Abstract

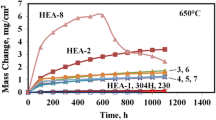

Several alloys (one iron base and five nickel base) were cyclically oxidized in a series of tests in which the higher temperature (1100 or 1200° C) of the cycle was fixed at a level to allow ample oxidation in reasonable time and the lower temperature was variable to allow cycle temperature differences (ΔT s ) of up to 1400°C. The alloys oxidized included those which formed simple oxides such as Al2O3 or Cr2O3, as well as those which formed complex scales. Cooling rates were relatively low to minimize thermal shock effects. Each cycle consisted of 1 hr at the higher temperature and 1/2 hr at the lower temperature. Samples were tested up to 370 cycles. The extent of attack was determined by specific weight change which was continuously monitored. For all nickel alloys, as ΔT increased the extent of spallation increased. This effect was attributed to thermal expansion mismatches between the oxide and the nickel substrate. The FeCrAl alloy was not sensitive to ΔTand resisted spalling at ΔT levels to 1400°C. FeCrAl, and the Al2O3 scale which forms on it, have thermal expansion coefficients which are substantially more alike than any of the other oxide-metal combinations tested.

Similar content being viewed by others

References

C. A. Barrett and C. E. Lowell,Oxid. Met. 9, 307 (1975).

D. L. Douglass,Oxidation of Metals and Alloys (American Society of Metals, Metals Park, Ohio, 1971), pp. 137–156.

P. Hancock and R. C. Hurst,Advances in Corrosion Science and Technology, M. G. Fontana and R. W. Staehle, eds. (Plenum Press, New York, 1974), Vol. 4, pp. 1–84.

J. R. Johnston and R. L. Ashbrook, “Effect of Cyclic Conditions on the Dynamic Oxidation of Gas Turbine Superalloys,” NASA TN D-7614 (April 1974).

J. K. Tien and F. S. Pettit,Metall. Trans. 3, 1587 (1972).

G. D. Oxx,Prod. Eng. (N.Y.)29, 61 (1958).

C. E. Lowell, R. G. Garlick, and B. Henry, “Thermal Expansion in the Nickel-Chromium-Aluminum and Cobalt-Chromium-Aluminum Systems to 1200°C,” NASA TM X-3268 (August 1975).

P. J. Baldock, W. E. Spindler, and T. W. Baker, “An X-Ray Study of the Variation of the Lattice Parameters of Alumina, Magnesia and Thoria up to 2000°C,” AERE-R5674, United Kingdom Atomic Energy Authority Research Group, Harwell (England) (January 1968).

O. H. Kirkorian, “Thermal Expansion of High Temperature Materials,” UCRL-6132, Lawrence Radiation Lab., University of California, Livermore, Calif. (September 6, 1960).

I. Zaplatynsky, “Thermal Expansion of Some Nickel and Cobalt Spinels and Their Solid Solutions,” NASA TN D-6174 (February 1971).

J. D. Latva,Met. Prog. 82, 97 (1962).

C. A. Barrett and C. E. Lowell, “Resistance of Nickel-Chromium-Aluminum Alloys to Cyclic Oxidation at 1100° and 1200°C,” NASA TN D-8255 (1976).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Deadmore, D.L., Lowell, C.E. The effect of ΔT (oxidizing temperature minus cooling temperature) on oxide spallation. Oxid Met 11, 91–106 (1977). https://doi.org/10.1007/BF00612137

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00612137