Abstract

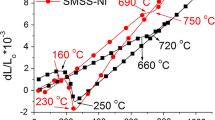

The hot cracking behaviour of extra high-purity stainless steels was investigated with respect to type 310 stainless steel with various amounts of minor and impurity elements such as C, P, S and Mn. The purity of the type 310 stainless steels used was enhanced in the order of Type 310<Type 310S<Type 310ULC<Type 310EHP steels. The hot cracking susceptibility was evaluated by the transverse-Varestraint test. This test revealed that two types of hot cracks occurred in these steels; solidification and ductility-dip cracks. The solidification cracking susceptibility was significantly reduced as the amount of C, P and S decreased, and that Type 310EHP steel reached a level so low that solidification cracking did not occur in practical welding. On the other hand, the ductility-dip cracking susceptibility adversely increased as the purity of the steels was enhanced. However, the ductility-dip cracking susceptibility of Type 310EHP steel was sufficiently as low as not to yield ductility-dip cracking in practical welding. Numerical analysis suggested that the reduced solidification cracking susceptibility upon refining C, P and S could be attributed to the reduced solidification brittle temperature range due to the suppression of solidification segregation of minor and impurity elements. The quantitative contribution of minor and impurity elements to the hot cracking susceptibility of extra high-purity type 310 stainless steels was evaluated by using lab-melted steels with different amounts of C, P, S and Mn. The essential influence on solidification cracking was the ratio of P:S:C=1:1.3:0.5, while Mn negligibly ameliorated solidification cracking in the extra low S (and P) steels. On the other hand, a molecular orbital analysis to estimate the binding strength of the grain boundary suggested that the increased ductility-dip cracking susceptibility in extra high-purity steels was caused by grain boundary embrittlement due to the refining of beneficial elements for grain boundary strengthening such as C.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Inazumi T, Hyakubu T, Takagi Y, Okimoto S, Ehira Y and Ohashi M (1993) “Development of Highly Corrosion Resistant R-SUS304ULC for Nuclear Fuel Reprocessing Plant”, NKK Technical Report, No.144, p. 20–25 (in Japanese).

Kiuchi K (2006) “Development of Equipment Materials for Purex Reprocessing Process”. Journal of Atomic Energy Society Japan 48(11):871–876 (in Japanese).

Kunii K, Kusamichi T, Nakayama J and Kiuchi K (2007) JP Patent, No.2007-154214 (in Japanese).

Shankar V, Gill TPS, Mannan SL and Sundaresan S (1988) “Fusion Zone and Heat Affected Zone Cracking Susceptibility of Stabilised Austenitic Stainless Steels”. Science and Technology Welding and Joining 3(1):17–24.

Radhakrishnan VM (2000) “Hot Cracking in Austenitic Stainless Steel Weld Metals”. Science and Technology Welding and Joining 5(1):40–44.

Lienert TJ and Lippold JC (2003) “Improved Weldability Diagram for Pulsed Laser Welded Austenitic Stainless Steels”. Science and Technology Welding & Joining 8(1):1–9.

Lundin CD, Chou CPD and Sullivan CJ (1980) “Hot Cracking Resistance of Austenitic Stainless Steel Weld Metals. Welding Journal 59(8):226s–232s.

Lippold JC and Savage WF (1982) “Solidification of Austenitic Stainless Steel Weldments: Part III, -The Effect of Solidification Behavior on Hot Cracking Susceptibility”. Welding Journal 61(12):388s–396s.

Brooks JA and Lambert FJ Jr. (1978) “The Effect of Phosphorus, Sulfur and Ferrite Content on Weld Cracking of Type 309 Stainless Steel”. Welding Journal 57(5):139s–143s.

Matsuda F, Nakagawa H, Katayama S and Arata Y (1982) “Weld Metal Cracking and Improvement of 25%Cr-20%Ni (AISI310S) Fully Austenitic Stainless Steel”, Trans. J.W.S. 13(2):115–132.

Ogawa T and Tsunetomi E (1982) “Hot Cracking Susceptibility of Austenitic Stainless Steels”. Welding Journal 61(3):82s–93s.

Kujanpää VP, David SA and White CL (1986) “Formation of Hot Cracks in Austenitic Stainless Steel Welds – Solidification Cracking”. Welding Journal 65(8):203s–212s.

