Summary

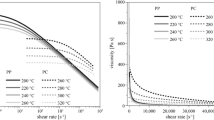

Under practical mould filling conditions one always observes an interaction between polymer flow and heat transfer. A rather rough description of this process is given in the form of a dynamic model for the growth of the solidifying layer. A consideration is added concerning the usefulness of the birefringence pattern, which is observed in the moulded sample, as a source of information about previous melt flow during mould filling. The rubberlike stress-optical behaviour of polymer melts is advocated as a powerful means in finding the thickness of the so-called freeze-off layer and in tracing back the development of shear stresses in the vicinity of the wall during injection.

Zusammenfassung

In der Praxis des Spritzgießens beobachtet man immer ein Zusammenspiel zwischen Fließvorgang und Wärmeübertragung. Eine ziemlich grobe Beschreibung dieses Vorgangs wird in der Form eines dynamischen Modells zur Berechnung des Anwachsens der erstarrenden Schicht gegeben. Hinzugefügt wird eine Betrachtung über das Doppelbrechungs-Streifensystem, wie man es im Spritzling findet, und seine Verwendbarkeit als Informationsquelle für den Fließvorgang während des Füllens. Das gummiartige spannungsoptische Verhalten der Polymerschmelzen wird als sehr geeignetes Hilfsmittel zur Bestimmung der Dicke der während des Einspritzens erstarrten Schicht anempfohlen. Ebenso sollte sich hieraus die Möglichkeit ergeben, den während der Injektion auftretenden Verlauf der Schubspannungen in Wandnähe zurückzuverfolgen.

Similar content being viewed by others

Abbreviations

- a :

-

heat diffusivity of polymer melt m2 s−1

- b :

-

temperature coefficient of viscosity K−1

- B :

-

breadth of mould channel m

- c :

-

heat capacity of polymer melt j kg−1 K−1

- C :

-

stress-optical coefficient of melt m2 N−1

- D :

-

reduced flow rate in rectangular duct s−1

- h :

-

heat-transfer coefficient j K−1 s−1 m−2

- Gz:

-

Graetz-Number (4H2 \(\bar v\))

- H :

-

half height of mould channel m

- L :

-

length of mould channel m

- Nu:

-

Nusselt-Number (2H h/λ)

- n :

-

refractive index tensor (deviatoric components)

- Δn :

-

flow birefringence

- p :

-

Cauchy stress tensor (deviatoric components)

- P :

-

pressure at the mould wall N m−2

- Q :

-

volumetric flow rate m3 s−1

- T :

-

temperature K

- T i :

-

injection temperature

- T l :

-

temperature at which flow virtually stops in the channel

- T m :

-

mould temperature

- T g :

-

glass-transition temperature

- t :

-

time s

- t i :

-

injection time

- \(\bar v\) :

-

average velocity of flowing polymer m s−1

- x :

-

coordinate perpendicular to large surface of sample (of mould)

- z :

-

coordinate in the flow direction

- δ :

-

thickness of stagnant layer m (atT l)

- δ ∞ :

-

steady state thickness of stagnant layer (atT l,∞ )

- δ 0 :

-

optically detectable freeze-off thickness (atT g )

- λ :

-

heat conductivity of polymer melt j K−1 s−1 m−1

- ρ :

-

density of the polymer melt kg m−3

- τ :

-

dimensionless time (eq. [2])

- ψ :

-

dimensionless layer thickness (eq. [3])

- χ :

-

extinction angle (eq. [17])

References

Schenkel, G., Plastics Extrusion Technology and Theory (London 1966);Tadmor, Z., I. Klein, Engineering Principles of Plasticating Extrusion (New York 1970);Fenner, R. T., Extruder Screw Design (London 1970).

Janssen, L. P. B. M., A Phenomenological Study of Twin Screw Extruders (Delft 1976).

Takserman-Krozer, R., G. Schenkel, G. Ehrmann Rheol. Acta14, 1066 (1975).

Bernhardt, E. L. (ed.), Processing of Thermoplastic Materials, Chapter 5, contribution byC. E. Beyer, Role of Temperature, Pressure and Time (New York 1959).

