Conclusions

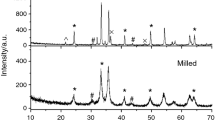

Investigations have shown that the decomposition of metallic formates is accompanied by a loosening of the structure of their crystals, the rate of the process depending on the nature of the metals. In the stages of decomposition the crystals acquire a porous, spongy structure and disintegrate under the action of gases being evolved and internal stresses being generated. Under these conditions the specific surfaces of specimens rapidly grow. The mean particle size of the end products of the reaction is 0.1–0.3μ, with a specific surface of about 60 m2/g. Exceptions are nickel and copper, whose particles have a strong tendency to sinter together, with the formation of agglomerates. X-ray studies have established that at various stages of the thermal decomposition process the intensities of reflections characterizing the starting salts change, and new reflections appear, indicating the formation of metallic phases in finely divided form. The method of thermal decomposition of metallic formates is suitable for the preparation of very fine powders of pure metals, from which various sintered materials can be produced.

Similar content being viewed by others

Literature cited

L. F. Freidlina and G. F. Bulanova, “Thermal decomposition of lead formate and formic acid on metallic lead,” Izv. Akad. Nauk SSSR, No. 2, 555–568 (1937).

Yu. I. Khimchenko, “Formation and properties of metal-polymer materials,” Candidate's Dissertation, Institute of General and Inorganic Chemistry, Academy of Sciences of the Ukrainian SSR, Kiev (1965).

Yu. I. Khimchenko, L. S. Radkevich, and É. M. Natanson, “Processes of formation and thermal behavior of metal-polymer materials based on Kapron (polycaprolactam resin),” in: Physicochemical Mechanics and Lyophilic Character of Disperse Systems [in Russian], Vol. 3, Nauk. Dumka, Kiev (1971), pp. 85–90.

É. M. Natanson, Yu. I. Khimchenko, L. S. Radkevich, and M. G. Lysenko, “Conditions of formation of metal-polymer materials based on ÉD-5 epoxy resin and finely divided iron, cobalt, and nickel,” Kolloidn. Zh.,31, No. 5, 726–729 (1969).

N. E. Buyanova, G. B. Gudkova, and A. P. Karnaukhov, “Determination of the specific surfaces of solids by the argon thermal desorption method,” Kinet. Katal.,6, No. 6, 1085–1091 (1965).

D. Kay (editor), Electron Microscopy Techniques [Russian translation], Mir, Moscow (1965).

V. N. Luk'yanovich, Electron Microscopy in Physicochemical Investigations [in Russian], Izd-vo Akad. Nauk SSSR, Moscow (1960).

É. M. Natanson, Yu. I. Khimchenko, and L. S. Radkevich, “Thermographic and thermogravimetric investigations of the processes of decomposition of iron, cobalt, and nickel formates,” in: Physicochemical Mechanics and Lyophilic Character of Disperse Systems [in Russian], Vol. 1, Nauk. Dumka, Kiev (1968) pp. 162–164.

É. M. Natanson, Yu. I. Khimchenko, and L. S. Radkevich, “Metal-polymer materials based on ÉD-5 epoxy-diane resin and copper,” in: Synthesis and Physical Chemistry of Polymers [in Russian], Nauk. Dumka, Kiev (1966), pp. 123–125.

Author information

Authors and Affiliations

Additional information

Deceased.

Translated from Poroshkovaya Metallurgiya, No. 5(173), pp. 7–13, May, 1977.

Rights and permissions

About this article

Cite this article

Khimchenko, Y.I., Vasilenko, V.P., Radkevich, L.S. et al. Decomposition of iron, cobalt, nickel, and copper formates. Powder Metall Met Ceram 16, 327–332 (1977). https://doi.org/10.1007/BF00791078

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00791078