Summary

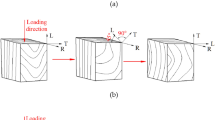

A rationale is presented for developing a mathematical model which describes a randomly packed, short-fibre-type wood composite. The model will utilize probability theory to insure random packing both in terms of flake position and orientation. Knowledge about the spatial relationship between wood elements will be used, in future, to predict a number of physical parameters associated with the composite structure. This will be accomplished by first developing a single-layer-flake model and subsequently proceeding to a multi-layer mat structure.

Similar content being viewed by others

References

Bolton, A. J.; Humphrey, P. E. 1988: The hot pressing of dry-formed wood based composites. Part 1. A review of the literature. Holzforschung 42: 403–406

Evans, K. A.; Gibson, A. G. 1986: Prediction of the maximum packing fraction achievable in randomly oriented short-fibre composites. Composite Sci. Technol. 25: 149–162

Gefahrt, J. 1977: Zur Späneerwärmung mit Hochfrequenzenergie — Modell zur Berechnung des Temperaturverlaufes in Vielsmitte bei der Heisspressung. Holz Roh-Werkstoff 35(5): 183–188

Harless, T. E.; Wagner, F. G.; Short, P. H.; Seale, R. D.; Mitchell, P. H.; Ladd, D. S. 1987: A model to predict the density profile of particleboard. Wood Fiber Sci. 19(1): 81–92

Humphrey, P. E.; Bolton, A. J. 1989: The hot pressing of dry formed based composites. Part II. A simulation model for heat and moisture transfer and typical results. Holzforschung 43(3): 199–206

Kallmes, O.; Corte, H. 1960: The structure of paper. I. The statistical geometry of an ideal two dimensional fibre network. Tappi 43(9): 737–752

Kallmes, O.; Corte, H.; Bernier, J. 1961: The structure of paper. II. The statistical geometry of multiplanar fibre network. Tappi 44(7): 519–528

Kelly, M. 1977: Critical review of relationships between processing parameters and physical properties of particleboard. General Technical Report FPL-10. pp. 1–65. U.S. Forest Products Lab: Madison, Wisconsin

Milewski, J. 1978: Packing concepts in the use of filler and reinforcement combinations. In Katz, H. S.; Milewski, J. (Ed): Handbook of fillers and reinforcements for plastics, pp. 66–77. London: Van Norstrand Reinhold

Suchsland, O. 1959: An analysis of the particleboard process. Michigan Quarterly Bulletin. 42(2): 350–372

Wolcott, M.; Kamke, F. A.; Dillard, D. A. 1990: Fundamentals of flakeboard manufacture: viscoelastic behaviour of wood components. Wood Fiber Sci. 22(4): 345–361

Author information

Authors and Affiliations

Additional information

Financial support for this work from NSERC/Canada through a strategic research grant is gratefully acknowledged

Rights and permissions

About this article

Cite this article

Steiner, P.R., Dai, C. Spatial structure of wood composites in relation to processing and performance characteristics. Wood Sci.Technol. 28, 45–51 (1993). https://doi.org/10.1007/BF00193875

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00193875