Abstract

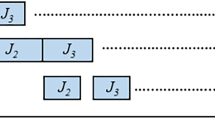

In this article we consider the problem of determining the minimum cost configuration (number of machines and pallets) for a flexible manufacturing system with the constraint of meeting a prespecified throughput, while simultaneously allocating the total workload among the machines (or groups of machines). Our procedure allows consideration of upper and lower bounds on the workload at each machine group. These bounds arise as a consequence of precedence constraints among the various operations and/or limitations on the number or combinations of operations that can be assigned to a machine because of constraints on tool slots or the space required to store assembly components. Earlier work on problems of this nature assumes that the workload allocation is given. For the single-machine-type problem we develop an efficient implicit enumeration procedure that uses fathoming rules to eliminate dominated configurations, and we present computational results. We discuss how this procedure can be used as a building block in solving the problem with multiple machine types.

Similar content being viewed by others

References

Avriel, M., Nonlinear Programming Analysis and Methods, Prentice-Hall, Inc., Englewood Cliffs, NJ (1976).

Dallery, Y. and Frein, Y., “An Efficient Method to Determine the Optimal Configuration of a Flexible Manufacturing System,” Proceedings of the 2nd ORSA/TIMS Conference on Flexible Manufacturing Systems, K.E. Stecke and R. Suri (eds.) Elsevier Science Publishers, B.V., Amsterdam, pp. 269–282 (1986).

Gordon, W.J. and Newell, G.F., “Closed Queueing Networks with Exponential Servers,” Operations Research, Vol. 15, pp. 252–267 (1967).

Kleinrock, L. Queueing Systems I and II, John Wiley and Sons, Inc., New York, NY (1976).

Lee, H.F., Srinivasan, M.M., and Yano, C.A., “Some Characteristics of Optimal Workload Allocation for Closed Queueing Networks,” Performance Evaluation, Vol. 13, No. 1 (1991).

Muntz, R.R. and Wong, J.W., “Asymptotic Properties of Closed Queueing Network Models,” Proceedings of the 8th Annual Princeton Conference on Information Sciences and Systems, Princeton University, Princeton, NJ (1974).

Saigal, R., “On the Convergence Rate of Algorithms for Solving Equations That Are Based on Methods of Complementary Pivoting,” Vol. 2, pp. 108–124 (1977).

Shanthikumar, J.G. and Yao, D.D., “Optimal Server Allocation in a System of Multi-Server Stations,” Management Science, Vol. 33, No. 9, pp. 1173–1180 (1987).

Shanthikumar, J.G. and Yao, D.D., “On Server Allocation in Multiple Center Manufacturing Systems,” Operations Research, Vol. 36, No. 2, pp. 333–342 (1988).

Solberg, J.J., “A Mathematical Model of Computerized Manufacturing Systems,” Proceedings of the 4th International Conference of Production Research, Tokyo, Japan (August 1977).

Stecke, K.E., “A Hierarchical Approach to Solving Machine Grouping and Loading Problems of Flexible Manufacturing Systems,” European Journal of Operational Research, Vol. 24, pp. 369–378 (1986).

Stecke, K.E. and Solberg, J.J. “The Optimality of Unbalancing Both Workloads and Machine Group Sizes in Closed Queueing Networks of Multi-Server Queues,” Operations Research, Vol. 33, No. 4, pp. 882–910 (1985).

Suri, R., “A Concept of Monotonicity and Its Characterization for Closed Queueing Networks,” Operations Research, Vol. 33, No. 3, pp. 606–624 (1985).

Suri, R. and Hildebrant, R.R., “Modeling Flexible Manufacturing Systems Using Mean-Value Analysis,” Journal of Manufacturing Systems, Vol. 3, No. 1, pp. 27–38 (1984).

Vinod, B. and Solberg, J.J., “The Optimal Design of Flexible Manufacturing Systems,” International Journal of Product Research, Vol. 23, No. 6, pp. 1141–1151 (1985).

Yao, D.D., “Some Properties of the Throughput Function of Closed Networks of Queues,” Operations Research Letters, Vol. 3, No. 6, pp. 313–317 (1985).

Yao, D.D. and Shanthikumar, J.G. “Some Resource Allocation Problems in Multi-Cell Systems,” Proceedings of the 2nd ORSA/TIMS Conference on Flexible Manufacturing Systems, K.E. Stecke and R. Suri (eds.) Elsevier Science Publishers, B.V., Amsterdam, pp. 245–256 (1986).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, H.F., Srinivasan, M.M. & Yano, C.A. The optimal configuration and workload allocation problem in flexible manufacturing systems. Int J Flex Manuf Syst 3, 213–230 (1991). https://doi.org/10.1007/BF00170207

Issue Date:

DOI: https://doi.org/10.1007/BF00170207