Abstract

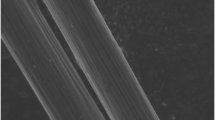

Type I PAN-based carbon fibres have been stressed to failure in glycerol; this enables the fracture ends to be preserved intact for subsequent examination, first by scanning electron microscopy, then, after embedding and sectioning, by transmission electron microscopy. Internal flaws which did not initiate failure was seen to have walls containing crystallites arranged mainly parallel to the fibre axis. Internal and surface flaws which did initiate failure showed evidence of large misoriented crystallites in the walls of the flaws. It is the presence of misoriented crystallites rather than the flaw itself which determines whether or not tensile failure will occur. Our observations are entirely consistent with the Reynolds-Sharp mechanism of tensile failure in which the concentration of shear energy in a misoriented crystallite is not relieved by cracks parallel to the layer planes but by cracks at right angles. It is possible to predict that, in the absence of gross flaws, breaking strains of 1 to 1.3% should be possible in Type I PANbased carbon fibres, and greater than 2% in Type II carbon fibres.

Similar content being viewed by others

References

A. Fourdeux, R. Perret and W. Ruland, “Carbon Fibres: Their Composites and Applications” (Plastics Institute, London, 1971) p. 57.

R. Moreton, Fibre Sci. Technol. 1 (1968) 273.

J. W. Johnson, Appl. Polym. Symp. 9 (1969) 229.

J. W. Johnson and D. J. Thorrne, Carbon 7 (1969) 659.

J. V. Sharp and S. G. Burnay, “Carbon Fibres: Their Composites and Applications” (Plastics Institute, London, 1971) p. 68.

W. N. Reynolds, Chem. Phys. Carbon 11 (1973) 1.

R. Moreton and W. Watt, Nature 247 (1974) 360.

N. H. Macmillan, J. Mater. Sci. 7 (1972) 239.

G. Dorey, Phys. Technol. 11 (1980) 56.

D. J. Johnson, “Carbon Fibres: Their Composites and Applications” (Plastics Institute, London, 1971) p. 52.

D. Crawford and D. J. Johnson, J. Microsc. 94 (1971) 51.

D. J. Johnson, D. Crawford and B. F. Jones, J. Mater. Sci. 8 (1973) 286.

S. C. Bennett and D. J. Johnson, Carbon 17 (1979) 25.

D. J. Johnson, Phil. Trans. Roy. Soc. Lond. A294 (1980) 443.

S. C. Bennett and D. J. Johnson, “Fifth London International Carbon and Graphite Conference” (Society of Chemical Industry, London, 1978) p. 377.

S. C. Bennett, D. J. Johnson and R. Murray, Carbon 14 (1976) 117.

W. N. Reynolds and J. V. Sharp, Carbon 12 (1974) 103.

S. Chwastiak, J. B. Barr and R. Didchenko, ibid. 17 (1979) 49.

W. Johnson, “Third London International Carbon and Graphite Conference” (Society of Chemical Industry, London, 1970) p. 447.

J. B. Jones, J. B. Barr and R. E. Smith, J. Mater. Sci. 15 (1980) 2455.

C. B. Beetz Jr, Fibre Sci. Technol. 16 (1982) 45.

Idem, ibid. 16 (1982) 81.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Bennett, S.C., Johnson, D.J. & Johnson, W. Strength-structure relationships in PAN-based carbon fibres. J Mater Sci 18, 3337–3347 (1983). https://doi.org/10.1007/BF00544159

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00544159