Abstract

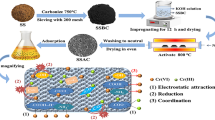

Sarawak is one of the world’s largest exporter of sago flour, from which the processing leads to a generation of biowaste in a significant amount. Thus, utilization of the biowaste is crucial to create a zero-waste sago processing industry. In this work, the heavy metal adsorbent was prepared from sago activated sludge via microwave technology. Sago effluent was treated via an activated sludge process to produce biomass, followed by microwave pyrolysis and chemical activation using NaOH. The efficiency of the adsorbent for adsorption of Cr, Pb and Zn in aqueous solution was studied at pH 2, contact time (24 h), adsorbent dosage (0.2–1 g/50 mL), and initial concentration (5–25 mg/L). Physicochemical analyses showed that the adsorbent has an average pore size of 36.29 µm and BET surface area of 471.1 m2/g. The maximum removal of heavy metals was: Pb (89.8%), Cr (47.0%) and Zn (18.4%) at adsorbent dosage (1 g/50 mL), initial concentration (5 mg/L), mixing speed (150 rpm) and contact time (24 h). The Langmuir and Freundlich isotherm studies showed that Qe for Pb removal by sludge activated carbon was 3.202 × 10–3 mg/g. The results indicated the potential application of sago activated carbon for the removal of heavy metals, especially Pb from wastewater. Further isotherm study for the occurrence of chemisorptions process could be beneficial, which at the same creating a zero-waste sago processing industry for sustainable technology.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Wahi R, Zuhaidi NFQ, Yusof Y, Jamel J, Kanakaraju D, Ngaini Z (2017) Chemically treated microwave-derived biochar: an overview. Biomass Bioenergy 107:411–421. https://doi.org/10.1016/j.biombioe.2017.08.007

Rajan Y, Ngaini Z, Wahi R (2019) Novel adsorbent from sago-grafted silica for removal of methylene blue. Int J Environ Sci Technol 16(8):4531–4542. https://doi.org/10.1007/s13762-017-1389-9

Ngaini Z, Noh F, Wahi R (2014) Esterified sago waste for engine oil removal in aqueous environment. Environ Technol 35(22):2761–2766. https://doi.org/10.1080/09593330.2014.920051

Ngaini Z, Wahi R, Abang Kamaluddin DH, Mohd Yusoff NA (2014) Modified sago waste for oil adsorption. Pertanika J Sci Technol 22(1):153–161

Wahi R, Chuah AL, Nourouzi MM, Ngaini Z, Choong-Shean-Yaw T (2017) Utilization of esterified sago bark fibre waste for removal of oil from palm oil mill effluent. Int J Chem Eng 5(1):170–177. https://doi.org/10.1016/j.jece.2016.11.038

Ngaini Z, Azlin ARKA, Nazlina S, Hasnain H, Norhaizat S, Teng JX, Lawai V (2013) Production of fire-retardant sound-absorbing panels from sago waste. J Trop For Sci 25(4):510–515

Ngaini Z, Noh F, Wahi R (2018) Facile sorbent from esterified cellulosic sago waste for engine oil removal in marine environment. Int J Environ Sci Technol 15(2):341–348. https://doi.org/10.1007/s13762-017-1389-9

Banu JR, Kaliappan S, Dieter B (2006) Treatment of sago wastewater using hybrid anaerobic reactor. Water Qual Res J Can 41:56–62. https://doi.org/10.1007/BF03326295

Abd Rashid W, Musa H, Wong SK, Bujang K (2010) The potential of extended aeration system for sago effluent treatment. Am J Appl Sci 7:616–619

Ayyasamy PM, Banuregha R, Vivekanandhan G, Rajakumar S, Yasodha R, Lee S, Lakshmanaperumalsamy P (2008) Bioremediation of sago industry effluent and its impact on seed germination (green gram and maize). World J Microb Biot 24:2677–2684. https://doi.org/10.1007/s11274-008-9796-1

Gerardi MH (2006) Wastewater bacteria. Wiley-Interscience, Hoboken, New Jersey

Lehmann J, Joseph S (2009) Biochar for environmental management: Science and technology. Earthscan Ltd., London

Demirbas A, Arin G (2002) An overview of biomass pyrolysis. Energy Sources 24:411–482. https://doi.org/10.1080/00908310252889979

Miura M, Kaga H, Sakurai A, Kakuchi T, Takahashi K (2004) Rapid pyrolysis of wood block by microwave heating. J Anal Appl Pyrol 71:187–199. https://doi.org/10.1016/S0165-2370(03)00087-1

Wahi R, Senghie H (2007) The use of microwave derived activated carbon for removal of heavy metal in aqueous solution. J Sci Tech 17:97–108

Wahi R, Ngaini Z, Jok VU (2009) Removal of mercury, lead and copper from aqueous solution by activated carbon of palm oil empty fruit bunch. World Appl Sci J 5:84–91

Gerardi MH (2002) Nitrification and denitrification in the activated sludge process. Wiley-Interscience, New York

Makshut NA, Ngaini Z, Wahi W, Hussain H, Mahmut NI, Bahrin NQ (2020) Nano-sized absorbent from pyrolysed sago activated sludge for removal of Pb (II) from aqueous solution. Pertanika J Sci Technol 28(3):893–916

Pechyen C, Atong D, Aht-Ong D, Viboon S (2007) Investigation of pyrolyzed chars from physic nut waste for the preparation of activated carbon. J Solid Mech 1498–1507.https://doi.org/10.1299/jmmp.1.498

Rao MM, Rao GPC, Seshaiah K, Choudary NV, Wang MC (2008) Activated carbon from Ceiba pentandra hulls, an agricultural waste, as an adsorbent in the removal of lead and zinc from aqueous solutions. J Waste Manag 28:849–858. https://doi.org/10.1016/j.wasman.2007.01.017

Malik R, Ramteke DS, Wate SR (2007) Adsorption of malachite green on groundnut shell waste based powdered activated carbon. J Waste Manag 27:1129–1138. https://doi.org/10.1016/j.wasman.2006.06.009

Salam OEA, Reiad NA, Elshafei MM (2011) A study of the removal characteristics of heavy metals from wastewater by low-cost adsorbents. J Adv Res 2:297–303. https://doi.org/10.1016/j.jare.2011.01.008

Qian Q, Machida M, Tatsumoto H (2007) Textural and surface chemical characteristics of activated carbons prepared from cattle manure compost. J Waste Manag 98(2):353–360. https://doi.org/10.1016/j.wasman.2007.03.029

Acknowledgements

This work was funded by Universiti Malaysia Sarawak Tun Openg Sago Research Chair (F07/TOC/1742/2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ngaini, Z., Wahi, R., Hussain, H., Bahrin, N.Q., Hasana, N.H. (2021). Heavy Metal Adsorbent of Carbon from Sago Liquid Biowaste for Sustainable Technology. In: Zaini, M.A.A., Jusoh, M., Othman, N. (eds) Proceedings of the 3rd International Conference on Separation Technology. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0742-4_14

Download citation

DOI: https://doi.org/10.1007/978-981-16-0742-4_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0741-7

Online ISBN: 978-981-16-0742-4

eBook Packages: EngineeringEngineering (R0)