Abstract

Fish and feed waste provide most of the nutrients required by the plants in aquaponics if the optimum ratio between daily fish feed inputs and the plant growing area is sustained. Thus, the fish feed needs to fulfil both the fish’s and plant’s nutritional requirements in an aquaponic system. A controlled fish waste production strategy where the nitrogen, phosphorus and mineral contents of fish diets are manipulated and used provides a way of influencing the rates of accumulation of nutrients, thereby reducing the need for the additional supplementation of nutrients. To optimize the performance and cost-effectiveness of aquaponic production, fish diets and feeding schedules should be designed carefully to provide nutrients at the right level and time to complement fish, bacteria and plants. To achieve this, a species-specific tailor-made aquaponic feed may be optimized to suit the aquaponic system as a whole. The optimal point would be determined based on overall system performance parameters, including economic and environmental sustainability measures. This chapter thus focuses on fish diets and feed and reviews the state of the art in fish diets, ingredients and additives, as well as the nutritional/sustainable challenges that need to be considered when producing specific aquaponic feeds.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Aquatic food is recognized to be beneficial to human nutrition and health and will play an essential role in future sustainable healthy diets (Beveridge et al. 2013). In order to achieve this, the global aquaculture sector must contribute to increasing the quantity and quality of fish supplies between now and 2030 (Thilsted et al. 2016). This growth should be promoted not only by increasing the production and/or number of species but also by systems diversification. However, fish from aquaculture has only recently been included in the food security and nutrition (FSN) debate and the future strategies and policies, demonstrating the important role of this production to prevent malnutrition in the future (Bénét et al. 2015), as fish provide a good source of protein and unsaturated fats, as well as minerals and vitamins. It is important to note that many African nations are promoting aquaculture as the answer to some of their current and future food production challenges. Even in Europe, fish supply is currently not self-sufficient (with an unbalanced domestic supply/demand), being increasingly dependent on imports. Therefore, ensuring the successful and sustainable development of global aquaculture is an imperative agenda for the global and European economy (Kobayashi et al. 2015). Sustainability is generally required to show three key aspects: environmental acceptability, social equitability and economic viability. Aquaponic systems provide an opportunity to be sustainable, by combining both animal and plant production systems in a cost-efficient, environmentally friendly and socially beneficial ways. For Staples and Funge-Smith (2009), sustainable development is the balance between ecological well-being and human well-being, and in the case of aquaculture, an ecosystem approach has been only recently understood as a priority area for research.

Aquaculture has been the fastest growing food production sector during the last 40 years (Tveterås et al. 2012), being one of the most promising farming activities to meet near-future world food needs (Kobayashi et al. 2015). Total production statistics from aquaculture (FAO 2015) reveal an annual increment in global production of 6%, which is expected to provide up to 63% of global fish consumption by 2030 (FAO 2014), for an estimated population of nine billion people in 2050. In the case of Europe, the predicted increase is seen not only within the marine sector but also in terrestrially produced products. Some of the expected challenges to the growth of aquaculture during the coming years are the reduction in the use of antibiotics and other pathological treatments, the development of efficient aquaculture systems and equipment, together with species diversification and increased sustainability in the area of feed production and feed use. The shift from fishmeal (FM) in feed to other protein sources is also an important challenge, as well as the ‘fish-in-fish-out’ ratios. There is a long history, reaching back to the 1960s, of promoting the growth of the aquaculture sector towards proper sustainability including the encouragement to adapt and create new and more sustainable feed formulas, reduce feed spilling and reduce the food conversion ratio (FCR). Although aquaculture is recognized as the most efficient animal production sector, when compared with terrestrial animal production, there is still room for improvement in terms of resource efficiency, diversification of species or methods of production, and moreover a clear need for an ecosystem approach taking full advantage of the biological potential of the organisms and providing adequate consideration of environmental and societal factors (Kaushik 2017). This growth in aquaculture production will need to be supported by an increase in the expected total feed production. Approximately three million additional tons of feed will need to be produced each year to support the expected aquaculture growth by 2030. Moreover, replacing fishmeal and fish oil (FO) with plant and terrestrial substitutes is needed which requires essential research into formula feed for animal farming.

The animal and aquafeed industries are part of a global production sector, which is also the focus for future development strategies. Alltech’s yearly survey (Alltech 2017) reveals that total animal feed production broke through 1 billion metric tons, with a 3.7% increase in production from 2015 despite a 7% decrease in the number of feed mills. China and the USA dominated production in 2016, accounting for 35% of the world’s total feed production. The survey indicates that the top 10 producing countries have more than half of the world’s feed mills (56%) and account for 60% of total feed production. This concentration in production means that many of the key ingredients traditionally used in formulations for commercial aquaculture feeds are internationally traded commodities, which subjects aquafeed production to any global market volatility. Fishmeal for example is expected to double in price by 2030, whilst fish oil is likely to increase by over 70% (Msangi et al. 2013). This illustrates the importance of reducing the amount of these ingredients in fish feed whilst increasing the interest and focus on new or alternative sources (García-Romero et al. 2014a, b; Robaina et al. 1998, 1999; Terova et al. 2013; Torrecillas et al. 2017).

