Abstract

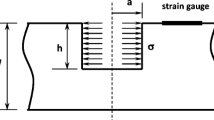

This paper presents a modified hole-drilling technique for measuring residual stresses in sheet and thin-plate materials. The primary advantage of the modification is that it eliminates the necessity for calibration of each experimental hole-gage assembly. The relaxation coefficients are calculated from theory, and the strain components which are extraneous to the true relaxation strains are determined and separated from the measured relaxation strains.

Experiments were conducted on 0.050-in. (1.27-mm) and 0.125-in. (3.175-mm)-thickness aluminum-alloy specimens. Sources of extraneous strain components are analyzed and values for these strain components resulting from machining residual stresses and localized plastic yielding are determined. Finally, the recommended range of the nondimensional ratio of hole diameter to distance between hole center and strain-gage center is determined by the maximum permissible error in residual-stress estimates. The modified technique appears to be accurate within ±5 percent or better and is, therefore, comparable in precision with the X-ray technique.

Similar content being viewed by others

Abbreviations

- c d ,(c d ′) :

-

drilling clearance, in. (mm)

- d :

-

hole size, in. (mm)

- E :

-

modulus of elasticity, psi (MPa)

- GL :

-

gage length of strain gage, in. (mm)

- K r ,K θ :

-

relaxation coefficients in the radial and tangential directions, respectively, dimensionless

- r :

-

distance from the hole center to straingage center, in. (mm)

- δ:

-

sign operator =±1

- ∈ :

-

strain, in./in. (m/m)

- ∈ R :

-

relaxation strain

- ∈ Rr , ∈ Rθ :

-

relaxation strains in the radial and tangential directions, respectively

- ∈ T :

-

total strain relaxation, as measured

- ∈ m :

-

relaxation strain due to machining stresses

- ∈ p :

-

relaxation strain due to localized plastic yielding

- ∈ r °, ∈ θ ° :

-

radial and tangential strains in the vicinity of the drilled hole

- ∈ r °, ∈ θ ° :

-

radial and tangential strains in a uniform strain field

- θ :

-

angle between the direction of measurement and the stress direction, deg

- φ i :

-

indicates hole diameter after theith drilling sequence

- λ:

-

parameter defined byd/r, dimensionless

- ν:

-

Poisson's ratio of the material

- σ:

-

stress, psi (MPa)

- σ x :

-

uniform stress

- ∈ x ' :

-

the calculated stress

- σ r , σ θ , ∈ r θ :

-

radial, tangential and shear-stress components

- σ y :

-

the yield stress of the material

References

Mather, J., “Determination of Residual Stresses by Measuring the Deformation Around Drilled Holes,”Trans. ASME 56,249–254 (1934).

Soete, W. andVancrombrugge, R., “An Industrial Method for the Determination of Residual Stresses,”Proc. SESA 8 (1),17–26 (1950).

Riparbelli, C., “A Method for the Determination of Initial Stresses,”Proc. SESA 8 (1),173–196 (1950).

Kelsey, R. A., “Measuring Non-uniform Residual Stresses By the Hole-drilling Method,”Proc. SESA 14 (1),181–194 (1956).

Rendler, N. J. andVigness, I., “Hole-drilling Strain-Gage Method of Measuring Residual Stresses,”Experimental Mechanics,6 (12),577–586 (Dec. 1966).

Cordiano, H. V. andSalerno, V. L., “Study of Residual Stresses in Linearly Varying Biaxial-stress Fields,”Experimental Mechanics,9 (1),17–24 (Jan. 1969).

Lake, B. R., Appl., F. J., andBert, C. W., “An Investigation of the Hole-drilling Technique for Measuring Planar Residual Stress in Rectangularly Orthotropic Materials,”Experimental Mechanics,10 (6),233–239 (June 1970).

Tebedge, N., Alpsten, G. A., and Tall, L., “Measurement of Residual Stresses—A Study of Methods,” Fritz Eng. Lab. Rep. No. 337.8, Lehigh Univ. (Feb. 1971).

Timoshenko, S. P. and Goodier, J. N., “Theory of Elasticity,” 3rd Ed., McGraw-Hill 91 (1970).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Nawwar, A.M., McLachlan, K. & Shewchuk, J. A modified hole-drilling technique for determining residual stresses in thin plates. Experimental Mechanics 16, 226–232 (1976). https://doi.org/10.1007/BF02329273

Issue Date:

DOI: https://doi.org/10.1007/BF02329273