Summary

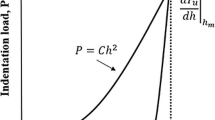

Functional coating and surface modified layers can be characterized by engineering related criteria such as the ultramicrohardness test and the scratch adhesion test. The ultramicrohardness test is based on penetration depth measurements during a loading and unloading cycle. The depth sensing indentation provides a means of evaluating the elastic and plastic deformations of the tested material, from which, by calculation, the microhardness, HV, and the elasticity modulus, E, can be derived as illustrated on a number of examples of hard and soft materials and coating composites. The scratch test (REVETESTR) and microscratch test (MSTR) has been applied to determine the adhesive and/or cohesive strength of coatings deposited on softer or tougher substrates. A Rockwell C diamond cone is used to scratch the surface of the coated or surface-modified specimen at a constant speed and under a continuously increasing load. The smallest load at which the coating is damaged, called the Critical Load, Lc, is determined by optical, electron optical, acoustic emission detection and/or by frictional force measurement, i.e. by the sudden increase of the driving force. This is illustrated on hard, brittle, and on soft coatings.

Similar content being viewed by others

References

Pollock HM, Maugis D, Barquins M (1986) Microindentation techniques in material science and engineering. ASTM STP 889, Philadelphia 47

Lebouvier D, Gilormini P, Felder E, (1985) J Phys D Appl Phys 18:199

Bulychev SI, Alekhin VP, Shorshorov MK (1976) Strength of mat 9:1084

Pethica JB, Hutchins R, Oliver WC (1983) Phil Mag A 48:593

Doerner MF, Nix WD (1986) J Mat Res 1:601

Loubet JL, Georges JM, Meille G (1986) Microindentation techniques in material science and engineering. ASTM STP 889, Philadelphia 72

Shorshorov MK, Bulychev SI, Alekthin VP (1981) Sov Phys Dokl 26:769

Sneddon IN (1965) Int J Eng Sci 3:47

Loubet JL, Georges JM, Marchesini JM, Meille G (1984) 106:43

Julia-Schmutz C, Jeanneret JP, Tranganida S, Hintermann HE (1991) Blech, Rohre, Profile 38:3

Shetty DK, Rosenfield AR, Duckworth WH (1985) J Am Ceram Soc 68:282

Lawn BR, Evans AG (1977) J Mat Sci 12:2195

Steinmann PA, Hintermann HE (1985) J Vac Sci Technol A 3:2394

Laeng P, Steinmann PA, Hintermann HE (1986) Proc ISTFA '86, Los Angeles 67

Schmutz C, Jeanneret JP, Tranganida S, Hintermann HE (1989) Proc 3rd Int Conf on Surface Modification, TMS, Neuchâtel 811

Sekler J, Steinmann PA, Hintermann HE (1988) Surface and Coatings Technology 36:519

Steinmann PA, Hintermann HE (1989) J Vac Sci Technol A 7:2267

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hintermann, H.E. Characterization of surface coatings by the scratch adhesion test and by indentation measurements. Fresenius J Anal Chem 346, 45–52 (1993). https://doi.org/10.1007/BF00321380

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00321380