Whilst new offshore platforms have been developed for aquaculture production, there is also a significant focus on marine and freshwater recirculating aquaculture systems (RAS), as these systems use less water per kg fish feed used, which increases fish production whilst reducing environmental impacts of aquaculture including reductions in water usage (Ebeling and Timmons 2012; Kingler and Naylor 2012). RAS can be integrated with plant production in aquaponic systems, which readily fit into local and regional food system models (see Chap. 15) that can be practised in or near large population centres (Love et al. 2015a). Water, energy and fish feed are the three largest physical inputs for aquaponic systems (Love et al. 2014, 2015b). Approximately 5% of feed is not consumed by the farmed fish, whilst the remaining 95% is ingested and digested (Khakyzadeh et al. 2015). Of this share, 30–40% is retained and converted into new biomass, whilst the remaining 60–70% is released in the form of faeces, urine and ammonia (FAO 2014). On average, 1 kg of feed (30% crude protein) globally releases about 27.6 g of N, and 1 kg of fish biomass releases about 577 g of BOD (biological oxygen demand), 90.4 g of N and 10.5 g of P (Tyson et al. 2011).

Aquaponics is currently a small but rapidly growing sector which is clearly suited to take advantage of the following political and socio-economic challenges, where 1) aquatic produce meets the need for food security and nutrition, 2) fish self-sufficient regions are established around the world, 3) aquaculture is a key sector but global ingredients and global feed production comes under focus, 4) innovation in agriculture promotes biodiversity in more sustainable ways and as part of the circular economy and 5) there is a greater take up of locally produced foods. These aspects tie in with the recommendations from the International Union for the Conservation of Nature (Le Gouvello et al. 2017), regarded the sustainability of the aquaculture and fish feed, which has recommended that efforts should be made to localize aquaculture production and the circular approach, and for putting in place a quality control programme for new products and by-products, as well as processing local fish feed within regions. So far, aquaponics as ‘small-scale aquaculture farms’ could provide examples for the implementation of the bioeconomy and local-scale production, thus promoting ways of using products and by-products from organic matter not suitable for use for other purposes, e.g. farmed insects and worms, macro- and microalgae, fish and by-product hydrolysates, new agro-ecology-produced plants and locally produced bioactives and micronutrients, whilst reducing the environmental footprint with quality food (fish and plants) production and moving towards zero waste generation. Moreover, aquaponics provides a good example for promoting a multidisciplinary way of learning about sustainable production and bioresource valorization, e.g. the ‘Islandap Project’ (INTERREG V-A MAC 2014-2020) (Fig. 13.1).

The following sections of this chapter review the state of the art of fish diets, ingredients and additives, as well as nutritional/sustainable challenges to consider when producing specific aquaponic feeds.

2 Sustainable Development of Fish Nutrition

The sustainable development of fish nutrition in aquaculture will need to correspond with the challenges that aquaponics delivers with respect to the growing need for producing high-quality food. Manipulating the nitrogen, phosphorus and the mineral content of fish diets used in aquaponics is one way of influencing the rates of the accumulation of nutrients, thereby reducing the need for the artificial and external supplementation of nutrients. According to Rakocy et al. (2004), fish and feed waste provide most of the nutrients required by plants if the optimum ratio between daily fish feed input and plant growing areas is sustained. Solid fish waste called ‘sludge’ in aquaponic systems results in losing approximately half of the available input nutrients, especially phosphorus, that theoretically could be used for plant biomass production but information is still limited (Delaide et al. 2017; Goddek et al. 2018). Whilst the goal of sustainability in fish nutrition in aquaculture will in the future be achieved by using tailor-made diets, fish feed in aquaponics needs to fulfil the nutritional requirements both for fish and for plants. Increases in sustainability will in part derive from less dependence on fishmeal (FM) and fish oil (FO) and novel, high-energy, low-carbon footprint raw natural ingredients. To safeguard biodiversity and the sustainable use of natural resources, the use of wild fisheries-based FM and FO needs to be limited in aquafeeds (Tacon and Metian 2015). However, fish performance, health and final product quality may be altered when substituting dietary FM with alternative ingredients. Thus, fish nutrition research is focused on the efficient use and transformation of the dietary components to provide the necessary essential nutrients that will maximize growth performance and achieve sustainable and resilient aquaculture. Replacing FM, which is an excellent but costly protein source in fish diets, is not straightforward due to its unique amino acid profile, high nutrient digestibility, high palatability, adequate amounts of micronutrients, as well as having a general lack of anti-nutritional factors (Gatlin et al. 2007).

Many studies have shown that FM can be successfully replaced by soybean meal in aquafeeds, but soybean meal has anti-nutritional factors such as trypsin inhibitors, soybean agglutinin and saponin, which limit its use and high replacement percentages in farming carnivorous fish. High FM replacement by plant meals in fish diets can also reduce nutrient bioavailability in fish, which results in nutrient alterations in the final quality of the product (Gatlin et al. 2007). It can also cause undesirable disturbances to the aquatic environment (Hardy 2010) and reduce fish growth due to the reduced levels of essential amino acids (especially methionine and lysine), and reduced palatability (Krogdahl et al. 2010). Gerile and Pirhonen (2017) noted that a 100% FM replacement with corn gluten meal significantly reduced growth rate of rainbow trout but FM replacement did not affect oxygen consumption or swimming capacity.

High levels of plant material can also affect the physical quality of the pellets, and may complicate the manufacturing process during extrusion. Most of the alternative plant-derived nutrient sources for fish feeds contain a wide variety of anti-nutritional factors that interfere with fish protein metabolism by impairing digestion and utilization, therefore leading to increased N release in the environment which can affect fish health and welfare. In addition, diets including high levels of phytic acid altered phosphorus and protein digestion that lead to high N and P release into the surrounding environment. Feed intake and palatability, nutrient digestibility and retention may vary according to fish species’ tolerance and levels and can change the quantity and composition of the fish waste. Taking into consideration these results, fish diet formulations in aquaponics should investigate ‘the tolerance’ dietary levels of anti-nutritional factors (i.e. phytate) for different feed ingredients and for each fish species used in aquaponics and also the effects of the addition of minerals such as Zn and phosphate in the diets. It also should be noted that even if plant material is regarded as an ecologically sound option to replace FM in aquafeeds, plants need irrigation, and thus may induce ecological impacts in the form of their water and ecological footprints (Pahlow et al. 2015) from nutrient run-off from the fields.

