater than after 6 months and was affected more by cement type than by curing. The depth of carbonation increased when Portland cement clinker was replaced by 19% or more of limestone or granulated blastfurnace slag. The depth of carbonation after 18 months correlated better with the air permeability of cover concrete, initial weight loss (an indicator of moisture diffusion rate in cover concrete) or the cube strength 8 days after the end of curing than it did with 28-day cube strength.

The rate of reinforcement corrosion increased steeply when the carbonation front approached the reinforcing steel, and it was still increasing after the carbonation front had completely passed the reinforcement. For a given unneutralised remainder (i.e. cover depth minus the depth of carbonation), curing had little effect upon the rate of corrosion but higher rates were observed when the cement contained granulated blastfurnace slag. The results were broadly consistent with a simple engineering strategy in which the rate of carbonation was related to the air permeability of cover concrete, and the rate of any subsequent reinforcement corrosion was largely dependent upon moisture conditions, without any obvious influence of the cover depth or the permeability of the cover concrete. The results also suggested that estimation of the rate of reinforcement corrosion could be improved by taking account of the cement type and treating the unneutralised remainder as a variable.

Résumé

Les données expérimentales présentées dans cet article visent à illustrer les effets du type de ciment et de la cure sur la profondeur de carbonatation et la corrosion des armatures dans le béton d'enrobage après exposition pendant 18 mois à 20°C et à une humidité relative de 60%. Trois périodes de cure (1, 3 et 28 jours) et 17 ciments différents, avec des proportions variées de laitier granulé ou de pierre à chaux, ont été employés pour réaliser des bétons avec un rapport eau de gâchage/ciment de 0,59 et des résistances à 28 jours comprises entre 26 et 46 MPa. La profondeur de carbonatation après 18 mois s'est avérée être supérieure de 64% à celle obtenue après 6 mois, et dépendre davantage du type de ciment que de la cure. En effet, cette profondeur augmentait lorsque le clinker de ciment Portland était remplacé par au moins 19% de pierre à chaux ou de laitier granulé; et après 18 mois, elle présentait une meilleure corrélation avec la perméabilité à l'air du béton d'enrobage, la perte de poids initiale (indicateur de la vitesse de diffusion de l'humidité dans le béton d'enrobage) ou avec la résistance sur cube 8 jours après la fin de la cure qu'avec la résistance sur cube à 28 jours.

On a constaté que la vitesse de corrosion des armatures s'accroît rapidement lorsque le front de carbonatation se rapproche de l'armature, et s'accroît encore une fois que ce front a atteint et dépassé celle-ci. Pour la partie restante non carbonatée (c'est-à-dire épaisseur d'enrobage moins profondeur de carbonatation), la cure a peu d'effet sur la vitesse de corrosion, mais on observe des vitesses plus élevées lorsque le ciment contient des laitiers granulés. Ces résultats sont généralement cohérents avec la règle pratique selon laquelle le taux de carbonatation est lié à la perméabilité à l'air du béton d'enrobage, et la vitesse de corrosion des armatures qui en découle largement dépendante des conditions d'humidité, sans influence évidente de l'épaisseur d'enrobage ou de la perméabilité du béton d'enrobage. Les résultats suggèrent également que l'évaluation de la vitesse de corrosion des armatures peut être améliorée en tenant compte du type de ciment et en traitant la partie restante non carbonatée comme une variable.

Similar content being viewed by others

References

British Standards Institution. ‘Guide to life expectancy and durability of buildings and building elements’, Draft Standard 1988, DC 87/15323.

British Standards Institution. ‘Eurocode No. 2 Design of concrete structures, Part 1: General rules and rules for buildings’, DD ENV 1992-1-1, 1992.

British Standards Institution. ‘Concrete-performance, production, placing and compliance criteria’, ENV 206, 1992.

Kirkbride, T., ‘Concrete codes move into European context’,.Concrete, February 1989, 36–38.

Skalny, J.,et al., ‘Concrete durability: a multibillion dollar opportunity’, National Materials Advisory Board, National Academy Press, 1987, Report NMAB-437.

RILEM Technical Committee 60-CSC. ‘Corrosion of Steel in Concrete’, Chapman and Hall 1988, Ed. P Schiessl.

Macmillan, G., and Treadaway, K., ‘An exposure trial of concrete durability in Arabian Gulf conditions’, in Proc Corrosion of reinforcement in concrete, Wishaw UK, Elsevier 1990, Ed. C Pageet al., 109–118.

Rasheeduzzafar, S Al-Saadoun, Dakhil, F. and Al-Gahtani, A., ‘Effect of cement composition on corrosion of reinforcing steel in concrete’, in Proc Corrosion of reinforcement in concrete, Wishaw UK, Elsevier 1990, Ed. C Pageet al. 213–226.

