Summary

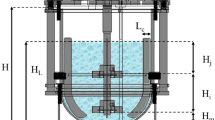

Cephalosporin C was produced with the moldCephalosporium acremonium in a 20 1 stirred tank reactor with 100 kg/m3 peanut flour in fed-batch operation. The growth and product formation was followed by on-line analysis of the broth composition. The cell concentration was estimated from the RNA-content of the cells. By optimization of the fed-batch operation and by increasing the phosphate content in the broth, a final cephalosporin C concentration of 12 kg/m3 was attained.

Similar content being viewed by others

Abbreviations

- CPC:

-

cephalosphorin C

- DAC:

-

deacetylcephalosporin C

- DAOC:

-

deacetoxycephalosporin C

- k L a :

-

volumetric mass transfer coefficient

- MMBS:

-

2-Hydroxy-4-methylmercaptobutyric acid

- PABAH:

-

p-Hydroxybenzoicacidhydrazid

- RNA:

-

ribonucleic acid

- RQ:

-

respiratory quotient

- \(Q_{O_2 } \) :

-

oxygen transfer rate

- \(Q_{CO_2 } \) :

-

CO2-production rate

- t :

-

fermentation time

References

Bayer T, Herold T, Hiddessen R, Schügerl K (1986) On-line monitoring of media components during the production of cephalosporin C. Anal Chim Acta 190:213–219

Einsele A, Finn RK, Samhaber W (1985) Mikrobiologische und biochemische Verfahrenstechnik. Verlag Chemie, Weinheim

Herold T (1986) Cephalosporin C Produktion im Rührkessel. Dissertation, Universität Hannover

Hiddessen R (1987) Entwicklung und Einsatz eines Automatisierungssystems zur on-line Überwachung und Steuerung prozeßrechnergekoppelter Bioreaktoren. Dissertation, Universität Hannover

Küenzi MT (1979) Comparison of the fermentation kinetics ofCephalosporium acremonium in shake flasks and fermentors by means of ribonucleic acid analysis. Biotechn Lett 18:127–132

Küenzi MT (1980) Regulation of cephalosporin synthesis inCephalosporium acremonium by phosphate and glucose. Arch Microbiol 128:8–83

Matsumura M, Imanaka T, Yoshida T, Taguchi H (1978) Effect of glucose and methionine consumption rates on Cephalosporin C production byCephalosporium acremonium. J Ferment Technol 56:345

Meyer HD, Kuhlmann W, Lübbert A, Schügerl K (1987) Development of a microcomputer-based system for singlesstirred bioreactors and their cascasde. J Chem Tech Biotechnol 40:19–32

Smith A (1985) Cephalosporins. In: Moo-Young M (ed) Comprehensive biotechnology: Vol. 3. Pergamon Press, Oxford, pp 163–185

Zanca DM, Martin JF (1983) Carbon catabolite regulation of the conversion of penicillin N into cephalosporin C. J Antibiot 36:700

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Herold, T., Bayer, T. & Schügerl, K. Cephalosporin C production in a stirred tank reactor. Appl Microbiol Biotechnol 29, 168–173 (1988). https://doi.org/10.1007/BF00939302

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00939302