Terrestrial animal by-products such as non-ruminant processed animal proteins (PAPs) derived from monogastric farmed animals (e.g. poultry, pork) that are fit for human consumption at the point of slaughter (Category 3 materials, EC regulation 142/2011; ΕC regulation 56/2013) could also replace FM and support the circular economy. They have higher protein content, more favourable amino acid profiles and fewer carbohydrates compared to plant feed ingredients whilst also lacking anti-nutritional factors (Hertrampf and Piedad-Pascual 2000). It has been shown that meat and bone meals may serve as a good phosphorus source when it is included in the diet of Nile tilapia (Ashraf et al. 2013), although it has been strictly banned in the feed of ruminant animals due to the danger of initiating bovine spongiform encephalopathy (mad cow disease). Certain insect species, such as black soldier fly (Hermetia illucens), could be used as an alternative protein source for sustainable fish feed diets. The major environmental advantages of insect farming are that (a) less land and water are required, (b) that greenhouse gas emissions are lower and that (c) insects have high feed conversion efficiencies (Henry et al. 2015). However, there is a continuing need for further research to provide evidence on quality and safety issues and screening for risks to fish, plants, people and the environment.

It is important to note that fish cannot synthesize several essential nutrients required for their metabolism and growth and depend on the feed for this supply. However, there are certain animal groups that can use nutrient-deficient diets, as they bear symbiotic microorganisms that can provide these compounds (Douglas 2010), and thus, fish can obtain maximal benefit when the microbial supply of their essential nutrients is scaled to demand. Undersupply limits fish growth, whilst oversupply can be harmful due to the need for the fish to neutralize toxicity caused by non-essential compounds. The extent to which the microbial function varies with the demands of different fish species and what are the underlying mechanisms are largely unknown. Importantly, an aquatic animal’s gut microbiota can in theory play a critical role in providing the necessary nutrients and obtaining sustainability in fish farming (Kormas et al. 2014; Mente et al. 2016). Further research in this field will help facilitate the selection of ingredients to be used in fish feeds that promote gut microbiota diversity to improve fish growth and health.

Research into the utilization of alternative plant and animal protein sources and low trophic fish feed ingredients is ongoing. The substitution of marine sourced raw ingredients in fish feed, which could be used directly for human food purposes should decrease fishing pressure and contribute to preserving biodiversity. Low trophic-level organisms, such as black soldier fly, which may serve as aquafeed ingredients may be grown on by-products and waste of other agricultural industrial practices given different nutritional quality meals, thereby adding additional environmental benefits. However, efforts to succeed with the circular economy and the recycling of organic and inorganic nutrients should be handled with care since undesirable compounds in raw materials and seafood products could increase the risk to animal health, welfare, growth performance and safety of the final product for consumers. Research and continuous monitoring and reporting on contaminants of farmed aquatic animals in relation to the maximum limits in feed ingredients and diets are essential to inform revisions in and introductions of new regulations.

3 Feed Ingredients and Additives

3.1 Protein and Lipid Sources for Aquafeeds

Since the end of the twentieth century, there have been significant changes in the composition of aquafeeds but also advances in manufacturing. These transformations have originated from the need to improve the economic profitability of aquaculture as well as to mitigate its environmental impacts. However, the driving forces behind these changes is the need to decrease the amount of fishmeal (FM) and fish oil (FO) in the feeds, which have traditionally constituted the largest proportion of the feeds, especially for carnivorous fish and shrimp. Partly because of overfishing but especially due to the continuous increase in global aquaculture volume, there is an increasing need for alternative proteins and oils to replace FM and FO in aquafeeds.

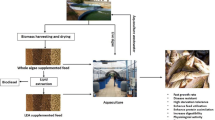

The composition of fish feeds has changed considerably as the proportion of FM in diets has decreased from >60% in the 1990s to <20% in modern diets for carnivorous fish such as Atlantic salmon (Salmo salar), and FO content has decreased from 24% to 10% (Ytrestøyl et al. 2015). As a consequence the so-called fish-in-fish-out (FIFO) ratio has decreased below 1 for salmon and rainbow trout meaning that the amount of fish needed in the feed to produce 1 kg of fish meat is less than 1 kg (Fig. 13.2). Thus, carnivorous fish culture in the twenty-first century is a net producer of fish. On the other hand, feeds for lower trophic omnivorous fish species (e.g. carp and tilapia) may contain less than 5% FM (Tacon et al. 2011). Farming such low trophic fish species is ecologically more sustainable than for higher trophic species, and FIFO for tilapia was 0.15 and for cyprinids (carp species) only 0.02 in 2015 (IFFO). It should be noted that total FM replacement in the diets of tilapia (Koch et al. 2016) and salmon (Davidson et al. 2018) is not possible without significantly affecting production parameters.