Tuutti, K., ‘Corrosion of steel in concrete’, Swedish Cement and Concrete Institute, 1982, Report F04.

Parrott, L., ‘A review of carbonation in reinforced concrete’, BRE/BCA Report C/1, July 1987.

Andrade, C., Alonso, M. and Gonzalez, J., ‘An initial effort to use the corrosion rate measurements for estimating rebar durability’, Corrosion Rates of Steel in Concrete, ASTM STP 1065, 29–37.

Parrott, L., ‘Carbonation corrosion and standardization’, in Proc. Conference on Protection of Concrete, Dundee, September 1990, 1009–1023.

RILEM Technical Committee 116-PCD. ‘Performance Criteria for Concrete Durability’, Chapman and Hall, 1995.

Bilcik, J., ‘Permeability of concrete for calculating the life expectancy of reinforced concrete components’, in Proc Conference on Protection of Concrete, Ed. R Dhir and J Green, Dundee 1990, 681–688.

Parrott, L., ‘Design for avoiding damage due to carbonation-induced corrosion’, in CANMET Conference on Durability of Concrete, Nice, 1994, to be published.

Parrott, L., ‘Carbonation, moisture and empty pores’, Advances in Cement Research, 1992,4, (15), 111–118.

Parrott, L., ‘Rate of initial weight loss during exposure as an indicator of cover concrete performance’, British Cement Association Report C/9, March 1991.

Rostasy, F. and Bunte, D., ‘Evaluation of on-site conditions and durability of concrete panels exposed to weather’, in Proc IABSE Symposium on Durability of Structures, Lisbon, September 1989, 145–149.

Parrott, L., ‘Water absorption in cover concrete’, Mater. and Struct.,25 (1992), 284–292.

Parrott, L., Influence of cement type and curing on the drying and air permeability of cover concrete’,Magazine of Concrete Research,47, (171), 103–111.

Parrott, L., ‘A Study of carbonation-induced corrosion’. Magazine of Concrete Research,46, (166), (1994), 23–28.

Osborne, G., ‘Carbonation and permeability of blastfurnace slag cement concretes from field structures’, in Proc Third International Conf on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, ACI SP-114, Trondheim 1989, Vol 2, 1209–1237.

Schmidt, M., Harr, K. and Boeing, R., ‘Blended cement according to Env 197 and experiences in Germany’,Cement, Concrete Aggregates,15, (2), (1995), 156–164.

Parrott, L., ‘Effects of curing and cement type on the performance of cover concrete’, Concrete 2000, Ed R Dhir & M Jones, Dundee 1993, E & FN Spon, 705–715.

Burieke, F., and Hilsdorf, H., ‘Method to determine the durability potential of concrete’,Beton und Stahlbetonbau,88, (11), 306–308.

Dhir, R., Jones, R. and McCarthy, M., ‘Pulverised fuel ash concrete: carbonation-induced reinforcement corrosion rates’ in Proc. Institution of Civil Engineerings, August 1992, Vol. 94, 335–342.

Muller, K., ‘Possibility of predicting the service life of reinforced concrete structures’, in Proc. RILEM Symposium on Long-term observation of concrete structures, Budapest 1984, Vol 1, 9–20.

Ding, D.,et al. ‘Observations on reinforced concrete structures under long-term service’, ibid. in Proc. RILEM Symposium on Long-term observation of concrete structures, Budapest 1984, Vol 1, 49–57.

Kashino, N., ‘Investigation into the limit of initial corrosion occurrence in existing reinforced concrete structures’, in Proc. Durability of Building Materials and Components, Espoo, August 1984, Vol 3, 176–186.

Saeki, N., Takada, N., and Fujita, Y., ‘Influence of carbonation and sea water on corrosion of steel in concrete'in Trans. Jap. Concrete Institute, 1984, Vol 6, 155–162.

Parrott, L. and Killoh, D., ‘Carbonation in a 36 year old in-situ concrete’,Cement and Concrete Research,19 (4), (1989), 649–656.

Parrott, L., ‘Assessing carbonation in concrete structures’, in Proc 5th International Conference on Durability of Building Materials and Components, Brighton, November 1990, 275–286.

Author information

Authors and Affiliations

Additional information

Editorial note Dr. L. J. Parrott is employed by the British Cement Association wich is a RILEM Titular Member. He is working in several RILEM Technical Committees: 104-DCC on Damage Classification of Concrete structures and 116-PCD on Pemeability of Concrete as a criterion of its Durability as a full member, and 123-MME on Use of Microstructural Models and Expert systems for cementitious materials as a corresponding member.

Rights and permissions

About this article

Cite this article

Parrott, L.J. Some effects of cement and curing upon carbonation and reinforcement corrosion in concrete. Mat. Struct. 29, 164–173 (1996). https://doi.org/10.1007/BF02486162

Issue Date:

DOI: https://doi.org/10.1007/BF02486162