Abstract

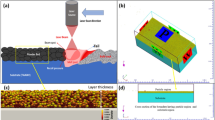

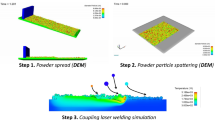

Laser Powder Bed Fusion (L-PBF) is a powder based subcategory of metal additive manufacturing. In L-PBF systems an inert gas flow is used to avoid oxidation of the metal alloy powder and components but is also used to remove unwanted by-products produced from the vaporisation of material. By-products produced during in L-PBF can cause attenuation of the laser and re-deposition of unwanted by-products over the processing area which can affect the mechanical properties of as built components. The two main by-products produced in L-PBF are spatter caused from melt pool instabilities and recoil pressure from the metal vapour plume, and particulate condensates. A multiphase computational fluid dynamics model developed in ANSYS Fluent simulates the argon gas flow in a Renishaw AM250 machine validated using hotwire anemometry testing. This model is then coupled with a spatter expulsion discrete phase model supported by high speed imaging analysis and a tertiary phase model for a representative expulsion of particulate condensates is developed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Liu Y, Yang Y, Mai S, Wang D, Song C (2015) Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder. Mater Des 87:797–806

Simonelli M, Tuck C, Aboulkhair NT, Maskery I, Ashcroft I, Wildman RD, Hague R (2015) A study on the laser spatter and the oxidation reactions during selective laser melting of 316L stainless steel, Al-Si10-Mg, and Ti-6Al-4V. Metall Mater Trans A 46(9):3842–3851

Ferrar B, Mullen L, Jones E, Stamp R, Sutcliffe CJ (2012) Gas flow effects on selective laser melting (SLM) manufacturing performance. J Mater Process Technol 212(2):355–364

Bin Anwar A, Pham QC (2017) Selective laser melting of AlSi10 Mg: effects of scan direction, part placement and inert gas flow velocity on tensile strength. J Mater Process Technol 240:388–396

Ladewig A, Schlick G, Fisser M, Schulze V, Glatzel U (2016) Influence of the shielding gas flow on the removal of process by-products in the selective laser melting process. Addit Manufact 10:1–9

Masmoudi A, Bolot R, Coddet C (2015) Investigation of the laser–powder–atmosphere interaction zone during the selective laser melting process. J Mater Process Technol 225:122–132

Ding J, Colegrove P, Martina F, Williams S, Wiktorowicz R, Palt MR (2015) Development of a laminar flow local shielding device for wire+arc additive manufacture. J Mater Process Technol 226:99–105

Sbalzarini IF, Koumoutsakos P (2005) Feature point tracking and trajectory analysis for video imaging in cell biology. J Struct Biol 151(2):182–195

Acknowledgements

The authors would like to thank the Additive Manufacturing Products Division at Renishaw Plc., and the Engineering Doctoral Training schemes MATTER (ESPRC funded) and Materials and Manufacturing Academy M2A (European Social Fund). In addition, the authors would like to acknowledge the Centre for Materials Advanced Characterisation (MACH1) for the use of state-of-the-art equipment funded by the Welsh Government and the Advanced Sustainable Manufacturing Technologies (ASTUTE 2020) funded by the Welsh European Funding Office.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Philo, A.M. et al. (2018). A Multiphase CFD Model for the Prediction of Particulate Accumulation in a Laser Powder Bed Fusion Process. In: Nastac, L., Pericleous, K., Sabau, A., Zhang, L., Thomas, B. (eds) CFD Modeling and Simulation in Materials Processing 2018. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72059-3_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-72059-3_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72058-6

Online ISBN: 978-3-319-72059-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)