Fish-in-fish-out ratio (blue line, left y-axis) and the amount of fish oil used (yellow line, right y-axis) for rainbow trout feed in Finland between 1990 and 2013. (Data from www.raisioagro.com)

Today, the major supply of proteins and lipids in fish feed comes from plants, but also commonly from other sectors, including meals and fats from meat and poultry by-products and blood meal (Tacon and Metian 2008). Additionally, waste and by-products from fish processing (offal and waste trimmings) are commonly used to produce FM and FO. However, due to EU regulations (EC 2009), the use of FM of a species is not allowed as feed for the same species, e.g. salmon cannot be fed FM containing salmon trimmings.

FM and FO replacements with other ingredients can affect the quality of the product that is sold to customers. Fish has the reputation of being a healthy food, especially due to its high content of poly and highly unsaturated fatty acids. Most importantly, seafood is the only source of EPA (eicosapentaenoic acid) and DHA (docosahexaenoic acid), both of which are omega-3 fatty acids, and essential nutrients for many functions in the human body. If FM and FO are replaced with products from terrestrial origin, this will directly affect the quality of the fish flesh, most of all its fatty acid composition, as the proportion of omega-3 fatty acids (especially EPA and DHA) will decrease whilst the amount of omega-6 fatty acids will increase along with the increase of plant material that is replacing FM and FO (Lazzarotto et al. 2018). As such, the health benefits of fish consumption are partly lost, and the product that ends up on the plate is not necessarily what consumers expected to buy. However, in order to overcome the problem of decreased omega-3 fatty acids in the final product resulting from lower fish ingredients in aquafeeds, fish farmers could employ so-called finishing diets with high FO content during the final stages of cultivation (Suomela et al. 2017).

A new interesting option for replacing FO in fish feeds is the possibility of genetic engineering, i.e. genetically modified plants which can produce EPA and DHA, e.g. oil from genetically modified Camelina sativa (common name of camelina, gold-of-pleasure or false flax which is known to have high levels of omega-3 fatty acids) was successfully used to grow salmon, ending up with very high concentration on EPA and DHA in the fish (Betancor et al. 2017). The use of genetically modified organisms in human food production, however, is subject to regulatory approval and may not be an option in the short term.

Another new possibility to replace FM in aquafeeds is proteins made of insects (Makkar et al. 2014). This new option has become possible within the EU only recently when the EU changed legislation, allowing insect meals in aquafeeds (EU 2017). The species permitted to be used are black soldier fly (Hermetia illucens), common housefly (Musca domestica), yellow mealworm (Tenebrio molitor), lesser mealworm (Alphitobius diaperinus), house cricket (Acheta domesticus), banded cricket (Gryllodes sigillatus) and field cricket (Gryllus assimilis). Insects must be reared on certain permitted substrates. Growth experiments done with different fish species show that replacing FM with meal made of black soldier fly larvae does not necessarily compromise growth and other production parameters (Van Huis and Oonincx 2017). On the other hand, meals made of yellow mealworm could replace FM only partially to avoid decrease in growth (Van Huis and Oonincx 2017). However, FM replacement with insect meal can cause a drop in omega-3 fatty acids, as they are void of EPA and DHA (Makkar and Ankers 2014).

In contrast to insects, microalgae typically have nutritionally favourable amino acid and fatty acid (including EPA and DHA) profiles but there is also a wide variation between species in this respect. Partial replacement of FM and FO in aquafeeds with certain microalgae have given promising results (Camacho-Rodríguez et al. 2017; Shah et al. 2018) and in the future the use of microalgae in aquafeeds can be expected to increase (White 2017) even though their use may be limited by price.

This short summary of potential feed ingredients indicates that there is wide range of possibilities to at least partially replace FM and FO in fish feeds. In general, the amino acid profile of FM is optimal for most fish species and FO contains DHA and EPA which are practically impossible to provide from terrestrial oils, albeit genetic engineering may change the situation in the future. However, GMO products need first to be accepted in legislation and then by customers.

3.2 The Use of Specialist Feed Additives Tailored for Aquaponics

Tailoring aquafeeds which are specific to aquaponic systems is more challenging than conventional aquaculture feed development, as the nature of aquaponic systems requires that the aquafeeds not only supply nutrition to the cultured animals but also to the cultured plants and the microbial communities inhabiting the system. Current aquaponic practice utilizes aquafeeds formulated to provide optimal nutrition to the cultured aquatic animals; however, as the major nutrient input into aquaponic systems (Roosta and Hamidpour 2011; Tyson et al. 2011; Junge et al. 2017), the feeds also need to take into account the nutrient requirements of the plant production component. This is especially important for commercial-scale aquaponic systems, where the productivity of the plant production system has a major impact on overall system profitability (Adler et al. 2000; Palm et al. 2014; Love et al. 2015a) and where improved production performance of the plant component can significantly improve overall system profitability.

Thus, the overall aim of developing tailored aquaponic feeds would be to design a feed which strikes a balance between providing additional plant nutrients, whilst maintaining acceptable aquaponic system operation (i.e. sufficient water quality for animal production, biofilter and anaerobic digester performance, and nutrient absorption by plants). In order to achieve this, the final tailored aquaponic feed may not be optimal for either aquatic animal or plant production individually, but would rather be optimal for the aquaponic system as a whole. The optimal point would be determined based on overall system performance parameters, e.g. economic and/or environmental sustainability measures.

