Abstract

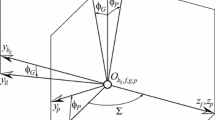

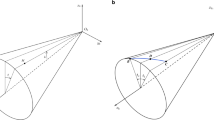

The ease-off concept was introduced to describe the mismatch, a deviation between conjugation and non-conjugation, between two tooth surfaces from a pair of mating bevel gears in contact. However, a complete mathematical description of ease-off and the algorithm of computation were not found. The application of ease-off concept in tooth contact analysis (TCA) allows for a numerical determination of contact patterns and transmission errors of highly conformable contact or almost conjugate contact of tooth surfaces. The paper analytically describes a generalized theory of ease-off and its application in tooth contact analysis of both face-milled and face-hobbed spiral bevel and hypoid gears with complex tooth surface modifications. The implementation of the ease-off algorithm applied to the tooth contact analysis is illustrated with two examples of, respectively, a face-milled gear drive and a face-hobbed hypoid gear drive.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Baxter ML (1966) Exact determination of tooth surfaces for spiral bevel and hypoid gears, AGMA Semi-Annual Meeting, p 139

Baxter M L (1973) Second-order surface generation, J Ind Math Soc, vol 23, p 2

Fan Q (2006) Computerized modeling and simulation of spiral bevel and hypoid gears manufactured by gleason face hobbing process. ASME J Mech Des 128(6):1315–1327

Fan Q (2007) Enhanced algorithms of contact simulation for hypoid gear drives produced by face-milling and face-hobbing processes. ASME J Mech Des 129(1):31–37

Fan Q, DaFoe R, Swanger J (2008) Higher-order tooth flank form error correction for face-milled spiral bevel and hypoid gears. ASME J Mech Des 130(7):072601

Fan Q (2010) Tooth surface error correction for face-hobbed hypoid gears. ASME J Mech Des 132(1):011004

Fan Q (2011) Optimization of face cone element for spiral bevel and hypoid gears. ASME J Mech Des 133(9):091002

Fuentes A, Gonzalez-Perez I, Litvin FL, Hayasaka K, Yukishima K (2005) Design, manufacture, and evaluation of prototypes of low-noise high-endurance spiral bevel gear drives, ASME IDETC/CIE, PTG, DETC2005-84013. Long Beach, USA

Kolivand M, Kahraman A (2010) An ease-off based method for loaded tooth contact analysis of hypoid gears having local and global surface deviations. ASME J Mech Des 132(7):071004

Krenzer TJ (1984) Computer aided corrective machine settings for manufacturing bevel and hypoid gear sets. Fall Technical Meeting, Washington, D.C

Krenzer TJ (2007) The bevel gear, published by Ted Krenzer, New York

Litvin FL (1994) Gear geometry and applied theory, Prentice Hall, New Jersey

Litvin FL, Fan Q, Fuentes A, Handschuh R F (2001) Computerized design, generation, simulation of meshing and contact of face-milled formateTM-cut spiral bevel gears, NASA Report, /CR-2001-210894, ARL-CR-467

Shih YP, Fong ZH, Lin GCY (2007) Mathematical model for a universal face hobbing hypoid gear generator. ASME J Mech Des 129(1):38–47

Simon V (2007) Load distribution in spiral bevel gears. ASME J Mech Des 129(2):201–209

Stadtfeld HJ (2000) Advanced bevel gear technology, The Gleason Works, New York

Stadtfeld HJ, Gaiser U (2000) The ultimate motion graph. ASME J Mech Des 122(3):317–322

Stadtfeld HJ (2003) The two-sided-ground bevel gear cutting tool. Gear Technology, May/Jun

Stadtfeld HJ (2008) gear encyclopedia, The Gleason Works, New York

Stadtfeld HJ (2010) Tribology aspects in angular transmission systems, Gear Technology, California, pp 46–52

Stadtfeld HJ (2012) Bevel gear cutting blade measurement, Gear Solutions, California

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Fan, Q. (2016). Ease-Off and Application in Tooth Contact Analysis for Face-Milled and Face-Hobbed Spiral Bevel and Hypoid Gears. In: Goldfarb, V., Barmina, N. (eds) Theory and Practice of Gearing and Transmissions. Mechanisms and Machine Science, vol 34. Springer, Cham. https://doi.org/10.1007/978-3-319-19740-1_15

Download citation

DOI: https://doi.org/10.1007/978-3-319-19740-1_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-19739-5

Online ISBN: 978-3-319-19740-1

eBook Packages: EngineeringEngineering (R0)