Abstract

The objectives of the research program were to investigate the effect of transverse reinforcement on the bond-slip characteristics of tension lap splices in high performance silica fume concrete, to study the validity of the upper limit of 70 MPa imposed by the ACI Building Code 318-95 on the concrete compressive strength for determination of development length, and to evaluate the reliability of the empirical equation of Orangun, Jirsa, and Breen in estimating the bond strength of tension lap splices embedded in high strength concrete and confined with transverse reinforcement.

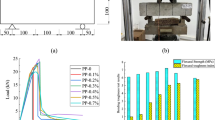

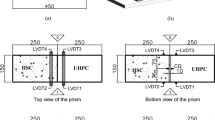

Twelve beam specimens were tested. Each beam specimen included two bars in tension, spliced at the center of the span. The beams were designed in way that bars would fail in bond, splitting the concrete conver in the splice region, before reaching the yield splice in a constant moment region. The variables used were the percentage replacement by weight of cement by silica fume and the amount of confinement over the splice region.

Test results indicated that silica fume decreased the bond strength and that specimens containing silica fume but without transverse reinforcement in the splice region had a brittle, sudden and noisy mode of failure. The use of transverse reinforcement in the splice region increased the bond strength and the ductibility of the mode of failure of the beam specimens. Minimum amount of transverse reinforcement was recommended.

Résumé

Les objectifs du programme de recherche consistent à examiner l'effet des armatures transversales sur les caractéristiques de glissement des longueurs de recouvrement en tension des armatures d'un BHP (béton de hautes performances) utilisant de la fumée de silice, afin d'étudier la validité de la limite supérieure de 70 MPa imposée par le ACI Building code 318-95 sur la résistance à la compression du béton pour la détermination de la longueur de scellement, et afin d'évaluer la fiabilité de l'équation empirique d'Orangun, Jirsa et Brean dans l'estimation de la force d'adhérence des longueurs de recouvrement en tension, encastrées dans un béton de hautes performances et confinées avec des armatures transversales.

Douze spécimens de poutre ont été testées. Chaque spécimen de poutre contenait deux armatures en tension, dont le recouvrement se situe au centre de la portée. Les poutres ont été étudiées de façon à présenter une rupture en adhérence, fissurant l'enrobage du béton dans la région de recouvrement, avant d'atteindre la limite de résistance. Les poutres ont été chargées avec un moment positif, le recouvrement étant situé dans une région de moment constant. Les variables utilisées étaient le pourcentage en poids de ciment remplacé par de la fumée de silice et la zone de confinement dans la région de recouvrement.

Les résultats des essais indiquent que la fumée de silice diminue la force d'adhérence, et que les spécimens contenant de la fumée de silice sans armature transversale dans la région de recouvrement présentent une rupture fragile, soudaine et sonore. L'usage des armatures transversales dans la région de recouvrement a augmenté la force d'adhérence et la ductilité du type de rupture des spécimens de poutres. Une quantité minimale d'armatures transversales est conseillée.

Similar content being viewed by others

Abbreviations

- atr :

-

area of transverse reinforcement crossing the potential plane of splitting adjacent to a single anchored reinforcement

- Atr :

-

total cross-sectional area of all transverse reinforcement which is within spacing s and which crosses the potential plane of splitting

- c:

-

the smaller of cb or cs

- cb :

-

clear (bottom or side) cover to main reinforcement

- cs :

-

half clear spacing between bars or splicer or half available concrete width per bar or splice resisting splitting in the failure plane

- db :

-

diameter of reinforcing bar

- f'c :

-

compressive strength of concrete

- fs :

-

stress in reinforcing steel

- fyt :

-

yield strength of transverse reinforcement

- ktr :

-

an index of the transverse reinforcement provided along the anchored bar

- ls :

-

length of lap splice

- ld :

-

development length

- ldb :

-

basic development length

- n:

-

number of bars being spliced along the plane of splitting

- s:

-

center-to-center spacing of transverse reinforcement within ls

- α:

-

reinforcement location factor

- β:

-

coating factor

- γ:

-

reinforcement size factor

- λ:

-

lightweight aggregate concrete factor

References

Hwang, S., Lee, Y. and Lee, C., ‘Effect of silica fume on the splice strength of deformed bars of high-performance concrete’,ACI Structural Journal 91 (3) (1994) 294–302.

Hamad, B. and Itani, M., ‘Bond strength of reinforcement in high performance concrete: role of silica fume, casting position, and superplasticizer dosage’,ACI Materials Journal 95 (5) (1998) 499–511.

ACI Committee 318, ‘Building Code Requirements for Reinforced Concrete and Commentary (ACI-318-95/ACI-318R-95)’, American Concrete Institute, Detroit, MI, 1995.

Azizinamini, A., Stark, M., Roller, J. J. and Ghosh, S. K., ‘Bond performance of reinforcing bars embedded in high strength concrete’,ACI Structural Journal 90 (5) (1993) 554–561.

Orangun, O. C., Jirsa, J. O. and Breen, J. E., ‘The strength of anchored bars: A reevaluation of test data on development length and splices’ACI Journal (March 1977) 114–122.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hamad, B.S., Machaka, M.F. Effect of transverse reinforcement on bond strength of reinforcing bars in silica fume concrete. Mat. Struct. 32, 468–476 (1999). https://doi.org/10.1007/BF02482719

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02482719