One of the major challenges in increasing production output from coupled aquaponic systems is the relatively low concentrations of both macro- and micro plant nutrients (mostly in the inorganic form) in the recirculating water, compared to conventional hydroponic systems. These low levels of nutrients can result in nutrient deficiencies in the plants and suboptimal plant production rates (Graber and Junge 2009; Kloas et al. 2015; Goddek et al. 2015; Bittsanszky et al. 2016; Delaide et al. 2017). A further challenge is the significant amounts of sodium chloride in conventional fishmeal-based aquafeeds and the potential accumulation of sodium in aquaponic systems (Treadwell et al. 2010). Different approaches can be developed to address these challenges such as technological solutions, e.g. decoupled aquaponic systems (Goddek et al. 2016) (also see Chap. 8), direct nutrient supplementation in the plant production system via foliar spray or addition to the recirculating water (Rakocy et al. 2006; Roosta and Hamidpour 2011) , or the culture of better salt-tolerant plant (see Chap. 12). A new approach is the development of tailored aquafeeds specifically for use in aquaponics.

In order to address plant nutrient shortages in aquaponics, tailored aquaponic feeds need to increase the amount of plant-available nutrients, either by increasing the concentrations of specific nutrients after excretion by the cultured animals, or by rendering the nutrients more bio-available after excretion and biotransformation, for rapid uptake by the plants. Achieving this increased nutrient excretion is, however, not as simple as supplementing increased amounts of the desired nutrients to the aquaculture diets, as there are many (often conflicting) factors that need to be considered in an integrated aquaponic system. For example, although optimal plant production will require increased concentrations of specific nutrients, certain minerals, e.g. certain forms of iron and selenium, can be toxic to fish even at low concentrations and would therefore have maximum allowable levels in the circulating water (Endut et al. 2011; Tacon 1987). Apart from total nutrient levels, the ratio between nutrients (e.g. the P:N ratio) is also important for plant production (Buzby and Lin 2014), and imbalances in the ratios between nutrients can lead to accumulation of certain nutrients in aquaponic systems (Kloas et al. 2015). Furthermore, even if an aquaponic feed increases plant nutrient levels, the overall system water quality and pH still needs to be maintained within acceptable limits to ensure acceptable animal production, efficient nutrient absorption by plant roots, optimal operation of biofilters and anaerobic digesters (Goddek et al. 2015b; Rakocy et al. 2006) and to avoid precipitation of certain important nutrients like phosphates, as this will render them unavailable to plants (Tyson et al. 2011). To achieve this overall balance is no mean feat, as there are complex interactions between the different forms of nitrogen in the system (NH3, NH4 +, NO2 −, NO3 −), the system pH and the assortment of metals and other ions present in the system (Tyson et al. 2011; Goddek et al. 2015; Bittsanszky et al. 2016).

Common Nutrient Shortages in Aquaponic Systems

Plants require a range of macro- and micronutrients for growth and development. Aquaponic systems are commonly deficient in the plant macronutrients potassium (K), phosphorus (P), iron (Fe), manganese (Mn) and sulphur (S) (Graber and Junge 2009; Roosta and Hamidpour 2011). Nitrogen (N) is present in different forms in aquaponic systems, and is excreted as part of the protein metabolism of the cultured aquatic animals (Rakocy et al. 2006; Roosta and Hamidpour 2011; Tyson et al. 2011) after which it enters the nitrogen cycle in the integrated aquaponic environment. (Nitrogen is discussed in detail in Chap. 9 and is therefore excluded from the present discussion.)

The use of selected specialist aquaculture feed additives can contribute to the development of tailored aquafeeds specifically for aquaponics, by providing additional nutrients to the cultured aquatic animals and/or plants, or by adjusting the ratio of nutrients. Aquaculture feed additives are diverse, with a wide range of functions and mechanisms of working. Functions can be nutritive and non-nutritive, and the additives can be targeted towards action in the feeds or towards the physiological processes of the cultured aquatic animals (Encarnação 2016). For the purposes of this chapter, emphasis is on three specific types of additives which could assist the tailoring of aquaponic diets: (1) mineral supplements added directly to the feeds, (2) minerals that are added co-incidentally as part of additives that serve a non-mineral purpose and (3) additives which render minerals, which are already present in the feeds, more available to the cultured aquatic animals and/or plants in aquaponic systems.

-

1.

Direct mineral supplementation in aquaponic feeds

Supplementing minerals directly in aquaculture diets used in aquaponic systems is one potential method to either increase the amount of minerals excreted by the cultured animals or to add specific minerals required by the plants in aquaponic systems. Minerals are routinely added in the form of mineral premixes to aquaculture diets, to supply the cultured aquatic animals with the essential elements required for growth and development (Ng et al. 2001; NRC 2011). Any minerals not absorbed by the fish during digestion are excreted, and if these are in the soluble (mostly ionic) form in the aquaponic system, these are available for plant uptake (Tyson et al. 2011; Goddek et al. 2015). It is unclear how feasible such an approach would be, as there is scant information about the efficacy of adding mineral supplements to aquafeeds for the purpose of enhancing aquaponic plant production. In general, mineral requirements and metabolism in aquaculture are poorly understood compared to terrestrial animal production, and the feasibility of this approach is therefore not well described. Potential advantages to this approach would be that it could prove to be a fairly simple intervention to improve overall system performance, it could allow supplementation of a wide range of nutrients, and it is likely to be relatively low cost. However, substantial research is still required to avoid any major potential pitfalls that may arise. One of these centres on the fact that the supplemented minerals destined for the plants first need to pass through the digestive tract of the cultured aquatic animals and these could either be absorbed fully or partially during this passage. This could lead to unwanted accumulation of minerals in the aquatic animals, or interference in normal intestinal nutrient and/or mineral absorption and physiological processes (Oliva-Teles 2012). Significant interactions can occur between dietary minerals in aquaculture diets (Davis and Gatlin 1996), and these need to be determined before direct mineral supplementation in aquaponic diets can be employed. Other potential effects may include altered physical structure and chemosensory characteristics of the feeds, which in turn could affect feed palatability. Clearly, there is still substantial research required before this method of tailoring aquaponic feeds can be adopted.

