Abstract

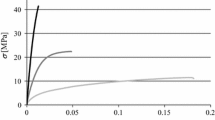

Failure mechanisms of materials under very high strain experienced at and ahead of the crack tip such as the formation, growth and interaction of microvoids in ductile materials, microcracks in brittle solids or crazes in polymers and adhesives are represented by one-dimensional, nonlinear stress-strain relations possessing different post-yield softening (strain-softening) behavior. These reflect different ways by which the material loses capacity to carry load up to fracture or total separation. A DCB type specimen is considered in this study. * The nonlinear material is confined to a thin strip between the two elastic beams loaded by a wedge. The problem is first modelled as a beam on a nonlinear foundation. The pertinent equation is solved numerically as a two-point boundary value problem for both the stationary and the quasi-statically propagating crack. A finite element model is then used to model the problem in more detail to assess the adequacy of the beam model for the use of experimental data to determine in-situ properties of the thin interlayer.

It is found that the energy release rate derived by assuming built-in conditions at the crack tip can be used to calculate the fracture (surface) energy more accurately and conveniently than Berry's scheme [2] even in cases where the built-in assumption is apparently invalid. The analyses suggest that it is possible to infer from detailed macroscopic measurements of the deformations of the beam prior to and during crack growth the approximate characteristics of the complete (uniaxial) material stress-strain behavior of the cohesive interlayer including loading and strain-softening.

Résumé

On représente les mécanismes de rupture de matériaux sous de trés fortes déformations appliquées à l'extrémité ou en amont de fissures tels que la formation, la croissance et l'interaction de micro-lacunes dans les matériaux ductiles, les micro-fissures dans les matériaux fragiles ou les craquelures dans les polymères et les adhésifs, par des relations contraintes-déformations non linéaires, unidimensionnelles et présentant des comportements différents d'adoucissement à l'écrouissage. Ces mécanismes reflètent diverses voies selon lesquelles un matériau perd sa capacité de supporter une charge avant rupture ou séparation totale. Dans cette étude, on considère une éprouvette de type double Cantilever, un matériau non élastique étant ramené à une bande mince comprise entre deux poutres élastique étant ramené à une bande mince comprise entre deux poutres élastique étant ramené à une bande mince comprise entre deux poutres élastiques sollicitées par un coin. On commence par représenter le problème comme une poutre reposant sur un support non linéaire. Par voie numérique, on résoud l'équation correspondante dans les cas d'une fissure stationnaire et d'une fissure en propagation quasi-statique. On utilise ensuite un modèle par éléments finis pour représenter avec plus de détails le problème en vue de vérifier l'adéquation du type d'éprouvette pour l'utilisation des données expérimentales à la détermination des propriétés in situ de l'intercouche mince.

On trouver que la vitesse de relaxation de l'énergie obtenue en supposant des conditions de consolidation à l'extrémité de la fissure peut être utilisée pour la calcul de l'énergie de rupture (en surface) de mainère plus précise et plus commode que l'approche de Berry, même dans les cas où une hypothèse de consolidation n'est apparemment pas valable. L'analyse suggère qu'il est possible de déduire les caractéristiques approchées du comportement complet du matériau du point de vue contraintes-dilatations (uniaxiales) relatives à l'intercouche de liaison, tant pour la mise en charge que pour l'adoucissement, à partir de mesures macroscopiques détaillées des déformations de la poutre avant et durant l'expansion de la fissure.

Similar content being viewed by others

References

T. Ungsuwarungsri, “The Effect of Strain-Softening Cohesive Material on Crack Stability”, Ph.D. thesis, Graduate Aeronautical Laboratories, California Institute of Technology, Pasadena (1986).

J.P. Berry, Journal of Applied Physics 34 (1963) 62–68.

J.P. Berry, Journal of the Mechanics and Physics of Solids 8 (1960) 194–216

Z.J. Bilek and S.J. Burns, Journal of the Mechanics and Physics of Solids 22 (1974) 85–95.

B. Steverding and S.H. Lehnigk, International Journal of Fracture 6 (1970) 223–232.

R. Burridge and J.B. Keller, SIAM Review 20 (1978) 31–61.

M.F. Kanninen, International Journal of Fracture 6 (1970) 83–92.

M.F. Kanninen, International Journal of Fracture 10 (1974) 415–430.

F.A. McClintock, Journal of Applied Mechanics 35 (1968) 363–371.

A.L. Gurson, Journal of Engineering Materials and Technology 99 (1977) 2–15.

A. Needleman, Journal of Applied Mechanics 35 (1968) 363–371.

C.A. Berg, in Inelastic Behavior of Solids, M.F. Kanninen et al. (eds.), McGraw Hill, New York (1970), 171–209.

J.R. Rice and A. Needleman, in Mechanics of Sheet Metal Forming, D.P. Koistinen and N.M. Wang (eds.), Plenum New York (1978) 237–267.

D. Krajcinovic, Journal of Applied Mechanics 50 (1983) 355–360.

J.W. Dougill, Journal of Applied Mathematics and Physics (ZAMP) 27 (1976) 423–436.

J.W. Rudnicki, Journal of Rheology 28 (1984) 759–778.

Z.P. Bazant, International Journal of Solids and Structures 16 (1980) 873–901.

H. Andersson, Journal of the Mechanics and Physics of Solids 21 (1973) 337–356.

A.P. Kfouri and K.J. Miller, Proceedings of the Institution of Mechanical Engineers (London) 190 (1976) 571–584.

G. Rydholm, B. Fredricksson and F. Nilsson, in Numerical Methods in Fracture Mechanics, A.R. Luxmoore and D.R.J. Owen (eds.), University College of Swansea, Swansea, Wales (1978) 660–672.

J.F. Malluck and W.W. King, in Numerical Methods in Fracture Mechanics, A.R. Luxmoore and D.R.J. Owen (eds.), University College of Swansea, Swansea, Wales (1978) 648–659.

J.F. Malluck and W.W. King, in Crack Arrest Methodology and Application, G.T. Hahn and M.F. Kanninen (eds.), ASTM STP 711 (1980) 38–53.

R. Hof, C.A. Rubin and G.T. Hahn, Engineering Fracture Mechanics 23 (1986) 105–118.

H.B. Keller, Numerical Solution of Two Point Boundary Value Problems, Series: Regional Conference in Applied Mathematics, SIAM 24 (1976).

W.K. Asbeck, in Adhesion and Cohesion, P. Weiss (ed.), Elsevier Publishing, Amsterdam (1962) 101–102.

B.M. Malyshev and R.L. Salganik, International Journal of Fracture 1 (1965) 114–128.

H. Chai, “The Growth of Impact Damage in Compressively Loaded Laminates”, Ph.D. thesis, Graduate Aeronautical Laboratories, California Institute of Technology, Pasadena (1982) 102–126.

Author information

Authors and Affiliations

Additional information

This paper is a shortened version of part of [1].

An experimental program is being conducted in our laboratories to study the strain-strain characteristics of a number of polymeric solids using the DCB model discussed in this paper.

An experimental program is being conducted in our laboratories to study the strain-strain characteristics of a number of polymeric solids using the DCB model discussed in this paper.

Rights and permissions

About this article

Cite this article

Ungsuwarungsri, T., Knauss, W. The role of damage-softened material behavior in the fracture of composites and adhesives. Int J Fract 35, 221–241 (1987). https://doi.org/10.1007/BF00015590

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00015590