Abstract

The present work proposes a new fracture mechanical testing concept for determination of dynamic crack propagation of rubber materials. This concept implements a method of simultaneous tensile- and pure-shear-mode testing. The present approach is based on an upgrade of the Tear Analyzer (Co. Coesfeld GmbH & Co. KG), on the fracture mechanics theory of dynamically loaded test specimens and on the definition of pure-shear states according to the test specimen’s geometry ratio.

The main focus of this work can be divided into three parts. Firstly, it introduces the development of a method for analysis of dynamic crack propagation in filled rubber by simultaneous tensile- and pure shear mode testing. The servo-hydraulic machine with controlled temperature testing chamber is equipped with simultaneously operating two-mode test equipment that represents a new fracture testing method. This two-mode test allows the measurement of crack propagation on different rubber specimens simultaneously and under identical load. The data analysis allows a comparison between the two parallel running testing modes.

Secondly, this work deals with the development of a method for the defined creation of a notch in a rubber specimen. This method serves as a basis for the reproducible and reliable determination of fracture mechanical parameters for elastomers. After insertion of notches in a defined way, fracture tests under different loading conditions were performed. A significant influence on the notch geometry was observed in the test results. The results illustrated the importance of a defined and reproducible notching of elastomeric specimens.

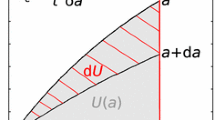

Next, the analysis of crack propagation under dynamic loading conditions is practiced with this method. It is shown how the tearing energy and the crack growth rate depend on the test specimen’s geometry ratio and crack length. It is also demonstrated that the values for tearing energies and crack growth rates for short crack lengths in SENT, as well as in pure-shear test specimens, are identical. Another important aspect of the results is related to the different values of tearing energies and crack growth rates for cracks with short and large lengths in pureshear test specimens. The results show the dependence of fracture behavior on the manufacture of the test specimens.

The new fracture mechanical testing concept offers a comparison between fracture behaviors of rubber materials independent of the test specimen’s geometry.

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Rivlin, R.S., Thomas, A.G.: Rupture of rubber. I. Characteristic energy for tearing. Journal of Polymer Science 10, 291–318 (1953)

Lake, G.J., Lindley, P.B.: Cut Growth and Fatigue of Rubbers, II. Experiments on a Noncrystallizing Rubber. Journal of Applied Polymer Science 8, 707–721 (1964)

Lake, G.J., Lindley, P.B.: The Mechanical Fatigue Limit for Rubber. Journal of Applied Polymer Science 9, 1233–1251 (1965)

Stoček, R., Heinrich, G., Gehde, M., Rauschenbach, A.: Untersuchungen zur Kerbtiefe im Pure-shear Prüfkörper für präzise Analysen der dynamischen Rissausbreitung in Elastomeren. Zeitschrift Kunststofftechnik / Journal of Plastics Technology, 2–22 (January 2012)

Yeoh, O.H.: Analysis of deformation and fracture of ‘pure shear’ rubber testpiece. Plastics, Rubber and Composites 30, 391–397 (2001)

Griffith, A.A.: The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. Lond., Ser. A 221, 163 (1920)

Lake, G.J.: Fatigue and Fracture of Elastomers. Rubber Chemistry and Technology 68, 435–460 (1995)

Klüppel, M., Huang, G., Bandow, B.: Evaluation of Tearing Energy of Elastomer Materials. Kautschuk-Gummi-Kunststoffe 61, 656–659 (2008)

Gent, A.N.: Engineering with Rubber, 2nd edn. Hanser Publishers, Munich (2001)

Gent, A.N., Lindley, P.B., Thomas, A.G.: Cut Growth and Fatigue of Rubbers. I. The Relationship between Cut Growth and Fatigue. Journal of Applied Polymer Science, 455–466 (1964)

Paris, P., Erdogan, F.: A critical analysis of crack propagation laws. Journal of Basic Engineering, Transactions of the American Society of Mechanical Engineers, 528–534 (1963)

Stoček, R., Gehde, M., Heinrich, G.: Analyse des dynamischen Risswachstums von Elastomeren im simultanen Zug-(Tensile-) und Pure-Shear-Prüfmodus bei optimierter Risserfassung. Kautschuk-Gummi-Kunststoffe 62, 170–176 (2009)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Stoček, R., Heinrich, G., Gehde, M., Kipscholl, R. (2013). Analysis of Dynamic Crack Propagation in Elastomers by Simultaneous Tensile- and Pure-Shear-Mode Testing. In: Grellmann, W., Heinrich, G., Kaliske, M., Klüppel, M., Schneider, K., Vilgis, T. (eds) Fracture Mechanics and Statistical Mechanics of Reinforced Elastomeric Blends. Lecture Notes in Applied and Computational Mechanics, vol 70. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-37910-9_7

Download citation

DOI: https://doi.org/10.1007/978-3-642-37910-9_7

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-37909-3

Online ISBN: 978-3-642-37910-9

eBook Packages: EngineeringEngineering (R0)