-

2.

Co-incidental addition of minerals by way of feed additives

Certain classes of feed additives are added to aquafeeds in the form of ionic compounds and where only one of the ions contributes towards the intended activity. The other ion is viewed as a co-incidental and unavoidable addition to the aquafeed and is often not considered in any aquaculture research. One specific example of such a class of often-used feed additives are the organic acid salts, where the intended active ingredient in the aquafeed is the anion of an organic acid (e.g. formate, acetate, butyrate or lactate) and the accompanying cation is often ignored in the cultured animals’ nutrition. Thus, if the accompanying cation is chosen purposefully to be an important macro- or micro plant nutrient, there is the potential that it could be excreted by the cultured animals into the system water and be available for uptake by the plants.

Short-chain organic acids and their salts have become well known and often used in feed additives in both terrestrial animal nutrition and in aquaculture, where the compounds are employed as performance enhancers and agents to improve disease resistance. These compounds can have different mechanisms of functioning, including acting as antimicrobials, antibiotics or growth promoters, enhancing nutrient digestibility and utilization and acting as directly metabolizable energy source (Partanen and Mroz 1999; Lückstädt 2008; Ng and Koh 2017). Either the native organic acids or their salts can be utilized in aquaculture diets, but the salt forms of the compounds are often preferred by manufacturers as they are less corrosive to feed manufacturing equipment, are less pungent and are available in solid (powder) form, which simplifies addition to formulated feed during manufacturing (Encarnação 2016; Ng and Koh 2017). For a comprehensive review on the use of organic acids and their salts in aquaculture, readers are referred to the work of Ng and Koh (2017).

Employing organic acid salts in aquaponics has the potential to have dual benefits in the system, where the anion could enhance the performance and disease resistance of the cultured aquatic animals, whilst the cation (e.g. potassium) could increase the amount of essential plant nutrients excreted. The potential advantage of this approach is that dietary inclusion levels of organic acid salts can be relatively high for a feed additive, and research regularly reports total organic acid salt inclusion of up to 2% by weight (Encarnação 2016), although commercial manufacturers tend to recommend lower levels of approximately 0.15–0.5% (Ng and Koh 2017). The cation of organic acid salts could constitute a significant proportion of the overall weight of the salt, and as these are fed daily to the cultured animals, they could contribute a significant amount of nutrients to the plants in an aquaponic system over the course of a growing season. No published research is currently available that reports findings for this line of enquiry and as with direct mineral supplementation to aquaponic feeds, this approach needs to be validated through future research to determine the fate of the cations added as part of the organic acid salts (whether they are excreted or absorbed by the aquatic animals), and whether there are any interactions with minerals or nutrients. It remains, however, an exciting future avenue of investigation.

-

3.

Feed additives that render nutrients more bio-available to plants

Increasing amounts of plant ingredients are used in formulated aquafeeds, yet minerals from plant raw materials are less bio-available to cultured aquatic animals, mainly due to the presence of anti-nutritional factors in the plant-based dietary ingredients (Naylor et al. 2009; Kumar et al. 2012; Prabhu et al. 2016). This means that a higher proportion of minerals are excreted in the faeces in bound form, requiring ‘liberation’ before being available for plant uptake. One typical example is organic phosphorus occurring as phytate, which can bind to other minerals to form insoluble compounds, where microbial action in the environment is required before the phosphorus is released as plant-available, soluble phosphate (Kumar et al. 2012).

The use of exogenous enzymes in tailored aquaponic diets could potentially contribute towards releasing increased amounts of nutrients from high-plant content aquafeeds for both animal and plant nutrition in aquaponic systems. The most often employed enzymes in aquafeeds are proteases, carbohydrates and phytases, both to improve nutrient digestion and to degrade anti-nutritional compounds like phytate (Encarnação 2016), which can result in additional nutrients being released from aquafeeds. Although it is known that exogenous enzyme supplementation leads to improved nutrient utilization in the cultured animals, it is unclear whether additional nutrients would be excreted in plant-available form, therefore avoiding a separate remineralization step in aquaponic systems (see Chap. 10). Additionally, interactions between exogenous enzymes and nutrients in different parts of the digestive tract of fish are possible (Kumar et al. 2012), which will have further implications for the amounts of nutrients excreted for plant growth. Further research is therefore also required to determine the utility of exogenous enzymes specifically for use in aquaponic feeds.

4 Physiological Rhythms: Matching Fish and Plant Nutrition

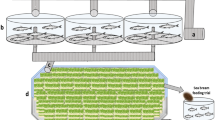

The design of feeds for fish is crucial in aquaponics because fish feed is the single or at least the main input of nutrients for both animals (macronutrients) and plants (minerals) (Fig. 13.3).

Nitrogen is introduced to the aquaponic system through protein in fish feed which is metabolized by fish and excreted in the form of ammonia. The integration of recirculating aquaculture with hydroponics can reduce the discharge of unwanted nutrients to the environment as well as generate profits. In an early economic study, phosphorus removal in an integrated trout and lettuce/basil aquaponic system proved to be cost-saving (Adler et al. 2000). Integrating fish feeding rates is also paramount to fulfil the nutritional requirements of plants. Actually, farmers need to know the amount of feed used in the aquaculture unit to calculate how much nutrient needs to be supplemented to promote plant growth in the hydroponic unit. For instance, in a tilapia-strawberry aquaponic system, the total amount of feed required to produce ions (e.g. NO3 –, Ca2 +, H2PO4 − and K+) for plants was calculated at different fish densities, with better result for small fish density 2 kg fish/m3 to reduce the cost of hydroponic solution supplementation (Villarroel et al. 2011).

