Abstract

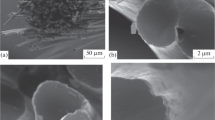

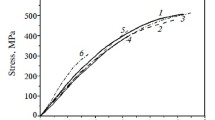

Thornel 50 was continuously coated with pyrolytic carbon from an atmosphere of acetylene. Using resistance heating to raise the temperature of the graphite fibre yarn to 1100 to 1200° C, as much as 60% increase in weight of pyrolytic carbon could be uniformly applied to the surfaces of the individual filaments. The treated fibres gave improved interlaminar shear strengths up to 60 MN m−2 and improved flexural strengths up to 900 MN m−2 in epoxy resin composites. Visual examination of the fractured surfaces indicated that while the adhesion of the resin to the pyrolytic carbon was satisfactory, the adhesion of the pyrolytic carbon to the Thornel 50 fibre surface may have been less satisfactory and led to premature failure. Such continuous one stage treatments of graphite fibres offer advantages in terms of improved handling characteristics, greater oxidation and corrosion resistance, improved wettability, and slightly better impact toughness than other commercially available treated fibres. The resultant increase in the weight of the treated yarn may improve the economic aspects for applications which do not require highly flexible yarns.

Similar content being viewed by others

References

D. W. McKee and V. J. Mimeault, General Electric Technical Information Series, Report No. 70-C 247, July 1970. Available from General Electric Research and Development Center, PO Box 43, Building 5, Schenectady, NY, 12301.

Idem, Nature 224 (1969) 793.

J. V. Larsen, T. G. Smith and P. W. Erickson, Naval Ordnance Laboratory, AD 743, 469, October 1971. Available from National Technical Information Service, US Department of Commerce, 5285 Port Royal Road, Springfield, V. 22151.

J. W. Herrick, 23rd Annual SPI Technical Conference, Reinforced Plastics/Composites Division, 16-A (1968).

J. C. Goan and S. P. Prosen, ASTM Publication STP-452 (1968) 1.

M. Barber, P. Swift, E. L. Evans and J. M. Thomas, Nature 227 (1970) 1131.

J. C. Goan, L. A. Joo' and G. E. Sharpe, 27th Annual SPI Technical Conference, Reinforced Plastics/Composites Institute 21-E (1972).

R. G. Shaver, 24th Annual SPI Technical Conference, Reinforced Plastics/Composites Division 15-B (1969).

E. F. Abrams and R. G. Shaver, Non-Metallic Materials Division, Chemistry Research Department, US Naval Ordnance Laboratory AD 879291 (1972).

M. S. Rashid and C. D. Wirkus, Ceram. Bull. 51 (1972) 836.

P. L. Walker, J. F. Radzowski and G. R. Imperial, J. Phys. Chem. 63 (1959) 133.

J. W. Graydon, B.A.Sc. Thesis, Department of Chemical Engineering and Applied Chemistry, University of Toronto, Toronto, Canada (1970).

Grafil Test Methods (1970), Carbon Fibres Unit, Courtaulds Ltd, PO Box 16, Coventry CV6 5AE, England (1970).

N. L. Hancox and H. Wells, ASME Symposium on Carbon Composites, Albuquerque, New Mexico (1970).

Union Carbide Technical Information Bulletin No. 465-203ij “Thornel” 50 Graphite Yarn, Grade WYG 130 1/2 (1970).

W. D. Claus, Society of the Plastics Industry Conference, Reinforced Plastics/Composites Institute, Section 9-C (1972).

H. Wells, W. J. Colclough and P. R. Groggin, Reinforced Plastics Conferences, Society of the Plastics Industry Lecture (February 1969).

R. Prescott, J. C. Goan, J. E. Hill, L. A. Joo' and T. W. Martin, 27th Annual SPI Technical Conference, Reinforced Plastics/Composites Division, 13-C (1972).

J. C. Morley, Composites 2 (1971) 80.

J. C. Morley, Proc. Roy. Soc. London, A-319 (1970) 117.

N. L. Hancox, Composites 2 (1971) 41.

J. Fuerst, Exxon Enterprises Inc., 1251 Avenue of the Americas, New York, NY 10020 (Comtek Project 1973).

D. J. Pinchin, M.A.Sc. Thesis, Department of Chemical Engineering and Applied Chemistry, University of Toronto, Toronto, Canada (1972).

F. Tuinstra and J. S. Koenig, J. Comp. Mats. 2 (1970) 492.

R. L. Hough, A.I.A.A. J. 3-2 (1965) 291.

J. V. Duffy, US Naval Ordnance Lab NOLTR-73-153, White Oak, Md.; AD-766,782/7WM, August, 1973).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pinchin, D.J., Woodhams, R.T. Pyrolytic surface treatment of graphite fibres. J Mater Sci 9, 300–306 (1974). https://doi.org/10.1007/BF00550955

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00550955