Abstract

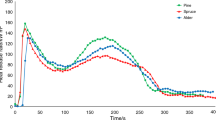

The article deals with wood dust of African Padauk (Pterocarpus soyauxii). The wood dust was prepared by Makita 9556CR 1400 W and the K36 sandpaper for various fractions (<63; 63; 71; 100; 200; 315; 500 μm) of the wood dust. The aim of the article is granulometric analysis of the wood dust of African Padauk (Pterocarpus soyauxii), to identify its morphological structure and to assess the effect of particle size of airborne dust on minimum ignition temperatures. The most frequent dust particle size was represented by 100 μm fraction (42.14 ± 1.049%). The minimum ignition temperature of airborne dust was 370 °C the 71 μm fraction.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

CARO DREVA (2019) Domáce drevo alebo exotika? Dostupné z: https://carodreva.sk/drevo-v-kocke/domace-drevo-alebo-exotika. Accessed 13 June 2019

Van Gemerden B, Shu GN, Olff H (2003) Recovery of conservation values in Central African rain forest after logging and shifting cultivation. Biodivers Conserv 12:1553. https://doi.org/10.1023/A:1023603813163

Fan MZ, Ndikontar MK, Zhou XM, Ngamveng JN (2012) Cement-bonded composites made from tropical woods: compatibility of wood and cement. Constr Build Mater 36:135–140

Jankowska A (2018) Assessment of sorptive properties of selected tropical wood species. Drvna Ind 69(1):35–42. https://doi.org/10.5552/drind.2018.1733

Vigué J (2006) Dřevo od A do Z. 1. vydanie. Čestlice: Rebo Productions CZ, spol. s r. o. ISBN: 80-734-531-1

Reinprecht L, Kmeťová L, Iždinský J (2012) Fungal decay and bending properties of beech plywood overlaid with tropical veneers. J Trop For Sci 24(4):490–497

Tchinda JBS, Petrissans A, Molina S, Ndikontar MK, Mounguengui S, Dumarcay S, Gerardin P (2014) Study of the feasibility of a natural dye on cellulosic textile supports by red padouk (Pterocarpus soyauxii) and yellow movingui (Distemonanthus benthamianus) extracts. Ind Crops Prod 60:291–297. https://doi.org/10.1016/j.indcrop.2014.06.029

Brémaud I, Nadine A, Minato K, Gril J, Thibaut B (2011) Effect of extractives on vibrational properties of African Padauk (Pterocarpus soyauxii Taub.) August 2011. Wood Sci Technol 45(3):461–472. https://doi.org/10.1007/s00226-010-0337-3

Straze A, Mitkovski B, Tippner J, Cufar K, Gorisek Z (2015) Structural and acoustic properties of African padouk (Pterocarpus soyauxii) wood for xylophones. Eur J Wood Wood Prod 73(2):235–243

Bernard O, Rostand MP, Evelyne T, Michel G (2018) Experimental investigation of mixed mode fracture of tropical wood material. In: Sedmak A, Radakovic Z, Rakin M (eds) Book series: procedia structural integrity, vol 13, pp 347–352. https://doi.org/10.1016/j.prostr.2018.12.058

Marková I, Mračková E, Očkajová A, Ladomerský J (2016) Granulomerty of selectes wood dust species of duat from orbital sanders. Wood Res 61(6):983–992

Dzurenda L, Orlowski KA, Grzeskiewicz M (2010) Effect of thermal modification of oak wood on sawdust granularity. Drvna Ind 61(2):89–94

Dzurenda L, Orlowski KA (2011) The effect of thermal modification of ash wood on granularity and homogeneity of sawdust in the sawing process on a sash gang saw prw 15-M in view of its technological usefulness. Drewno 54(186):27–37

Eckhoff RK (2003) Dust explosions in the process industries. Gulf Professional Publishing, Boston, 719 s. ISBN 978-0750676021

Očkajová A, Kučerka M, Krišťák Ľ, Igaz R (2018) Granulometric analysis of sanding dust from selected wood species. BioResources 13(4):7481–7495

Mračková E, Krišták Ľ, Kučera M, Gaff M, Gajtanská M (2016) Creation of wood dust during wood processing: size analysis, dust separation, and occupational health. BioResources 11(1):209–222

Rohr AC, Campleman SL, Long CM, PetersonN MK, Weatherstone S, Quick W, Lewis A (2015) Potential occupational exposures and health risks associated with biomass-based power generation. Int J Environ Res Public Health 12(7):8542–8605. https://doi.org/10.3390/ijerph120708542

