Abstract

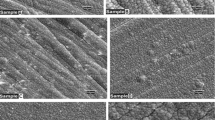

Wire-shaped nickel-based amorphous alloys exhibiting high strength and good ductility combined with a high corrosion resistance were produced for Ni-Pd-Si and Ni-Pd-P alloys by melt spinning in rotating water. The amorphous wires were formed over a relatively wide range from 29 to 82 at % palladium for (Ni-Pd)82Si18 alloys and from 12 to 52 at % palladium for (Ni-Pd)80P20 alloys. The Ni-Pd-Metalloid amorphous wires had a circular cross-section and smooth surface, and their diameters were 80 to 150μm. With increasing nickel content, their tensile strength, σf, increased from 1340 to 1710 MPa and the elongation to fracture, εf, decreased slightly from 2.2% to 1.9%. Cold-drawing the wires was an easy technique to reduce their diameter and to increase σf and εf up to an appropriate value of reduction in diameter. In addition, it is also effective in smoothing the wire surface. Their corrosion resistance was assumed to be sufficiently high since their polarization behaviour in 1 N H2SO4 solution was similar to palladium metal. Cold-drawing did not enhance corrosion and rather decreased apparently the active dissolution current density of some alloys owing to smoothing of the surface.

Similar content being viewed by others

References

M. Hagiwara, A. Indue andT. Masumoto,Met. Trans. 12A (1981) 1027.

Idem, Sci. Rep. Res. Inst. Tohoku Univ. A-29 (1981) 351.

H. S. Chen andE. Coleman.J. Appl. Phys. Lett. 28 (1976) 245.

A. Inoue, N. Yano andT. Masmumoto,J. Mater. Sci. 19 (1984) 3786.

M. Hagiwara, A. Inoue andT. Masumoto,Met. Trans. 13 (1982) 373.

A. Inoue, M. Hagiwara andT. Masumoto,J. Mater. Sci. 17 (1982) 580.

M. Hagiwara, A. Inoue andT. Masumoto,Mater. Sci. Eng. 54 (1982) 197.

T. Masumoto, I. Ohnaka, A. Inoue andM. Hagiwara,Scripta Metall. 15 (1981) 293.

A. Inoue, H. S. Chen, J. T. Krause, T. Masumoto andM. Hagiwara,J. Mater. Sci. 18 (1983) 2743.

T. Masumoto, A. Inoue, M. Hagiwara, I. Ohnaka andT. Fukusako, Proceedings of the 4th International Conference on Rapidly Quenched Metals, Vol. 1, edited by T. Masumoto and K. Suzuki, (The Japan Institute of Metals, Sendai, 1982) p. 47.

I. Ohnaka, T. Fukusako andT. Daido,J. Japan Inst. Metals 45 (1981) 751.

H. S. Chen,Acta Metall. 22 (1974) 1505.

“Metals Databook” (Japan Institute of Metals, 1974) p. 171.

K. Hashimoto, K. Asami, M. Naka andT. Masumoto,Corros. Sci. 19 (1979) 857.

C. A. Pampillo,Scripta Metall. 6 (1972) 915.

S. Takayama andR. Maddin,Acta Metall. 23 (1975) 943.

T. M. Devine,J. Electrochem. Soc. 124 (1977) 38.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Inoue, A., Masumoto, Y., Yano, N. et al. Production of Ni-Pd-Si and Ni-Pd-P amorphous wires and their mechanical and corrosion properties. J Mater Sci 20, 97–104 (1985). https://doi.org/10.1007/BF00555903

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00555903