Abstract

Porous silicon with its spongious structure and vast surface enlargement was investigated as the carrier matrix for immobilised enzymes in micro enzyme reactors.

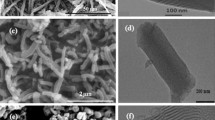

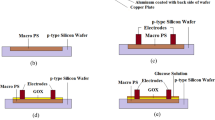

The microreactors were micromachined, in (110) silicon (p-type, 20–70 Ω.cm) by anisotropic wet etching, giving a parallel trench structure comprising 32 channels, 50 µm wide, spaced 50 µm apart and 250 µm deep. The surface enlarging porous layer on the reactor structures were achieved by anodising the reactors in a solution of hydrofluoric acid and ethanol. In order to evaluate the surface enlarging effect of different pore morphologies, the anodisation was performed at three different current densities, 10, 50 and 100 mA.cm−2.

Glucose oxidase was coupled to the surface of the porous microreactors and a non porous reference reactor. The enzyme activity of the microreactors was recorded and compared with the non-porous reference reactor.

Long-term stability measurements of glucose oxidase coupled to a planar porous silicon surface were performed. The porous layer was achieved on a (111) silicon sample; epilayer, n on n+ (6.8–9.2 Ω cm on 0.0015 Ω cm), anodised at 100 mA.cmℒ2 for 5 minutes.

The studies of the glucose turn-over rate in the different micro reactors clearly demonstrated the surface enlarging effect of porous silicon as an enzyme carrier matrix. An increase in enzyme activity by a factor of 100, compared to the non porous reference, was recorded for the reactor anodised at 50 mA.cm−2. The results also establish the possibility to fabricate porous silicon on high aspect ratio microstructures.

The long-term stability measurements displayed a high storage stability of the porous silicon carrier matrix, 2% loss after 5 months refrigerated storage. Steady state glucose loading (0.5 mM) of the GOD activated porous matrix showed a loss in enzyme activity of 56% over 4 days.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Bell T E, Gennissen P T J., DeMunter D, Kühl M, Porous silicon as a sacrificial material, Journal of Micromechanincs and Microengineering, 6 (1996), 361–369.

Lithovechenko V G, Evtukh A A, Marchenko, Klyui N I, Semenovich V A, The enhanced field from microtips covered by ultrathin layers, Journal of Micromechanincs and Microengineering, 7 (1997), 1–6.

Thust M, Schöning M J, Frohnhoff S, Arens-Fischer R, Kordos P, Lüth H, Porous silicon as a substrate material for Potentiometrie biosensor, Measurement Science and Technology, 7 (1996), 27–29.

Smith R L, An Integrated Sensor for Electrochemical Measurements, IEEE Transactions on Biomedical Engineering, BME-33 (1986), 83–90

Laurell T, Drott J, Rosengren L, Lindstrom K, Enhanced enzyme activy in silicon integrated enzyme reactor utilizing porous silicon as the coupling matrix, Sensors and Actuators B 31 (1996), 161–166.

Laurell T, Drott J, Rosengren L, Microreactors in silicon for biochemical monitoring. In: Microsystem Technology for Chemcial and Biological Microreactors (ed. W. Ehrlfed); Dechema Monograph series, 132 (1995), 139–161.

Drott J, Lindstrom K, Rosengren L, Laurell T, Porous silicon as carrier matrix in microstructured enzyme reactors yielding high enzyme activities. Journal of Micromechanincs and Microengineering, 7 (1997), 14–23.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1998 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Drott, J., Lindström, K., Rosengren, L., Laurell, T. (1998). Porous Silicon as the Carrier Martix in a Micro Enzyme Reactor to Achieve a Highly Efficient and Long-Term Stable Glucose Sensor. In: Ehrfeld, W. (eds) Microreaction Technology. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-72076-5_20

Download citation

DOI: https://doi.org/10.1007/978-3-642-72076-5_20

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-72078-9

Online ISBN: 978-3-642-72076-5

eBook Packages: Springer Book Archive