McKelvey, J. M. Polymer Processing, Chapter 13 (J. Wiley and Sons, New York 1962).

Spencer, R. S., Gilmore, G. D. Mod. Plastics27, 97 (1950);28, 117 (1951).

Pearson, J. R. A. Mechanical Principles of Polymer Melt Processing (Pergamon, Oxford 1966).

Woebken, W. Kunststoffe51, 547 (1961);Berger, J. O., C. G. Gogos, Polymer Eng. Sci.13, 102 (1973);White, J. L., Polymer Eng. Sci.15, 44 (1975);Williams, G., H. A. Lord, Polymer Eng. Sci.15, 569 (1975);Han, Ch. D., J. Appl. Polymer Sci.18, 3581 (1974);Basov, N. I., I. I. Felipchuk, Plaste & Kautschuk22, 813 (1975);Menges, G. et al., Berichte zum 8. Kunststoff-technischen Kolloquium, Aachen, March 1976.

Henke, S. J., C. E. Smith, R. F. Abbott Polymer Eng. Sci.15, 79 (1975).

Kantz, M. R., H. D. Newman, F. H. Stigale J. Appl. Polymer Sci.16, 1249 (1972).

Wales, J. L. S., J. van Leeuwen, R. van der Vijgh Polymer Eng. Sci.12, 358 (1972).

Menges, G., G. Wübken Plastverarbeiter23, 318 (1972);Wübken, G., Plastverarbeiter26, 17 (1975).

Brydson, J. A. Flow Properties of Polymer Melts, p. 99 (Iliffe, London 1970).

Barrie, I. T. Plast. Polymer38, 47 (1970).

Tadmor, Z. J. Appl. Polymer Sci.18, 1753 (1974).

Wales, J. L. S., The Application of Flow Birefringence to Rheological Studies of Polymer Melts, Monograph (Delft University Press 1976).

Lodge, A. S. Nature176, 838 (1955);Philippoff, W., Nature178, 811 (1956);Gortemaker, F. H., M. G. Hansen, B. de Cindio, H. Janeschitz-Kriegl, Rheol. Acta15, 242 (1976).

Brinkman, H. C. Appl. Sci. Res.A2, 120 (1951).

Winter, H. H. Polymer Eng. Sci.15, 84 (1975).

Bird, R. B., W. E. Stewart, E. N. Lightfoot Transport Phenomena, p. 363 (J. Wiley, New York 1962).

Schlichting, H. Grenzschichttheorie,Braun, Karlsruhe 1965, Boundary Layer Theory (McGraw-Hill, New York 1955).

Morris, R. H., D. D. Streid Am. Soc, Mech. Engrs. Trans.62, 525 (1940).

Ferry, J. D. Viscoelastic Properties of Polymers, 2nd ed., p. 307 (J. Wiley, New York 1970).

Ref. 5), p. 41.

Atkinson, B., M. P. Brocklebank, C. C. H. Card, J. M. Smith Am. Ind. Chem. Eng. J.15, 548 (1969);Brocklebank, M. P., J. M. Smith, Rheol. Acta9, 396 (1970).

Brandrup, J., E. H. Immergut Polymer Handbook (Interscience, New York 1966).

Wales, J. L. S., J. L. den Otter, H. Janeschitz-Kriegl Rheol. Acta4, 146 (1965).

Treloar, L. R. G. The Physics of Rubber Elasticity, 3rd ed. (Clarendon, Oxford 1975).

Gortemaker, F. H., H. Janeschitz-Kriegl, K. te Nijenhuis Rheol. Acta15, 487 (1976).

Elias, H. G. Makromoleküle, 3rd ed., p. 341 (Hüthig & Wepf, Basel 1975).

Han, Ch. D. Rheology in Polymer Processing (Academic Press, New York 1976).

Author information

Authors and Affiliations

Additional information

With 4 figures and 1 table

Rights and permissions

About this article

Cite this article

Janeschitz-Kriegl, H. Injection moulding of plastics: Some ideas about the relationship between mould filling and birefringence. Rheol Acta 16, 327–339 (1977). https://doi.org/10.1007/BF01534086

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01534086