Conclusions

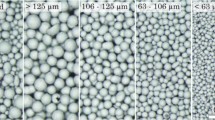

In the high-speed pressing of powders it is possible to distinguish several processes with differnt operative mechanisms of powder particle deformation. Deformation mechanisms are determined by a complex criterion whose value depends on the mass velocity, since, thermal diffusivity, density, and hardness of particles. An understanding of the particle deformation mechanisms is of practical value. In the pressing of fine powders it is best to employ a quasistatic process represented by field II. To obtain compacts of high density and strength, use should be made of coarse powder fractions or pregranulated fine fractions in order to create conditions corresponding to field III. Incidentally, granulation not only increases the size of particles but also lowers their hardness, which is desirable in the case of difficult-to-press materials. Of particular interest is the pressing of rapidly quenched powders, which do not readily lend themselves to heat treatment. In such a case parameters corresponding to field IV should be chosen, and strength will then be imparted to compacts by melting and rapid solidification of the particle surfaces.

Similar content being viewed by others

Literature cited

O. V. Roman, V. F. Nesterenko, and I. M. Pikus, “Effect of powder particle size on the explosive pressing process,” Fiz. Goreniya Vzryva, No. 5, 102–105 (1979).

O. V. Roman, V. G. Gorobtsov, and I. M. Pikus, “The forming of powder materials by explosive loading method,” in: Powder Metallurgy [in Russian], No. 7, Vyshéishya Shkola, Minsk (1983), pp. 2–8.

V. F. Nesterenko, “Scope of shock-wave methods of preparations and compaction of rapidly quenched materials,” Fiz. Goreniya Varyva, No. 6, 85–97 (1985).

N. A. Kil'chevskii, Dynamic Contact Compression of Solids. Impact [in Russian], Naukova Dumka, Kiev (1976).

J. Hale, Theory of Functionally Differential Equations [Russian translation], Mir, Moscow (1984).

V. A. Likhobanin, A. P. Mantroshin, P. O. Pashkov, and V. O. Rogrozin, “Structure and properties of blanks produced from powders subjected to high-speed loading,” in: Metal Science and Strength of Materials [in Russian], Volgogr. Politekh. Inst., Volgograd (1971), pp. 56–61.

W. H. Gourdin, “Energy distribution and microstructural modification in dynamically consolidated metal powders,” J. Appl. Phys., No. 1, 172–181 (1984).

G. B. Olson, J. F. Mescol, and M. Azren, “Localization of energy during impact loading,” in: Shock Waves and High-Speed Metal Deformation Phenomena [Russian translation], Metallurgiya, Moscow (1984), pp. 67–89.

V. G. Gorobtsov, A. P. Mirilenko, and I. M. Pikus, “Determination of the Gruneisen coefficient and shock-wave parameters of a porous solid under incomplete compression conditions,” Fiz. Goreniya Vzryva, No. 1, 54–57 (1987).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 11(323), pp. 14–19, November, 1989.

Rights and permissions

About this article

Cite this article

Roman, O.V., Mirilenko, A.P. & Pikus, I.M. Effect of high-speed loading conditions on the pressing mechanism. Powder Metall Met Ceram 28, 840–844 (1989). https://doi.org/10.1007/BF01198890

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01198890