Conclusions

-

1.

According to thermodynamic calculations, in the initial stage boronizing may occur through a dual mechanism: simultaneous active diffusion of atomic boron and direct reaction resulting in the formation of higher iron borides.

-

2.

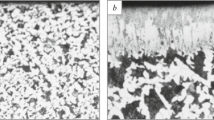

It is demonstrated that in powder boronizing the nature of the activator has a pronounced effect on the concentration and character of distribution of pores in the boride layer and hence on the quality of the resultant coating.

-

3.

On the basis of data yielded by thermodynamic calculations and experimental results it is shown that iron oxides can be successfully employed as activators of the powder boronizing process.

-

4.

Experiments have shown that a powder mixture consisting of 80% boron carbide and 20% magnetite is comparable in activity to mixtures with halide activators, but surpasses them in other respects: It possesses good processing characteristics, is nontoxic, shows no sinterability, and is capable of being used repeatedly without regeneration.

-

5.

Mixtures with oxygen transport of boron offer greatest promise for the boronizing of high-alloy stainless steels.

Similar content being viewed by others

Literature cited

L. A. Sosnovskii et al., “Effects of activating additions on diffusional impregnation processes,"; Poroshk. Metall., No. 12, 41–48 (1973).

A. N. Krestovnikov and V. N. Vygdorovich, Chemical Thermodynamics [in Russian], Metallurgiya, Moscow (1973).

A. V. Smirnov et al., “Physicochemical principles of gaseous boronizing,"; in: Protective Coatings on Metals [in Russian], No. 9, Naukova Dumka, Kiev (1975), pp. 45–49.

V. D. Derkach et al., “Mechanism of boron supply to the surface being impregnated during boronizing in a technical boron carbide powder,"; in: Chemicothermal Treatment of Metals and Alloys [in Russian], Izd. Bel. Politekh. Inst., Minsk (1971), pp. 142–149.

G. V. Samsonov et al., Boron and Its Compounds and Alloys [in Russian], Izd. Akad. Nauk Ukr. SSR, Kiev (1960).

G. V. Samsonov and A. P. épik, Coatings of Refractory Compounds [in Russian], Metallurgiya, Moscow (1973).

N. P. Besedin, “Physicomechanical principles of the boronizing of steel,"; Author's Abstract of Candidate's Dissertation, Moscow (1953).

A. Matuschka, “Borieren: Ein Blick uber den derzeitigen Stand der Technik,"; Tech. Rundschau,6, No. 30, 10–14 (1974).

Muta Akinori et al., “Boronizing of steel surfaces with a mixture of boron carbide and alkali metal carbonates,"; Nihon Kindzoku Gakkaishi, J. Jpn. Inst. Met.,32, No. 5, 440–449 (1968).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 4(196), pp. 26–30, April, 1979.

Rights and permissions

About this article

Cite this article

Yakhnina, V.D., Kozlov, A.M. & Luk'yanitsa, A.I. Physicochemical characteristics of powder boronizing. Powder Metall Met Ceram 18, 237–240 (1979). https://doi.org/10.1007/BF00793807

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00793807