It is well known that plants have daily rhythms and circadian rhythmicity in leaf movements was first described in plants by de Mairan in the early eighteenth century (McClung 2006). Circadian rhythms in plants control everything from the time of flowering to plant nutrition and thus these rhythms need to be taken into account especially when using artificial horticultural lighting. Fish are also tied into daily rhythms in most physiological functions, including feeding and nutrient uptake. It should not be surprising that fish exhibit feeding rhythms because food availability and the occurrence of predators are hardly constant but restricted to a particular time of day/night (López-Olmeda and Sánchez-Vázquez 2010). Thus, fish should be fed at the right time according to their appetite rhythms: meals scheduled during daytime for diurnal fish species, and at night for nocturnal fish. It is well known that fish show daily patterns of deamination of proteins and nitrogenous wastes related to their nutritional status and feeding rhythms (Kaushik 1980). Feeding time affects nitrogen excretion, as Gelineau et al. (1998) reported ammonia production and protein catabolism were lower in fish fed at dawn (in phase with their feeding rhythm) than in those fed at midnight (out of phase). Most interestingly, urea excretion shows circadian rhythmicity that persist in starved fish under constant conditions (Kajimura et al. 2002), revealing its endogenous origin. Furthermore, urea permeability (determined as body urea contents after immersion in a urea solution) coincided with the acrophase, i.e. the peak of the daily excretion rhythm, indicating that urea does not permeate cells by simple diffusion but there is a circadian control. Plants also show daily rhythms in nitrogen uptake, as early described by Pearson and Steer (1977), who found a daily pattern of nitrate uptake and nitrate reductase in peppers kept in a constant environment. The nitrate concentration in the leaves of spinach also increased during the night as the uptake rate of nitrate by the roots increase at that time (Steingrover et al. 1986). In aquaponics, the evidence thus points to the need for matching excretion rhythms in fish and nutrient uptake rhythms in plants. To optimize the performance and cost-effectiveness of aquaponic systems, fish diets and feeding schedules should be designed carefully to provide nutrients at the right level and the right time to complement both fish and plants.

References

Adler PR, Harper JK, Wade EM, Takeda F, Summerfelt ST (2000) Economic analysis of an aquaponic system for the integrated production of rainbow trout and plants. Int J Recirculat Aquacult 1:15–34

Alltech (2017) Alltech yearly survey 2017. https://go.alltech.com/alltech-feed-survey-2017

Ashraf S, Rania SM, Ehab REH (2013) Meat and bone meal as a potential source of phosphorus in plant-protein-based diets for Nile tilapia (Oreochromis niloticus). Aquacult Intl 21:375–385

Béné C, Barange M, Subasinghe R, Pinstrup-Andersen P, Merino G, Hemre G-I, Williams M (2015) Feeding 9 billion by 2050 – putting fish back on the menú. Food Sec 7:261–274. https://doi.org/10.1007/s12571-015-0427-z

Betancor MB, Li K, Sprague M, Bardal T, Sayanova O, Usher S, Han L, Måsøval K, Torrissen O, Napier JA, Tocher DR, Olsen RO (2017) An oil containing EPA and DHA from transgenic Camelina sativa to replace marine fish oil in feeds for Atlantic salmon (Salmo salar L.): Effects on intestinal transcriptome, histology, tissue fatty acid profiles and plasma biochemistry. PLoS ONE 12(4):e0175415. https://doi.org/10.1371/journal.pone.0175415

Beveridge MCM, Thilsted SH, Phillips MJ, Metian M, Troell M, Hall SJ (2013) Meeting the food and nutrition needs of the poor. J Fish Biol:1067. https://doi.org/10.1111/jfb.12187

Bittsanszky A, Uzinger N, Gyulai G, Mathis A, Junge R, Villarroel M, Kotzen B, Komives T (2016) Nutrient supply of plants in aquaponic systems. Ecocycles 2:17–20

Buzby KM, Lin L-S (2014) Scaling aquaponic systems: Balancing plant uptake with fish output. Aquacult Eng 63:39–44. https://doi.org/10.1016/j.aquaeng.2014.09.002.

Camacho-Rodríguez J, Macías-Sánchez MD, Cerón-García MC, Alarcón FJ, Molina-Grima E (2017) Microalgae as a potential ingredient for partial fish meal replacement in aquafeeds: nutrient stability under different storage conditions. J Appl Phycol. https://doi.org/10.1007/s10811-017-1281-5

Davidson J, Kenney PB, Barrows FT, Good C, Summerfelt ST (2018) Fillet quality and processing attributes of post-smolt Atlantic salmon, Salmo salar, fed a fishmeal-free diet and a fishmeal-based diet in recirculation aquaculture systems. J World Aquacult Soc 49:183–196. https://doi.org/10.1111/jwas.12452

Davis DA, Gatlin DM (1996) Dietary mineral requirement of fish and marine crustaceans. Rev Fish Sci 4:75–99. https://doi.org/10.1080/10641269609388579

Delaide B, Delhaye G, Dermience M, Gott J, Soyeurt H, Jijakli MH (2017) Plant and fish production performance, nutrient mass balances, energy and water use of the PAFF Box, a small-scale aquaponic system. Aquac Eng 78:130–139

