Summary

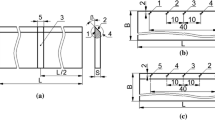

A study was made of relationships between wear (loss of metal) and blunting (reduced performance) of the corner of a steel cutting tool turning a work-piece of hard fibreboard. Rake angle, clearance angle and surface preparation (grinding, polishing) were varied and measurements made were the three cutting force components and various wear parameters. It was confirmed that retraction of the edge from its initial position is not a satisfactory index of blunting and that the shape parameter corresponding to compression of the cut surface (negative clearance) was most influential. Also, for the particular tool and work-piece materials used and in the practical range of bluntness, the ratio of negative clearance to the width of the back wear land, as measured parallel to the cutting plane, was roughly constant. It is evident that development of a hard, very thin layer on the back face would minimize negative clearance and extend sharpening life. In the practical range for cutting wood and wood-based materials, clearance angle had a relatively small effect on the rate at which negative clearance and cutting forces increased, and rake angle had negligible effects. It is concluded that these angles should not be increased without taking into account factors other than blunting. Polishing considerably decreased blunting rate, especially of the tool corner, which is especially important in sawing. The expense of polishing may be justified in some exacting operations.

Similar content being viewed by others

References

Chardin, A.; Froidure, J. 1970. A study of the wear of saw-teeth. Vol. I, Centre Technique Forestier Tropical, France

Cowling, R. L.; McKenzie, W. M. 1969. Lapping of steel tools for maximum sharpness. Wood Science 2 (1): 20–25

Englesson, T. 1953. The grinding technique and its importance for the economy of the use of high grade cutting tools in the wood working industry. Paperi Puu 35 (11): 437–448. CSIRO Transl. No. 2407

King, B. Foschi, R. O. 1969. Crosses-ring dynamometer for direct force resolution into three orthogonal components. Intern. J. Machine Tool Design and Research 9: 345–356

McKenzie, W. M.; Franz, N. C. 1964. Basic aspects of inclined or oblique wood cutting. Forest Prod. J. 14 (12): 555–566

McKenzie, W. M.; cowling, R. L. 1970. The early stage of edge wear in cutting wood. Svenska Träforskningsinstitutet. Meddelande B (74): 39–45

McKenzie, W. M.; Cowling, R. L. 1971. A factorial experiment in transverse-plane (90/90) cutting of wood. Part I. Cutting force and edge wear. Wood Science 3 (4): 204–213

Pahlitzsch, G.; Sandvoss, E. 1970. Analysis of edge bluntness in the milling of hardboards. Svenska Träforskningsinstitutet. Meddelande B (74): 5–38

Pahlitzsch, G.; Sandvoss, E. 1972. Effect of the cutting conditions on loading and wear of the cutting wedge. Holz Roh Werkstoff 30 (30): 133–143

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

McKenzie, W.M., Karpovich, H. Wear and blunting of the tool corner in cutting a wood-based material. Wood Science and Technology 9, 59–73 (1975). https://doi.org/10.1007/BF00351915

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00351915