Abstract

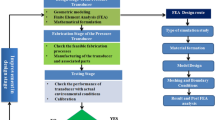

This paper describes the application of the traditional four-point bending technique to conduct strain gage performance tests at moderate temperatures. The tests measure the apparent strain, linearity, drift, creep and hysteresis behavior to ascertain the reliability of strain gages to be used in the testing of experimental cylindrical vessels subjected to thermal loading. The four-point bending rig was designed to take advantage of the advances in personal computer datalogging and graphical processing software. The test rig is designed to provide a thermal barrier to minimize the heat losses and thermal isolation of the test beam while maintaining structural continuity. A low wattage and lightweight electric foil heater incorporating a precise temperature controller minimizes weight and enhances temperature stability. Gage performance data on five “candidate” strain gages at temperatures ranging from ambient to 215°C (419°F) are presented, and the evaluation procedure is outlined. The strain gage with the most acceptable performance was identified within the validity limits from ambient to a temperature of 215°C and from zero to a maximum strain of 1000 μ∈.

Similar content being viewed by others

References

Cheung, J.S.T., Tooth, A.S., Nadarajah, C., Ong, L.S. and Ng, H.W., “Horizontal Pressure Vessels on Fixed Saddle Supports under Thermal Expansion Loading—A Study on 3 Different Saddle Designs,” Proc. Int. Conf. Mech. Solids Mat. Eng., Singapore (June 1995).

Tooth, A.S., Cheung, J.S.T., Nadarajah, C., Ong, L.S. and Ng, H.W., “The Support of Horizontal Vessel Containing High Temperature Fluids—A Design Study,” ASME Int. Conf. Pressure Vessel Tech. (ICPVT-8), Montreal, Canada (July 1996).

Burgess, M.C., “Performance Testing of Bonded and Weldable Strain Gages at Elevated Temperatures (up to 290°C),” Proc. Workshop Strain Measurement at High Temperature, R.C. Hurst, ed., JRC Petten (N.H.), the Netherlands (1986).

Hofstoetter, P., “Calibration of High Temperature Strain Gages with the Aid of a Clamping Device,”Strain Gage Transducer Tech.,1,42–44 (1984).

British Standards Institution, “Methods for Calibration of Bonded Electric Resistance Strain Gages,” BSG888: 1988, London (1988).

Yokoyama, T., “A Microcomputer Aided Four-point Bend Test System for Determining Uniaxial Stress-strain Curves,”ASTM. J. Testing Eval.,16 (2),198–204 (1988).

Ray, S.K. andGrandt, A.F., Jr., “Fatigue Crack Closure of Surface Flaws Loaded in Pure Bending,Experimental Mechanics,28 (3),273–280 (1988).

Wu, T.T., Ma, L.C. and Zhao, L.B., “Development of Temperature Compensated Resistance Strain Gages for Use to 700°C,” Proc. 4th SESA Congress Exp. Mech., Boston, MA (1980).

American Society for Testing and Materials, “Standard Test Methods for Performance Characteristics of Metallic Bonded Resistance Strain Gages,”Annual Book of ASTM standards, sec. 5, Metals: Tests Methods and Analytical Procedures, Vol. 03.01, American Society for Testing and Materials, Philadelphia, PA (1992).

Ng, H.W., “On the Extension and Verification of the Bree Diagram,”Doctoral thesis; Department of Mechanical Engineering, University of Liverpool, United Kingdom (1981).

Measurements Group Inc., “Strain Gage Installation with Mbond 43-B, 600 and 610 Adhesive Systems,” Instruction Bulletin B-130-14 (1979).

Tokyo Sokki Kenkyujo Co., Ltd (TML), “Direction for Use of TML Strain Gages and Adhesives,” TML Pam E-105 F.

Wey, P., “Evaluation of Strain Gage Performance at Elevated Temperatures, Project A12, School of Mechanical and Production Engineering, Nanyang Technological University, Singapore (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ng, H.W., Wey, P. Strain gage evaluation with four-point bending at moderate temperatures. Experimental Mechanics 37, 237–244 (1997). https://doi.org/10.1007/BF02317413

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02317413