Abstract

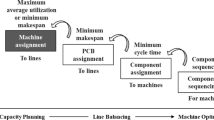

Populating printed circuit boards is one of the most costly and time-consuming steps in electronics assembly. At the beginning of each work order, three decisions are required: (1) a sequence must be specified for placing the individual components on the board; (2) tape reels must be assigned to positions on the magazine rack; and (3) a retrieval plan must be determined should the same component type be assigned to more than one magazine slot. Collectively, these problems can be modeled as a nonlinear integer program. In this paper, we develop a series of algorithms for solving each using an iterative two step approach.

Initially, a placement sequence is generated with a weighted, nearest neighbor traveling salesman problem (TSP) heuristic; the two remaining problems are then formulated as a quadratic integer program and solved with a Lagrangian relaxation scheme. As a final step, the current magazine assignments are used to update the placement sequence, and the entire process is repeated.

Our ability to deal, at least in part, with simultaneous machine operations represents the major contribution of this work. The methodology was simulated for a set of boards obtained from Texas Instruments and theoretically compared with a heuristic currently in use.

Similar content being viewed by others

References

Ahmadi, J., Grotzinger, S. and Johnson, D., “Component Allocation and Positioning for a Dual Delivery Placement Machine,”Operations Research, Vol. 36, No. 2, pp. 176–191 (1988).

Ahmadi, J., Grotzinger, S. and Johnson, D., “Emulating Concurrency in a Circuit Card Assembly System,”International Journal of Flexible Manufacturing Systems, Vol. 3, No. 1, pp. 45–70 (1991).

Archetti, F., Grotzinger, S. and Sciomachen, A., “Petri Net Modeling of a Highly Concurrent Machine,”Proceedings of the 5th International Conference on Systems Engineering, Wright State University, Dayton, Ohio, pp. 389–393 (September 1987).

Ball, M.O. and Magazine, M.J., “Sequencing of Insertions in Printed Circuit Board Assembly,”Operations Research, Vol. 36, No. 2, pp. 192–201 (1988).

Bard, J.F., “A Heuristic for Minimizing the Number of Switches on a Flexible Machine,”IIE Transactions, Vol. 20, No. 4, pp. 382–391 (1988).

Bazaraa, M.S. and Shetty, C.M.,Nonlinear Programming: Theory and Algorithms, John Wiley & Sons, Inc., New York (1979).

Berrada, M. and Stecke, K.E., “A Branch and Bound Approach for Machine Load Balancing in Flexible Manufacturing Systems,”Management Science, Vol. 32, No. 10, pp. 1316–1335 (1986).

Bertsekas, D.P., “A Unified Framework for Primal-Dual Methods in Minimum Cost Network Flow Problems,”Mathematical Programming, Vol. 32, pp. 125–145 (1985).

Bowlby, R., “The DIP May Take Its Final Bows,”IEEE Spectrum, pp. 37–42 (June 1985).

Clayton, R.W., “Printed Circuit Board Component Insertion Optimization,” Master's thesis, Dept. of Mechanical Engineering, University of Texas, Austin, Texas (1989).

Danusaputro, S., Lee, C.-Y. and Martin-Vega, L.A., “An Efficient Algorithm for Drilling Printed Circuit Boards,” Working Paper, Dept. of Industrial and Systems Engineering, University of Florida, Gainesville, Florida (January 1989).

Darby-Dowman, K. and Lewis, H.S., “Lagrangian Relaxation and the Single-Source Capacitated Facility-Location Problem,”Operations Research, Vol. 39, No. 11, pp. 1035–1040 (1988).

Feo, T.A., Zachos, L. and Bard, J.F., “A Simulation Analysis of PCB Assembly Operations at Texas Instruments,” Working Paper No. 14-90, Dept. of Mechanical Engineering, University of Texas, Austin, Texas (1990).

Fisher, M.L., “The Lagrangian Relaxation Method for Solving Integer Programming Problems,”Management Science, Vol. 27, No. 1, pp. 1–18 (1981).

Geoffrion, A., “Lagrangian Relaxation for Integer Programming,”Mathematical Programming Study, Vol. 2, pp. 82–114 (1974).

Grotzinger, S., “Positioning for a Dual Delivery Placement Machine,” Research Report RC 13908 (#62483), IBM Research Division, Yorktown Heights, New York (1988).

Grotzinger, S. and Sciomachen, A., “A Petri Net Characterization of a High Speed Placement Machine,”Proceedings of the 38th Electronic Components Conference, Los Angeles, California, pp. 64–68 (May 1988).

Hankins, S.L. and Rovito, V.P., “A Comparison of Two Tool Allocation and Distribution Strategies for FMS,”Proceedings of the First ORSA/TIMS Special Interest Conference on Flexible Manufacturing Systems: Operations Research Models and Applications, K.E. Stecke and R. Suri (eds.), Ann Arbor, Michigan, pp. 272–277 (1984).

Kim, Y.-D. and Yano, C.A., “An Iterative Approach to System Setup Problems in Flexible Manufacturing Systems,”International Journal of Flexible Manufacturing Systems, Vol. 2, No. 2, pp. 183–209 (1992).

Lawler, E.L., Lenstra, J.K., Rinnooy Kan, A.H.G. and Shmoys, D.B. (eds.),The Traveling Salesman Problem, John Wiley & Sons, New York (1986).

Leipala, T. and Nevalainen, O., “Optimization of the Movements of a Component Placement Machine,”European Journal of Operational Research, Vol. 38, No. 2, pp. 167–177 (1989).

Liggett, R.S., “The Quadratic Assignment Problem: An Experimental Investigation of Solution Strategies,”Management Science, Vol. 27, No. 4, pp. 442–458 (1981).

Lofgren, C.B. and McGinnis, L.F., “Dynamic Scheduling for Flexible Printed Circuit Card Assembly,”Proceedings of the 1986 IEEE Conference on Systems, Man, and Cybernetics, San Francisco, California, pp. 1294–1297 (1986a).

Lofgren, C.B. and McGinnis, L.F., “Soft Configuration in Automated Insertion,”Proceedings of the 1986 IEEE International Conference on Robotics and Automation, San Francisco, California, pp. 138–142 (April 1986b).

Marcoux, P.P., “Putting on the Chips,”Printed Circuit Fabrication, Vol. 9, No. 3, pp. 81–84 (March 1986).

Parker, R.G. and Rardin, R.L.,Discrete Optimization, Academic Press, New York (1988).

Randhawa, S.U., McDowell, E.D., and Faruqui, S.D., “An Integer Programming Application to Solve Sequence Mix Problems in Printed Circuit Board Production,”International Journal of Production Research, Vol. 23, No. 3, pp. 543–552 (1985).

Stecke, K.E., “Formation and Solution of Nonlinear Integer Production Planning Problems for Flexible Manufacturing Systems,”Management Science, Vol. 29, No. 3, pp. 1273–1288 (1983).

Tang, C.S. and Denardo, E.V., “Models Arising from a Flexible Manufacturing Machine, Parts I & II,”Operations Research, Vol. 36, No. 5, pp. 767–684 (1988).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bard, J.F., Clayton, R.W. & Feo, T.A. Machine setup and component placement in printed circuit board assembly. Int J Flex Manuf Syst 6, 5–31 (1994). https://doi.org/10.1007/BF01324873

Issue Date:

DOI: https://doi.org/10.1007/BF01324873