Abstract

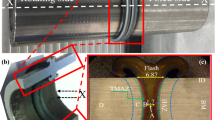

The microstructures of inertia-friction weldments in a rapidly solidified, powder metallurgy Al-8.7Fe-2.8Mo-1V alloy were characterized using light and transmission electron microscopy. Extensive plastic deformation at the weld interface during the welding process was shown to fracture and disperse relatively coarse, spherical dispersoids present in the original base-metal microstructure, thereby resulting in a refined dispersoid size in this region. These fine dispersoids promoted an increase in hardness at the weld interface as compared to the unaffected base metal. Local regions of nonuniform interface deformation at the weld outer periphery resulted in a heterogeneous microstructure comprised of adjacent regions of high and low dispersoid density. The dispersoid-lean regions were characterized by appreciably coarsened alpha grains and a hardness well below that of the base metal. The greater extent of dispersoid-lean regions in welds produced with low axial force promoted preferential weld interface failure during three-point bend testing, while the near absence of these regions in welds produced with high axial force promoted failure in the unaffected base metal remote from the weld.

Similar content being viewed by others

References

S. L. Langenbeck, W. M. Griffith, G. J. Hildeman andJ. W. Simon, in “Rapidly-Solidified Powder Aluminum Alloys, ASTM STP 890”, edited by E. A. Starke Jr and M. E. Fine (American Society for Testing Materials, Philiadelphia, Pennsylvania, 1986) p. 7.

W. A. Baeslack III andS. Krishnaswamy, in “Advances in Welding Science and Technology”, edited by S. A. David (ASM International, Metals Park, Ohio 1987) p. 357.

S. Krishnaswamy andW. A. Baeslack III,Mater. Sci. Engng. 98 (1988) 137.

S. Krishnaswamy, PhD dissertation, The Ohio State University (1989).

W. A. Baeslack III, K. H. Hou andJ. H. Devletian,J. Mater. Sci. Lett. 7 (1988) 944.

Idem, ibid. 8 (1989) 1716.

V. Ananthanarayanan, PhD dissertation, The Ohio State University (1988).

W. A. Baeslack III andK. S. Hagey,Weld. J. Res. Suppl. 67 (1988) 139s.

K. K. Wang, “Friction Welding-Welding Research Council Bulletin No. 204”, (Welding Research Council, New York, 1975).

C. M. Adam andR. G. Bourdeau, in “Rapid Solidification Processing, Principles and Technologies II”, edited by R. Mehrabian, B. H. Kear and M. Cohen (Claitors, Baton Rouge, 1980) p. 246.

S. L. Langenbeck, R. A. Rainen,et al. in “Elevated Temperature Aluminum Alloy Development”, AF-WAL-TR-86-4027 (1986) pp. 6–68.

M. Rao andT. H. Hazlett,Weld. J. Res. Suppl. 49 (1970) 181s.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hou, K.H., Baeslack, W.A. Electron microscopy of inertia-friction weldments in a rapidly solidified Al-Fe-Mo-V alloy. J Mater Sci 25, 2642–2653 (1990). https://doi.org/10.1007/BF00638072

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00638072