Abstract

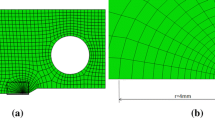

The transient thermal-stress concentrations produced by cracks, sharp and round notches, and fillets, in plates were measured photoelastically and compared to values computed numerically by finite element and finite-difference techniques. The stresses near the tips of the cracks and the notches were singular and observed to agree with isothermal linear elastic fracture mechanics. Stresses near the root of the fillets were always less than the theoretical maximum, αE(T−T initial ), but often greater than the maximum stresses measured in a straight-edged plate subjected to similar thermal conditions.

Similar content being viewed by others

Abbreviations

- A :

-

area

- b :

-

length of crack

- Bi :

-

Biot modulus (hW/k)

- d :

-

diameter

- E :

-

modulus of elasticity

- f :

-

fringe order

- h :

-

film heat-transfer coefficient

- K :

-

stress-concentration factor, stress-intensity factor

- \(\bar K\) :

-

generalized stress-intensification factor

- k :

-

coefficient of thermal conductivity

- L :

-

length of plate

- M :

-

moment

- P :

-

normal tensile load

- r :

-

radius

- t :

-

time

- T :

-

temperature

- W :

-

width of plate

- x,y :

-

rectangular Cartesian coordinate (Fig. 1)

- α:

-

coefficient of thermal expansion, half angle of notch

- ζ:

-

nondimensionalx coordinate (x/W)

- τ:

-

nondimensional time (kt/W 2), maximum shear stress

- σij :

-

Cartesian stress components

- κ:

-

coefficient of thermal diffusivity

- ϕ:

-

Airy stress function

- θ:

-

polar angle

- f :

-

fluid

- i :

-

initial

References

Peterson, R. E., Stress Concentration Design Factors and Relations Useful in Making Strength Calculations for Machine Parts and Structural Elements, Wiley, N. Y. (1953).

Lipson, C., Noll, G. C., andClock, L. S., Stress and Strength of Manufactured Parts, McGraw-Hill Book Co., N. Y. (1950).

Gerard, G., andGilbert, A. C., “Photothermoelasticity, an Exploratory Study,”Inl. Appl. Mech.,24,355–360 (1957).

Tramposch, H., andGerard, G., “Correlation of Theoretical and Photothermoelastic Results on Thermal Stresses in Idealized Wing Structures,”Jnl. Appl. Mech.,27,ser E,79–86 (1960).

Becker, H., “An Exploratory Study of Stress Concentrations in Thermal Shock Fields,” Jnl. Eng. Ind., 343–350 (1962).

Becker, H. and Tramposch, H., “Photothermoelastic Investigation of Notched Plates,” New York University Report 59-1 (January 1959).

Timoshenko, S. andGoddier, J. N., Theory of Elasticity, McGraw-Hill Book Co., N. Y. (1951).

Isida, M., “On the Tension of the Strip with Semi-circular Notches,”Jnl. Soc. Mech. Eng.,19 (83),5–10 (1953).

Isida, M., “On the Bending of a Strip with Semi-circular Notches,”Jnl. Soc. Mech. Eng.,19 (87),94–99 (1953).

Emery, A. F., Walker, G. W. and Williams, J. A., “A Green's Function for the Stress Intensity Factors of Edge Cracks and its Application to Thermal Stresses,” (Paper 68-WA/MET-19), to be published in ASME, Jnl. Basic Eng.

Williams, M. L., “Stress Singularities, Adhesion and Fracture,” Proc. Fifth National Congress of Applied Mechanics, 451–464 (1966).

Emery, A. F. and Segedin, C. M., “Numerical Computation of Plane Stress Intensity Factors for Symmetrical Loads,” Report SCL-DC-67-130, Sandia Laboratory, Livermore, California, (1968).

Carslaw, H. S. andJaeger, J. C., Conduction of Heat in Solids, Oxford University Press, London (1947).

Mal, A. K., “Dynamic Stress Intensity Factor for a Non-axisymmetric Loading of a Penny-shaped Crack,” Intern. Jnl. Eng. Sci.,6 (December 1968).

Additional information

J. A. Williams was Graduate Student (presently with the U. S. Air Force), and J. Avery was Graduate Student (presently with U. S. Army), Univerity of Washington, Seattle, Washington.

Rights and permissions

About this article

Cite this article

Emery, A.F., Williams, J.A. & Avery, J. Thermal-stress concentration caused by structural discontinuities. Experimental Mechanics 9, 558–564 (1969). https://doi.org/10.1007/BF02316658

Issue Date:

DOI: https://doi.org/10.1007/BF02316658