Kujanpää VP (1985) “Effect of Steel Type and Impurities in Solidification Cracking of Austenitic Stainless Steel Welds”. Metal Construction 17(1):40R–46R.

Gooch TG and Honeycombe J (1980) “Welding Variables and Microfissuring in Austenitic Stainless Steel Weld Metal”. Welding Journal 59(8):233s–241s.

Rabensteiner G, Tosch J and Schabereiter H (1983) “Hot Cracking Problems in Different Fully Austenitic Weld Metals”. Welding Journal 62(1):21s–27s.

Katayama S (1981) “Improvement in Solidification Cracking of Fully Austenitic Stainless Steels SUS310S”, Doctoral Thesis, Osaka University (in Japanese).

Li L and Messler RW Jr. (1999) “The Effect of Phosphorus and Sulfur on Susceptibility to Weld Hot Cracking in Austenitic Stainless Steels”. Welding Journal 78(12):387s–396s.

Li L and Messler RW Jr. (2002) “Segregation of Phosphorus and Sulfur in Heat-Affected Zone Hot Cracking of Type 308 Stainless Steel”. Welding Journal 81(5):78s–84s.

Nishimoto K, Saida K, Okauchi H and Ohta K (2006) “Prevention of Microcracking in Reheated Weld Metal by La Addition to Filler Metal, – Microcracking in Multipass Weld Metal of Alloy 690 (Part 3) –”. Science and Technology of Welding and Joining 11(4):471–479.

Nishimoto K, Mori H and Hirata H “Effect of Grain Boundary Segregation of Sulphur on Reheat Cracking Susceptibility in Multipass Weld Metal of Fe-36%Ni Alloy”. Proceedings of the 7th International Symposium. J.W.S., Kobe (2001), pp. 827–838.

Nishimoto K, Mori H, Esaki K, Hongoh S and Shirai M (1999) “Effect of Sulphur and Thermal Cycles on Reheat Cracking Susceptibility in Multipass Weld Metal of Fe-36%Ni Alloy”, IIW Doc. IX-1934-99.

Aziz MJ (1982) “Model for Solute Redistribution during Rapid Solidification”. Journal of Applied Physics 53:1158–1168.

Morita Z and Tanaka T (1988) “Thermodynamics on the Equilibrium Distribution Coefficients of Solute Elements between Solid and Liquid Phases in Iron Alloys”. Tetsu-to-Hagane 74(7):1210–1218 (in Japanese).

The Japan Institute of Metals (2004) Kinzoku Data Book, Maruzen (in Japanese).

Adachi H, Owada H, Tanaka I, Nakamatsu H and Mizuno M (1998) Introduction to Molecular Orbital Calculation DV-Xα method, Sankyo (in Japanese).

Noecker II FF and DuPont JN (2009) “Metallurgical Investigation into Ductility Dip Cracking in Ni-Based Alloys: Part II”. Welding Journal 88(3):62s–77s.

Lippold JC and Nissley NE (2007) “Further Investigations of Ductility-Dip Cracking in High Chromium, Ni-Base Filler Metals”. Welding in the World 51(9/10):24–30.

Young GA, Capobianco TE, Penik MA, Morris BW and McGee JJ (2008) “The Mechanism of Ductility Dip Cracking in Nickel-Chromium Alloys”. Welding Journal 87(2):31s–43s.

Acknowledgements

The present study includes the results of work performed under the grant “Research and Development of Nitric Acid Resistant Material Technology Applicable to the Next Generation of Reprocessing Equipment” entrusted to Kobe Steel, Ltd. by the Ministry of Education, Culture, Sports, Science and Technology of Japan (MEXT).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Nishimoto, K., Saida, K., Kiuchi, K., Nakayama, J. (2011). Influence of Minor and Impurity Elements on Hot Cracking Susceptibility of Extra High-Purity Type 310 Stainless Steels. In: Böllinghaus, T., Lippold, J., Cross, C. (eds) Hot Cracking Phenomena in Welds III. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-16864-2_11

Download citation

DOI: https://doi.org/10.1007/978-3-642-16864-2_11

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-16863-5

Online ISBN: 978-3-642-16864-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)