Abstract

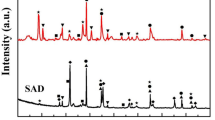

A processing technology was developed for alumina extraction from Al dross with the calcining-leaching process. The aluminum dross was mixed with soda and sintered at 1173K to yield soluble aluminates. Subsequently the sintered dross was leached with sulfuric acid to produce a solution containing aluminum. The unwanted metal ions, including Fe3+ and Na+, were removed by ethylene diamine tetraacetic acid (EDTA) and water washing. Then NH4HCO3, was added controlling the crystallization of NH4AlO(OH)HCO3, and the drying and calcining process was carried out, resulting in ultra fine Al2O3 powders with high purity. The characteristics of the Al2O3 powders were examined by means of XRD and SEM. The extraction efficiency of Al2O3 can surpass 98% by optimization of the calcination and lixiviation processes. Well-dispersed fibriform Al2O3 powders were obtained by calcining at 1000°C and the purity of the ultra fine Al2O3 powders was more than 99.36%.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

O. Manfredi and W. Wuth, “Characterizing the physical and chemical properties of aluminum dross,” JOM, 49(1997), 48d–51.

F.A. Lopez et al., “The recovery of alumina from salt slags in aluminium remelting,” Canadian Metallurgical Quarterly, 33(1994), 29–33.

H.N. Yoshimura and A.P. Abreu, “Evaluation of aluminum dross waste as raw material for refractories,” Ceramics International, 34(3)(2008), 581–591.

El-Katatny, E.A., Halany, and S.A., Mohamed, “Surface composition, charge and texture of active alumina powders recovered from aluminum dross tailings chemical waste,” Powder Technol, 132, 2003, 137–144.

LIU Qingsheng, “Preliminary research on preparation Al-Si-Ti alloy with aluminum dross as electrolysis materials”. TMS,EPD congress, 2010, 639–644.

B. Dash and B.R. Das, “Acid dissolution of alumina from waste aluminium dross,” Hydrometallurgy, 92(2008), 48–53.

B. R. Das, et al., “Production of alumina from waste aluminium dross,” Minerals Engineering, 20(2007), 252–258.

Amer, A.M., 2002, “Extracting aluminum from dross tailings,” J. Metals, 54(2002), 72–75.

MIKITO UEDA and SHIRO TSUKAMOTO, “Recovery of aluminum from oxide particles in aluminum dross using AlF-NaF-BaCl2 molten salt,” Journal of Applied Electrochemistry, 35(2005), 925–930.

XIAO Y. YAN, “Chemical and electrochemical processing of aluminum dross using molten salts,” METALLURGICAL AND MATERIALS TRANSACTIONS B, 348, 2008, 348–363.

MATJIE R. H., et al., “Extraction of alumina from coal fly ash generated from a selected low rank bituminous South African coal,” Min Eng, 18(2005), 299–310.

AKIRA O, et al., “Leaching of various metals from coal into aqueous solutions containing an acid or a chelating agent,” Fuel Process Technol, 85(2004), 1089–1 102.

IYER R S and SCOTT J A, “Power station fly ash—a review of value-added utilization outside of the construction industry,” Resour Conserv Recycl, 31(2001), 217–288.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Qingsheng, L., Chunming, Z., Hui, F., Jilai, X. (2011). High Purity Alumina Powders Extracted from Aluminum Dross by the Calcining—Leaching Process. In: Lindsay, S.J. (eds) Light Metals 2011. Springer, Cham. https://doi.org/10.1007/978-3-319-48160-9_34

Download citation

DOI: https://doi.org/10.1007/978-3-319-48160-9_34

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48567-6

Online ISBN: 978-3-319-48160-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)