Summary

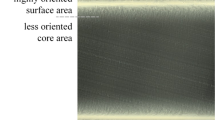

In continuation of a previous investigation a simple analytical expression is derived in closed form for the thickness distribution of the “freeze-off” layer which is vitrified at the (flat) wall of an oblong rectangular cavity. As has been pointed out previously, this layer is marked for amorphous polymers by the molecular orientation (birefringence pattern) in the moulded sample. One can show that a more detailed study with the aid of the coupled equations of energy and of motion will not furnish essential improvements. Problems of polymer physics like glass transition or crystallization kinetics at extreme rates of cooling and shearing must be solved first.

Zusammenfassung

In Fortsetzung einer früheren Untersuchung wurde ein einfacher analytischer Ausdruck in geschlossener Form für die Dickenverteilung der „eingefrorenen“ Schicht abgeleitet, die an der (flachen) Wand eines langgestreckten rechteckigen Formnestes während des Einspritzvorgangs glasig erstarrt. Wie früher auseinandergesetzt wurde, wird diese Schicht bei amorphen Polymeren durch die Molekülorientierung (Doppelbrechungsmuster) im gespritzten Formteil markiert. Man kann zeigen, daß eine eingehendere Studie mit Hilfe der gekoppelten Energie- und Impulsgleichungen keine essentiellen Verbesserungen bringt. Probleme der Polymerphysik, wie Glasübergang oder Kristallisationskinetik bei extremen Abkühlungs- und Schergeschwindigkeiten, müssen erst gelöst werden.

Similar content being viewed by others

Abbreviations

- a :

-

heat diffusivity of polymer melt (averaged overT) [m2s−1]

- B :

-

breadth of mould cavity [m]

- Br :

-

Brinkman number (\(2P'\bar \upsilon H^2 /\lambda (T_i - T_l )\))

- c :

-

heat capacity of polymer melt (averaged overT) [J kg−1 K−1]

- F 0 :

-

Fourier number (at i/4H 2)

- h ∥ :

-

heat transfer coefficient by melt flow [J K−1 s−1 m−2]

- h ⊥ :

-

heat transfer coefficient by layer growth [J K−1 s−1 m−2]

- H :

-

half height of mould cavity [m]

- L :

-

length of mould cavity [m]

- n :

-

exponent in eq. [18] (= 0.417)

- Nu :

-

Nußelt number (2Hh/λ)

- P′ :

-

pressure gradientdP/dz in mould [N m−3]

- t :

-

time [s]

- t i :

-

injection time [s]

- T g :

-

glass transition temperature of polymer [K]

- T i :

-

injection temperature of polymer melt [K]

- T l :

-

stagnation temperature [K]

- T m :

-

mould wall temperature [K]

- \(\bar \upsilon \) :

-

speed of flow front during mould filling [m s−1]

- x :

-

coordinate perpendicular to mould wall [m]

- z :

-

coordinate in the injection direction [m]

- δ :

-

thickness of stagnant layer (atT l) [m]

- δ 0 :

-

optically detectable freeze-off thickness [m]

- δ + :

-

apparent layer thickness (atT i) [m]

- Δ :

-

dimensionless freeze-off thickness (=δ 0/2H)

- ζ :

-

dimensionless distance from entrance (=z/L)

- ζ m :

-

dimensionless coordinate of layer maximum

- θ g :

-

dimensionless temperature (= (T i −T l)/(T g −T m))

- θ i :

-

dimensionless temperature (= (T i −T l)/(T i −T m))

- θ l :

-

dimensionless temperature (= (T i −T l)/(T l −T m))

- η i :

-

viscosity of polymer atT i [N s m−3]

- η l :

-

viscosity of polymer atT l [N s m−3]

- λ :

-

heat conductivity of polymer melt (averaged) [J K−1 s−1 m−1]

- ρ :

-

density of polymer melt (averaged) [kg m−3]

- τ :

-

dimensionless time (eq. [11])

- τ + :

-

dimensionless parameter (eqs. [19a] and [19b])

- ψ :

-

dimensionless layer thickness (eq. [12])

- ψ + :

-

dimensionless parameter (eq. [20a])

- Ω :

-

dimensionless parameter (eqs. [11a] and [11b])

References

Janeschitz-Kriegl, H., Rheol. Acta16, 327 (1977).

Wales, J. L. S., J. van Leeuwen, R. van der Vijgh, Polym. Engng. & Sci.12, 359 (1972).

Dietz, W., J. L. White, E. S. Clark, Polym. Engng. & Sci.18, 273 (1978).

Hellmeyer, H.-O., Ein Beitrag zur Automatisierung des Spritzgießprozesses, Dissertation TH Aachen (1977).

Thienel, P., The Filling Phase in Injection Moulding of Thermoplastics, Dissertation TH Aachen (1977).

Van Krevelen, D. W., Properties of Polymers (2. ed.), p. 342, Elsevier (1976);D. W. van Krevelen, P. J. Hoftyzer, Angew. Makromol. Chemie52, 101 (1976).

Tadmor, Z., J. Appl. Polym. Sci.18, 1753 (1974).

Van Krevelen, D. W., Chimia32, 279 (1978).

Brandrup, J., E. H. Immergut, Polymer Handbook, Interscience (New York, London, Sydney 1966).

Author information

Authors and Affiliations

Additional information

Formerly at Delft University of Technology, Delft (The Netherlands).

With 3 figures and 1 table

Rights and permissions

About this article

Cite this article

Janeschitz-Kriegl, H. Injection moulding of plastics. Rheol Acta 18, 693–701 (1979). https://doi.org/10.1007/BF01533343

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01533343