Abstract

In this paper the circumferentially-cracked cylindrical (CCC) specimen is subjected to both asymptotic and finite element analyses to determine its suitability for measuring the critical tearing energy, T c of rubber-like materials. When deformed axially, these specimens produce uniform radial crack deformation and extension along the circular crack front. The local/pointwise value of tearing energy along the crack front is also uniform and therefore identical to the tearing energy magnitude obtained by global measurement techniques such as the compliance method.

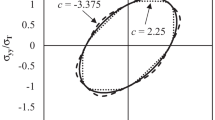

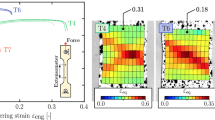

Application of the CCC specimen is illustrated on a non-crystallizing rubber (SBR). Experimental results and non-linear finite element analysis are used to show that the CCC specimen yields a constant value of T c which is statistically independent of crack depth and the two sizes of the specimen used in the experiments. The CCC specimen represents an improvement over pre-cracked thin sheet specimens used for measuring T c where it has been demonstrated (see Mazich, et al. [2]), that crack extension along the crack front is pointwise non-uniform resulting in a globally measured value for critical tearing energy that is very dependent on specimen thickness and therefore different from the purportedly invariant material parameter T c. The asymptotic analysis yields an expression relating tearing energy, T, deformed crack-tip radius, ρ0, and material shear modulus, G of the form: % MathType!MTEF!2!1!+-% feaafiart1ev1aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn% hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr% 4rNCHbGeaGak0Jf9crFfpeea0xh9v8qiW7rqqrFfpeea0xe9Lq-Jc9% vqaqpepm0xbba9pwe9Q8fs0-yqaqpepae9pg0FirpepeKkFr0xfr-x% fr-xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamivaiabg2% da9maalaaabaGaaG4maaqaaiaaiIdaaaGaeqiWdaNaam4raiabeg8a% YnaaBaaaleaacaaIWaaabeaaaaa!409C!\[T = \frac{3}{8}\pi G\rho _0 \]. This expression yields numerical results which are in excellent agreement with the finite element predictions and test data.

Similar content being viewed by others

References

R.S. Rivlin and A.G. Thomas, Journal of Polymer Science 10, No. 3 (1953) 291–318.

K.A. Mazich, K.N. Morman, F.G. Oblinger, T.Y. Pan and P.C. Killgoar, Rubber Chemistry and Technology 62 (1989) 850–862.

R.A. Stephenson, Journal of Elasticity 12 (1982) 65–99.

R.W. Ogden, Proceedings Royal Society of London, Series A326 (1972) 565–584.

L.R.G. Treloar, The Physics of Rubber Elasticity, 3rd ed., Clarendon Press, Oxford (1975).

K.N. Morman, Journal of Applied Mechanics 53 (1986) 723–726.

P. Chadwick, Journal of Elasticity 5 (1975) 249–258.

R.L. Taylor, in The Finite Element Method, O.C. Zienkiewicz, McGraw-Hill, London (1977).

J.C. Simo and R.L. Taylor, Computer Methods in Applied Mechanics and Engineering 85 (1991) 273–310.

E.H. Twizell and R.W. Ogden, Journal of the Australian Mathematical Society, Series B (1983) 424–434.

B. Moran and C.F. Shih, Engineering Fracture Mechanics 27 (1987) 615–642.

E.H. Andrews, Proceedings of the Physical Society 77 (1961) 483–498.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Morman, K.N., Mazich, K.A., Oblinger, F.G. et al. Critical tearing energy in a circumferentially-cracked circular cylinder of rubber under finite deformation. Int J Fract 53, 129–157 (1992). https://doi.org/10.1007/BF00034669

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00034669