Abstract

Flexibility in part process representation and in highly adaptive routing algorithms are two major sources for improvement in the control of flexible manufacturing systems (FMSs). This article reports the investigation of the impact of these two kinds of flexibilities on the performance of the system. We argue that, when feasible, the choices of operations and sequencing of the part process plans should be deferred until detailed knowledge about the real-time factory state is available.

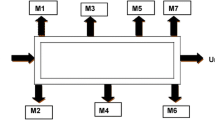

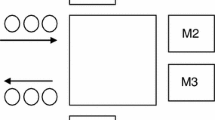

To test our ideas, a flexible routing control simulation system (FRCS) was constructed and a programming language for modeling FMS part process plans, control strategies, and environments of the FMS was designed and implemented. In addition, a scheme for implementing flexible process routing called data flow dispatching rule (DFDR) was derived.

The simulation results indicate that flexible processing can reduce mean flow time while increasing system throughput and machine utilization. We observed that this form of flexibility makes automatic load balancing of the machines possible. On the other hand, it also makes the control and scheduling process more complicated and calls for new control algorithms.

Similar content being viewed by others

References

Browne, Jim, Dubois, Didier, Rathmill, Keith, Sethi, Suresh P., and Stecke, Kathryn E., “Classification of Flexible Manufacturing Systems,” The FMS Magazine, pp. 114–117 (April 1984).

Buzacott, J.A., “Optimal Operating Rules for Automated Manufacturing Systems,” IEEE Transactions on Automatic Control, Vol. AC-27, No. 1 (February 1982).

Buzacott, J.A. and Shanthikumar, J.G., “Models for Understanding Flexible Manufacturing Systems,” AIIE Transactions, Vol. 12, pp. 339–350 (December 1980).

Chang, Y.L., Sullivan, R.S., and Bagchi, U.S., “Experimental Investigation of Real-Time Scheduling in Flexible Manufacturing Systems,” Proceedings of the First ORSA/TIMS Conference on Flexible Manufacturing Systems, K.E. Stecke and R. Suri (eds.), The University of Michigan, Ann Arbor, MI, pp. 307–312 (August 1984).

Dar-El, E.M. and Sarin, S.C., “Scheduling Parts in FMS to Achieve Maximum Machine Utilization,” Proceedings of the First ORSA/TIMS Conference on Flexible Manufacturing Systems, The University of Michigan, Ann Arbor, MI, pp. 300–306 (August 1984).

Gerwin, D., “Do's and Don'ts of Computerized Manufacturing,” Harvard Business Review, Vol. 60, No. 2, pp. 107–116 (1982).

Hancock, Terence M., “Effects of Alternate Routings under Variable Lot-Size Conditions,” International Journal of Production Research, Vol. 27, No. 2, pp. 247–259 (1989).

Hildebrandt, R.R. and Suri, R., “Methodology and Multilevel Algorithm Structure for Scheduling and Real Time Control of Flexible Manufacturing Systems,” Proceedings, 3rd International Symposium on Large Engineering Systems, Memorial University of Newfoundland, Canada (July 1983).

Kimemia, Joseph and Gershwin, Stanley B., “Network Flow Optimization in Flexible Manufacturing Systems,” Proceedings of the IEEE Conference on Decision and Control, pp. 633–639 (December 1978).

Kimemia, Joseph and Gershwin, Stanley B., “Flow Optimization in Flexible Manufacturing Systems,” International Journal of Production Research, Vol. 23, No. 1, pp. 81–96 (1985).

Lewis, W.C., Barash, M.M., and Solberg, J.J., “Computer Integrated Manufacturing System Control: A Data-Flow Approach,” Journal of Manufacturing Systems, Vol. 6, No. 3, pp. 177–191 (1987).

Lin, Yuh-Jiun and Solberg, James J., “A Flexible Control Simulation System for FMS,” Technical Report, Engineering Research Center for Intelligent Manufacturing Systems, Purdue University, West Lafayette, IN (1989).

Lin, Yuh-Jiun and Solberg, James J., “Flexible Routing Control and Scheduling,” in Proceedings of the Third ORSA/TIMS Conference on Flexible Manufacturing Systems, K.E. Stecke and R. Suri (Eds.), Elsevier Science Publishers B.V., Amsterdam, pp. 155–160 (August 1989).

Maley, James G. and Solberg, James J., “Part Flow Orchestration in CIM,” Proceedings of the International Conference on Production Research, Cincinnati, OH, pp. 17–20 (August 1987).

Maley, James G., “Managing the Flow of Intelligent Parts,” International Conference on the Manufacturing Science, Technology of the Future, MIT, Cambridge, MA (June 1987).

Parunak, H.V.D., Irish, Bruce V., Kindrick, James, and Lozo, Peter W., “Fractal Actors for Distributed Manufacturing Control,” The Second Conference on Artificial Intelligence Applications, pp. 653–660 (December 1985).

Parunak, H.V.D., “Manufacturing Experience with the Contract Net,” Technical Report ITI TR-86–36, Communications and Distributed Systems Laboratory, Industrial Technology Institute, Ann Arbor, MI (1986).

Shaw, Michael J.P., “Distributed Planning in Cellular Flexible Manufacturing Systems,” Infor, Vol. 25, No. 1, pp. 13–25 (1987).

Shaw, Michael J.P. and Whinston, Andrew B., “A Distributed Knowledge-based Approach to Flexible Automation: The Contract Net Framework,” International Journal of Flexible Manufacturing Systems, Vol. 1, No. 1 (September 1988).

Solberg, James J., “Production Planning and Scheduling in CIM,” Proceedings of the 11th World Computer Congress, IFIP, San Francisco, CA (August 1989).

Stecke, Kathryn E., “Formulation and Solution of Nonlinear Integer Production Planning Problems for Flexible Manufacturing Systems,” Management Science, Vol. 29, No. 3, pp. 273–288 (March 1983).

Stecke, Kathryn E. and Kim, Ilyong, “A Study of FMS Part Type Selection Approaches for Short-Term Production Planning,” International Journal of Flexible Manufacturing Systems, Vol. 1, No. 1, pp. 7–29 (September 1988).

Stecke, Kathryn E. and Solberg, James J., “Loading and Control Policies for a Flexible Manufacturing System,” International Journal of Production Research, Vol. 19, No. 5, pp. 481–490 (1981).

Stecke, Kathryn E. and Solberg, James J., “The Optimality of Unbalancing Both Workloads and Machine Group Sizes in Closed Queueing Networks of Multiserver Queues,” Operations Research, Vol. 33, No. 4, pp. 882–910 (July–August 1985).

Wilhelm, W.E. and Shin, Hyun-Myung, “Effectiveness of Alternate Operations in a Flexible Manufacturing System,” International Journal of Production Research, Vol. 23, No. 1, pp. 65–79 (1985).

Wittrock, R.J., “An Adaptive Scheduling Algorithm for Flexible Flow Lines,” Operations Research, Vol. 36, No. 3, pp. 445–453 (1988).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lin, G.YJ., Solberg, J.J. Effectiveness of flexible routing control. Int J Flex Manuf Syst 3, 189–211 (1991). https://doi.org/10.1007/BF00170206

Issue Date:

DOI: https://doi.org/10.1007/BF00170206