Abstract

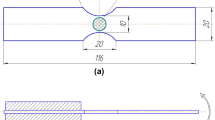

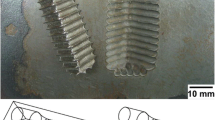

An experimental technique to monitor the length and the opening level of a short fatigue crack is presented. It is based on the progressive decrease with crack length of the response of miniature strain gages installed on the surface near the crack plane. A first gage installed close to the crack plane can monitor cracks from 10 μm in depth to half a millimeter where the response saturates. Other gages at larger distances from the crack plane are less sensitive but can monitor longer cracks. The response is measured so that it is independent of strain-gage calibration, Young's modulus and Poisson's ratio. The paper first presents the basic principles and possibilities of the technique as well as a finite-element analysis performed on automatic welded joints with straight-fronted cracks for which the technique has been developed. The results give a correlation between gage response, crack length and gage location and the conditions of replacement of a gage reaching saturation. The practical exploitation of the technique has required further work to derive a continuous calibration of the gage response that includes corrections to account for the gage finite dimensions and the crack-plane inclination. This calibration is shown to give crack lengths that compare well with fractographic marks and typical results that have been obtained on short crack growth at the weld toe are presented. In particular, the resolution of the technique is put into evidence with results on the initial growth of a 0.1 mm nonpropagating crack. The paper finally points out the distinctive features that appear in current works to adapt the technique to the growth of semi-elliptical cracks of low and high aspect ratio.

Similar content being viewed by others

References

Phillips, E.P. andNewman, J.C., Jr, “Impact of Small-Crack Effects on Design-life Calculations,”Experimental Mechanics,29 (2),221–225 (1989).

Verreman, Y., Dickson, J.I. and Bailon, J.P., “Generalization of the Kitagawa Diagram to V-Notched Members,” Advances in Fatigue Science and Technology, ed. C. Moura Branco and L. Guerra Rosa, Kluwer Academic Publishers, 785–798 (1989).

De Los Rios, E.R., “Experimental Techniques to Observe and Monitor Short Fatigue Cracks,” Advances in Fatigue Science and Technology, ed. C. Moura Branco and L. Guerra Rosa, Kluwer Academic Publishers, 265–281 (1989).

Brown, C.W. and Smith, G.C., “A Two Stage Plastic Replication Technique for Monitoring Fatigue Crack Initiation and Early Fatigue Crack Growth,” Advances in Crack Length Measurement, ed. C.J. Beevers, Engineering Materials Advisory Services, 41–51 (1982).

Verreman, Y., Bailon, J.P. and Masounave, J., “Fatigue Short Crack Propagation and Plasticity-Induced Crack Closure at the Toe of a Fillet Welded Joint,” The Behaviour of Short Fatigue Cracks, ed. K.J. Miller and E.R. de Los Rios, Mechanical Engineering Publications, London, EGF Pub. 1, 387–404 (1986).

Verreman, Y., Bailon, J.P. and Masounave, J., “Closure and Propagation Behavior of Short Fatigue Cracks at Different R-Ratios,” Fatigue 87, ed. R.O. Ritchie and E.A. Starke, 371–380 (1987).

Mattos, R.J. and Lawrence, F.V., “Estimation of the Fatigue Crack Initiation Life in Welds Using Low Cycle Fatigue Concepts,” Soc. of Auto. Engl., SP/24 (1989).

Usami, S., Kimoto, H. andKusumoto, S., “Cyclic Strain and Fatigue Strength at the Toes of Heavy Welded Joint,”Trans. Jap. Weld. Soc. 9,118–127 (1978).

Verreman, Y., Bailon, J.P. andMasounave, J., “Fatigue Life Prediction of Welded Joints. A Re-Assessment,”Fatigue Fract. Eng. Mat. Struct.,10 (1),17–36 (1987).

El Haddad, M.H., Smith, K.N. and Topper, T.H., “A Strain-based Intensity Factor Solution for Short Fatigue Cracks Initiating from Notches,” ASTM STP 677, 274–289 (1979).

Nie, B., Verreman, Y. and Audoin, M., “Influence of Welding Residual Stresses on the Closure and Propagation Behavior of Fatigue Cracks at a Fillet Weld Toe,” Proc. 2nd Int. Conf. on Residual Stresses (ICRS2), ed. G. Beck, S. Denis and A. Simon, Elsevier Applied Science, 965–970 (1989).

Otegui, J.L., “Fatigue Crack Initiation and Coalescence in Welded Joints in Steel,”PhD Thesis, Mech. Eng., Univ. of Waterloo, Canada (1988).

Verreman, Y. andNie, B., “Short Crack Growth and Coalescence along the Toe of a Manual Fillet Weld,”Fatigue Fract. Eng. Mat. Struct.,14 (2/3),337–349 (1991).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Verreman, Y. Monitoring short fatigue cracks with miniature strain gages. Experimental Mechanics 34, 208–216 (1994). https://doi.org/10.1007/BF02319757

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02319757