Kovshov S, Nikulin A, Kovshov V, Mračková E (2015) Application of equipment for aerological researching of characteristics of wood dust. Acta Fac Xylol Zvolen 57(1):111–118

Amyotte P (2013) An introduction to dust explosions: understanding the myths and realities of dust explosions for a safer workplace. In: An introduction to dust explosions: understanding the myths and realities of dust explosions for a safer workplace. Elsevier Inc. http://www.scopus.com/inward/record.url?eid=2-s2.0-84899749632-&partnerID=tZOtx3y1

Amyotte PR, Eckhoff RK (2010) Dust explosion causation, prevention and mitigation: an overview. J Chem Health Saf 17(1):15–28. https://doi.org/10.1016/j.jchas.2009.05.002

Žigo J, Rantuch P, Balog K (2014) Experimental analysis of minimum ignition temperature of dust cloud obtained from thermally modified spruce wood. Adv Mater Res 919-921, 2057–2060. http://doi.org/10.4028/www.scientific.net-/AMR.919-921.2057

Krentowski J (2015) Disaster of an industrial hall caused by an explosion of wood dust and fire. Eng Failure Anal 56:403–411. https://doi.org/10.1016/j.engfailanal.2014.12.015

Marková I, Ladomerský J, Hroncová E, Mračková E (2018) Thermal parameters of beech wood dust. BioResources 13(2):3098–3109

Top Y, Adanur H, Öz M (2016) Comparison of practices related to occupational health and safety in microscale wood-product enterprises. Saf Sci 82:374–381. https://doi.org/10.1016/j.ssci.2015.10.014

EN 50281-2-1 (2002) Electrical apparatus for use in the presence of combustible dust. Part 2-1: test methods. Methods for determining the minimum ignition temperatures of dust. European Committee for Standardization, Brussels, Belgium

Marková I, Hroncová E, Tomaškin J, Tureková E (2018) Thermal ananlysis of granulometry selected wood dust. BioResources 13(4):8041–8060

Misse SE, Brillard A, Brilhac J-F, Obonou M, Ayina LM, Schönnenbeck C, Caillat S (2018) Thermogravimetric analyses and kinetic modeling of three Cameroonian biomass. J Ther Anal Calorimetry 132(3):1979–1994. https://doi.org/10.1007/s10973-018-7108-z

Mračková E, Milanko V (2016) Characteristics of wood particulates as a function of safety parameters. CRC Press, Balkema, pp 487–490

IAWA list of microscopic features for hardwood identification with an Appendix on non-anatomical information IAWA Committee (1989) IAWA Bulletin n. s. vol 10, no 3, pp 219–332. www.iawa-website.org/uploads/soft/Abstracts/IAWA%20list%20of%20microscopic%20features%20for%20hardwood%20identification.pdf

Wang Y, Su M, Sun H, Ren H (2018) Comparative studies on microstructures and chemical compositions of cell walls of two solid wood floorings. J Wood Sci. https://doi.org/10.1007/s10086-018-1743-7

Tureková I (2008) Riziká priemyselných drevných prachov. In: Rusko M (ed) Zborník z XII. Konferencie so zahraničnou účasťou, 5–6 December 2008, Bratislava. Strix et VeV. Prvé vydanie, Žilina, pp 167–175. ISBN 978-80-89281-34-3

STN ISO 871 (1999) Plastics. Determination of ignition temperature using a hot-air furnace

Martinka J, Rantuch P (2013) Posúdenie vplyvu veľkosti častíc dubového dreva na teplotu vznietennia rozvíreného prachu. Acta Fac Tech XVIII 2013(2):75–82

Kasalová I, Balog K (2010) Minimum ignition temperatures of wood dust clouds determi -ned by planed experiment. In: Fire engineering, Zvolen, 5th–6th October 2010. Bratia Sabovci, Zvolen, pp 119–126. ISBN 978-80-89241-38-8

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Vandličková, M., Marková, I. (2020). Ignition of Wood Dust of African Padauk (Pterocarpus Soyauxii). In: Makovicka Osvaldova, L., Markert, F., Zelinka, S. (eds) Wood & Fire Safety. WFS 2020. Springer, Cham. https://doi.org/10.1007/978-3-030-41235-7_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-41235-7_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-41234-0

Online ISBN: 978-3-030-41235-7

eBook Packages: EngineeringEngineering (R0)