Abstract

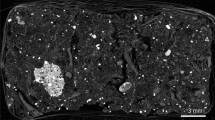

In this study, different molecular weight PEEK materials were used to determine the effect of spherulite size on fracture. Melt processing of the PEEK at different temperatures produced samples of different average spherulite size. A permanganic etching technique was used to reveal the spherulites. It was found that for low molecular weight 150P PEEK, the spherulite size increased with melt processing temperature; but, for the higher molecular weight 450G PEEK, the spherulite size remained approximately constant. Also, the average spherulite size was markedly lower for the material of higher molecular weight. The failure behaviour of these samples was studied using a compact tension test. It was found that the fracture toughness of PEEK varied with processing temperature. Also, the average spherulite size of a PEEK material had a profound influence on the fracture mechanism.

Similar content being viewed by others

References

D. J. Blundell and B. N. Osborn, Polymer 24 (1983) 953.

O. B. Searle and R. H. Pfeiffer, Polym. Eng. Sci. 25 (1985) 474.

D. W. Clegg and A. A. Collyer, “The Mechanical Properties of Reinforced Thermoplastics” (Elsevier Applied Science Publishers, New York, 1984).

G. R. Belbin, Proceedings of the 12th John Player Lecture, London, 1984.

D. J. Kemmish and J. N. Hay, Polymer 26 (1985) 905.

E. J. Stober, J. C. Seferis and J. D. Keenan, ibid. 25 (1984) 1845.

J. Delmonte, “Technology of Carbon and Graphite Fiber Composites”, (Von Nostrand Reinhold, New York, 1981).

J. C. Seferis, A. E. Elia and A. R. Wedgewood, Proceedings of European Meeting on Polymer Processing and Properties, (Plenum Press, New York, 1984) p. 423.

J. C. Seferis, Polym. Compos. 7 (1986) 158.

C. N. Velisaris and J. C. Seferis, Polym. Eng. Sci. 26 (1986) 1574.

W. J. Sichina and P. S. Gill, ANTEC (1985) 293.

C. H. Michler and I. Naumann, Proceedings 17th Europhysics Conference on Macromolecular Physics (Walter de Gruyter, New York, 1986) p. 329.

J. H. Reinshagen and R. W. Dunlap, J. Appl. Polym. Sci. 17 (1973) 3619.

J. R. Collier and L. M. Neal, Polym. Eng. Sci. 9 (1969) 182.

E. B. Morgan, J. Appl. Chem. 4 (1963) 175.

J. V. McLaren, Polymer 4 (1963) 175.

B. Wunderlich, “Macromolecular Physics” (Academic, New York, 1976).

L. W. Kleiner, M. R. Radloff, J. M. Schultz and T. W. Chou, J. Polym. Sci., Polym. Phys. Edn. 12 (1974) 819.

J. L. Way, J. R. Atkinson and J. Nutting, J. Mater. Sci. 9 (1974) 293.

K. Friedrich, Fracture 3 (1977) 1119.

J. M. Schultz, Polym. Eng. Sci. 24 (1984) 770.

R. A. Crick, D. C. Leach, P. J. Meakin and D. R. Moore, J. Mater. Sci. 22 (1987) 2094.

J. Deraux, D. Delimoy, D. Daoust, R. Legras, J. P. Mercier, C. Strazielle and E. Nield, Polymer 26 (1985) 1994.

Jia-Ni Chu, M. S. Thesis, University of Delaware (1988).

R. H. Olley, D. C. Bassett and D. J. Blundell, Polymer 27 (1986) 344.

D. Broek, “Elementary Engineering Fracture Mechanics”; 4th Rev. Edn (Martinus Nijhoff, Dordrecht, Netherlands, 1986).

P. H. Geil, “Polymer Single Crystals” (Interscience, New York, 1963).

W. Y. Yeh and S. L. Lambert, Macromol. Sci. Phys. B6 (1972) 599.

S. Kumar, D. P. Anderson and W. W. Adams, Polymer 27 (1986) 329.

A. J. Waddon, M. J. Hill, A. Keller and D. J. Blundell, J. Mater. Sci. 22 (1985) 1773.

Heike Motz, PhD Thesis, University of Delaware (1988).

D. C. Bassett, “Principles of Polymer Morphology” (Cambridge University Press, Cambridge, 1981).

J. M. Schultz, “Polymer Materials Science” (Prentice-Hall, New Jersey, 1974).

J. M. S. Hearle, “Polymers and Their Properties, Vol. 1, Fundamentals of Structure and Mechanics” (Ellis Horwood Publishers, England, 1982).

F. Lednicky, Proceedings 17th Europhysics Conference on Macromolecular Physics, (Walter de Gruyter, New York, 1986) p. 54.

F. Lednicky and Z. Pelzbauer, J. Polym. Sci. Part C 38 (1972) 375.

K. Friedrich, Personal Communication, University of Delaware (1988).

J. Karger-Kocsis and K. Friedrich, Polymer 27 (1986) 1753.

Idem., Plast. Rubber Proc. 8 (1987) 91.

K. Friedrich, R. Walter, H. Voss and J. Karger-Kocsis, Composites 17 (1986) 205.

W. S. Dubner, Personal Communication, University of Delaware (1988).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chu, JN., Schultz, J.M. The influence of microstructure on the failure behaviour of PEEK. J Mater Sci 24, 4538–4544 (1989). https://doi.org/10.1007/BF00544542

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00544542