Abstract

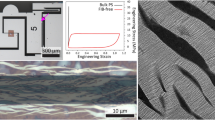

Microsample tensile testing has been established as a means of evaluating the room temperature mechanical properties of specimens with gage sections that are tens to hundreds of microns thick and several hundred microns wide. The desire to characterize the mechanical response of materials at elevated temperatures has motivated the development of high-temperature microsample testing that is reported here. The design of specially insulated grips allows the microsamples to be resistively heated using approximately 2 V DC and currents ranging between 2 to 6 A. An optical pyrometer with nominal spot size of 290 μm and 12 μm diameter type K thermocouples was employed to measure and verify the temperature of the microsamples. The ability of the pyrometer to accurately measure temperature on microsamples of different thicknesses and with slightly different emissivities was established over a temperature range from 400°C to 1100°C. The temperature gradient along the length and thickness of the microsample was measured, and the temperature difference measured in the gage section used for strain measurements was found to be less than 6.5°C. Examples of elevated temperature tensile and creep tests are presented.

Similar content being viewed by others

References

Sharpe, W.N., Jr., “Applications of the Interferometric Strain/Displacement Gage,”Opt. Eng.,21,483–488 (1982).

Sharpe, W.N., Jr., “An Interferometric Strain/Displacement Measurement System,” Report No. 101638, Mechanics and Materials Branch, NASA Langley Research Center (1989).

Sharpe, W.N., Jr. andFowler, R.O., “A Novel Miniature Tension Test Machine,”Small Specimen Test Techniques Applied to Nuclear Reactor Vessel Thermal Annealing and Plant Life Extension, ed. W.R. Corwin, F.M. Haggag, andW.L. Server, American Society for Testing and Materials, Philadelphia (1993).

Sharpe, W.N., Jr., Yuan, B., Vaidyanathan, R., andEdwards, R.L., “New Test Structures and Techniques for Measurement of Mechanical Properties of MEMS Materials,”SPIE 2880,78 (1996).

Sharpe, W.N., Jr., Yuan, B., Edwards, R.L., and Vaidaynathan, R., “Measurements of Young's Modulus, Poisson's Ratio, and Tensile Strength of Polysilicon,” 10th IEE International Workshop on MEMS, Nagoya, Japan, 424 (1997).

LaVan, D. andSharpe, W.N., Jr., “Mechanical Testing of Tensile Microspecimens Taken from Weld Beads,”Report to the Fatigue and Fracture Branch, Canderock Division, Naval Surface Warfare Center, Bethesda, MD (1996).

Yuan, B. andSharpe, W.N., Jr., “Fatigue Testing of Microspecimens from a Weldment,”J. Testing Eval.,25,485–490 (1996).

Sharpe, W.N., Jr., LaVan, D.A., and McAleavey, A., “Mechanical Testing of Thicker MEMS Materials,” Micro-electro-mechanical Systems, ASME,DSC-Vol. 62/HTD-Vol. 345,93–97 (1997).

Sharpe, W.N., Jr. andMcAleavey, A., “Tensile Properties of LIGA Nickel,” Symposium on Materials and Device Characterization in Micromachining,SPIE 3512,Santa Clara, CA,130–137 (1998).

McAleavey, A., Coles, G., Edwards, R.L., and Sharpe, W.N., Jr., “Mechanical Properties of SU-8, Microelectromechanical Devices,” Materials Research Society Symposium Proceedings, Boston, MA (1998).

Zupan, M., LaVan, D., and Hemker, K.J., “Tensile and Compression Testing of Single Crystal Gamma Ti-55.5 Al,” Materials Research Society Symposium Proceedings, Boston, MA (1996).

Zupan, M. andHemker, K.J., “Tension and Compression Testing of Single Crystalline Gamma TiAl,”Metallurg. Mat. Trans. A,29A,65–71 (1998).

Legros, M., Hemker, K.J., LaVan, D.A., Sharpe, W.N., Jr., Rittner, M.N., and Weertman, J.R., “Micro-tensile Testing of Nanocrystalline Al/Zr Alloys,” Materials Research Society Symposium Proceedings, Boston, MA, 273–278 (1996).

Agnew, S.R., Elliot, B.R., Youngdahl, C.J., Hemker, K.J., andWeertman, J.R., “Microstructure and Mechanical Behaviour of Nanocrystalline Metals,”Mat. Sci. Eng. A,285,391–396 (2000).

Legros, M., Elliot, B.R., Rittner, M.N., Weertman, J.R., andHemker, K.J., “Microsample Tensile Testing of Nanocrystalline Metals,”Phil. Mag. A,80,1017–1026 (2000).

Coe, D.J., “The Application of Microsample Testing to an Investigation of Electron Irradiation Effects on Type 316 Stainless Steel and Fe−Cu−Mn,” Master's thesis, Johns Hopkins University (1999).

Burns, G.W., Scroger, M.G., Strouse, G.F., Croarkin, M.C., and Guthrie, W.F., “National Institute of Standards and Technology Monograph on Thermocouples,” National Institute of Standards and Technology Monograph No. 175, 630 (1993).

Zupan, M., “Microsample Characterization of the Tensile and Compressive Mechanical Properties of Single Crystalline Gamma-TiAl,” PhD thesis, Johns Hopkins University (2000).

Boehlert, C.J., Zupan, M., Dimiduk, D.M., andHemker, K.J., “Microsample Creep Testing of Fully-lamellar TiAl Alloys,”Gamma Titanium Aluminides 1999, ed. Y.M. Kim, D.M. Dimiduk andM.H. Loretto, TMS, Warrendale, PA, 669–677 (1999).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zupan, M., Hayden, M.J., Boehlert, C.J. et al. Development of high-temperature microsample testing. Experimental Mechanics 41, 242–247 (2001). https://doi.org/10.1007/BF02323140

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02323140