Conclusions

-

1.

Alloying of carbide-forming elements with austenitic manganese steel increases the strength and hardness. The addition of 0.7% V is particularly effective.

-

2.

At a substantial degree of deformation (above 45%) there is no great difference in the hardness of the steels investigated (HV 500–520).

-

3.

Up to 6.5% Cr and up to 1.24% Mo substantially decreases the susceptibility of austenitic manganese steels to cold brittleness.

-

4.

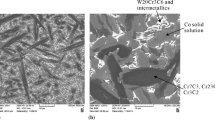

In the process of plastic deformation the α-phase is formed as submicroscopic particles uniformly distributed on the slip planes in the deformed austenite.

-

5.

The austenite in the steels investigated is susceptible to phase transformations from 300 to 600°C. The stability of the austenite is minimum at 500–600°C.

Similar content being viewed by others

Literature cited

V. I. Grigorkin, FMM (1962),14, No. 2.

V. T. Biryulin and V. D. Sadovskii, Transactions of the Institute of Physics of Metals [in Russian], Moscow, Izd. AN SSSR (1956), No. 18.

Additional information

Chelyabinsk Polytechnical Institute, Moscow Institute of Steel and Alloys. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 27–31, October, 1966.

Rights and permissions

About this article

Cite this article

Grigorkin, V.I., Korotushenko, G.V. Properties of austenitic manganese steels alloyed with carbide-forming elements. Met Sci Heat Treat 8, 809–812 (1967). https://doi.org/10.1007/BF00655785

Issue Date:

DOI: https://doi.org/10.1007/BF00655785