Abstract

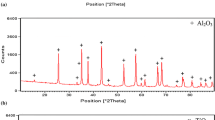

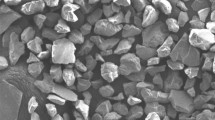

Erosion-wear properties of 45PS, SL30 and FeAl/Cr3C2 coatings sprayed by high velocity arc spraying (HVAS) at different temperature and impact angle were investigated using an air solid particle erosion rig. Erosion-wear mechanisms were also investigated by means of scanning electronic microscopy (SEM), energy-dispersive analysis X-ray spectroscopy (EDAX) and X-Ray diffraction (XRD), respectively. Results show that the erosion-wear rate decreases with the increase of temperature for all of the three coatings. The variation of the erosion-wear rate with the impact angle is different for different coating. The erosion-wear mechanisms under different conditions are different also.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Habib, M.A., Badr, H.M., Ben-Mansour, R. M., Kabir, E., 2007, “Erosion rate correlations of a pipe protruded in an abrupt pipe contraction,” International Journal of Impact Engineering, 34, pp.1350–1369.

Kulu, P., Hussainova, I., Veinthal, R., 2005, “Solid particle erosion of thermal sprayed coatings,” Wear, 258, pp.488–496.

Huttunen-Saarivirta, E., Stott, F.H., Rohr, V., Schütze M., 2007, “Erosion-oxidation behaviour of pack-aluminized 9% chromium steel under fluidized-bed conditions at elevated temperature,” Corrosion Science, 49, pp.2844–2865.

Hocking, M.G., Vasantasree, V., Sidky, P.S., 1989, Metallic and Ceramic Coatings: Production, High Temperature Properties and Applications, Longman Scientific and Technical Press, UK.

Matthews S., Hyland M., James B., 2003, “Microhardness variation in relation to carbide development in heat treated Cr3C2-NiCr thermal spray coatings,” Acta Materialia, 51 (14), pp.4267–4277.

Takeuchi J., Murata Y., Harada Y., et al., 1998, in: C. Coddet (Ed.), Thermal Spray: Meeting the Challenges of the 21st Century, ASM International, Materials Park, OH, USA, 1998, pp.1425–1430.

Kim D.Y., Han M.S., Youn J. G., 1996, in: C.C. Berndt (Ed.), Thermal Spray: Practical Solutions for Engineering Problems, ASM International, Materials Park, OH, USA, 1996, pp.123–128.

Seong B.G., Hwang S.Y., Kim K.Y., 2000, “Hightemperature corrosion of recuperators used in steel mills,” Surface and Coatings Technology, 126 (2–3), pp.256–265.

Mann B.S., Prakash B., 2000, “High temperature friction and wear characteristics of various coating materials for steam valve spindle application,” Wear, 240 (1–2), pp.223–230.

Qureshi, J., Tabakoff, W., 1988, “The influence of coating processes and process parameters on surface erosion resistance and substrate fatigue strength,” Surface and Coatings Technology, 36, pp.433–444.

Lin, F., Shao, H., 1991, “The effect of impingement angle on slurry erosion,” Wear, 141, pp.279–289.

Franco, A., Roberts, S.G., 1998, “The effect of impact angle on the erosion rate of polycrystalline α-Al2O3,” Journal of European Ceramic Society, 18, pp.269–274.

Newbery, A.P., Rayment, T., Grant, P.S., 2004, “A particle image velocimetry investigation of in-flight and deposition behaviour of steel droplets during electric arc sprayforming,” Materials Science and Engineering A, 383, pp.137–145.

Planche, M.P., Liao, H., Coddet, C., 2004, “Relationships between in-flight particle characteristics and coating microstructure with a twin wire arc spray process and different working conditions,” Surface and Coatings Technology, 182, pp.215–226.

Liu, G.M., Rozniatowski, K., Kurzydlowski, K.J., 2001, “Quantitative characteristics of FeCrAl films deposited by arc and high-velocity arc spraying,” Materials Characterization, 46, pp.99–104.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2009 Tsinghua University Press, Beijing and Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Han, Y.H., Li, L. (2009). Erosion-Wear Behavior and Mechanism of HVAS Coatings. In: Luo, J., Meng, Y., Shao, T., Zhao, Q. (eds) Advanced Tribology. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-03653-8_264

Download citation

DOI: https://doi.org/10.1007/978-3-642-03653-8_264

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-03652-1

Online ISBN: 978-3-642-03653-8

eBook Packages: EngineeringEngineering (R0)