Douglas AE (2010) The symbiotic habit. Princeton University Press, Princeton

Ebeling JM, Timmons MB (2012) Recirculating aquaculture systems. In: Tidwell JH (ed) Aquaculture production systems. Wiley, Hoboken

EC (2009) Regulation (EC) No 1069/2009 of the European parliament and of the council of 21 October 2009 laying down health rules as regards animal by-products and derived products not intended for human consumption and repealing regulation (EC) No 1774/2002 (animal by-products regulation). Off J Eur Union L 300/1. https://doi.org/10.3000/17252555.L_2009.300.eng

Encarnação P (2016) Chapter 5: Functional feed additives in aquaculture feeds. In: Nates SF (ed) Aquafeed formulation. Academic, San Diego, pp 217–237

Endut A, Jusoh A, Ali N, Wan Nik WB (2011) Nutrient removal from aquaculture wastewater by vegetable production in aquaponics recirculation system. Desalinat Water Treat 32:422–430. https://doi.org/10.5004/dwt.2011.2761

EU (2017) Commission Regulation (EU) 2017/893 of 24 May 2017 amending Annexes I and IV to Regulation (EC) No 999/2001 of the European Parliament and of the Council and Annexes X, XIV and XV to Commission Regulation (EU) No 142/2011 as regards the provisions on processed animal protein. Off J Eur Union L138/92. http://data.europa.eu/eli/reg/2017/893/oj

FAO (2014) The State of World Fisheries and Aquaculture. Food and Agricultural Organization, Rome, Italy

FAOSTAT (2015) Fish and fishery products – world apparent consumption statistics based on food balance sheets (1961–)

García-Romero J, Gines R, Izquierdo M, Robaina L (2014a) Marine and freshwater crab meals in diet for red porgy (Pagrus pagrus): effect on fillet fatty acid profile and flesh quality. Aquaculture 420–421:231–239. https://doi.org/10.1016/j.aquaculture.2013.10.035

García-Romero J, Gines R, Vargas R, Izquierdo M, Robaina L (2014b) Marine and freshwater crab meals in diet for red porgy (Pagrus pagrus): Digestibility, ammonia-N excretion, phosphorus and calcium retention. Aquaculture 428–429:158–165. https://doi.org/10.1016/j.aquaculture.2014.02.035

Gatlin DM, Barrows FT, Brown P, Dabrowski K, Gaylord TG, Hardy RW, Herman E, Hu GS, Krogdahl A, Nelson R, Rust M, Sealey W, Skonberg D, Souza EJ, Stone D, Wilson R, Wurtele E (2007) Expanding the utilization of sustainable plant products in aquafeeds; A review. Aquacult Res 38:551–579

Gelineau A, Medale F, Boujard T (1998) Effect of feeding time on postprandial nitrogen excretion and energy expenditure in rainbow trout. J Fish Biol 52:655–664

Gerile S, Pirhonen J (2017) Replacement of fishmeal with corn gluten meal in feeds for juvenile rainbow trout (Oncorhynchus mykiss) does not affect oxygen consumption during forced swimming. Aquaculture 479:616–618. https://doi.org/10.1016/j.aquaculture.2017.07.002

Goddek S, Delaide B, Mankasingh U, Ragnarsdottir KV, Jijakli H, Thorarinsdottir R (2015) Challenges of sustainable and commercial aquaponics. Sustainability 7:4199–4224. https://doi.org/10.3390/su7044199.

Goddek S, Espinal CA, Delaide B, Jijakli MH, Schmautz Z, Wuertz S, Keesman KJ (2016) Navigating towards decoupled Aquaponic systems: a system dynamics design approach. Water 8:303. https://doi.org/10.13140/RG.2.1.3930.0246

Goddek S, Delaide BPL, Joyce A, Wuertz S, Jijakli HM, Grosse A, Eding EH, Bläser I, Reuterg M, Keizer LCP, Morgenstern R, Körner O, Verreth J, Keesman KJ (2018) Nutrient mineralization and organic matter reduction performance of RAS-based sludge in sequential UASB-EGSB reactors. Aquacult Eng 83:10–19. https://doi.org/10.1016/j.aquaeng.2018.07.003

Graber A, Junge R (2009) Aquaponic systems: nutrient recycling from fish wastewater by vegetable production. Desalination 246:147–156

Hardy RW (2010) Utilization of plant proteins in fish diets: effects of global demand and supplies of fishmeal. Review article. Aquacult Res 41:770–776

Henry M, Gasco L, Piccolo G, Fountoulaki E (2015) Review on the use of insects in the diet of farmed fish: past and future. Anim Feed Sci Technol 203:1–22

Hertrampf JW, Piedad-Pascual F (2000) Handbook on ingredients for aquaculture feeds. Kluwer Academic Publishers, Dordrecht. 624 pp

IFFO, The Marine Ingredients Association. http://www.iffo.net

Junge R, König B, Villarroel M, Komives T, Jijakli H (2017) Strategic points in aquaponics. Water 9(3):182. https://doi.org/10.3390/w9030182

Kajimura M, Iwata K, Numata H (2002) Diurnal nitrogen excretion rhythm of the functionally ureogenic gobiid fish Mugilogobius abei. Comp Biochem Physiol B 131:227–239

Kaushik SJ (1980) Influence of the nutritional status on the daily pattern of nitrogen excretion in the carp (Cyprinus carpio L.) and the rainbow trout (Salmo gairdneri R.). Reprod Nut Develop 20:1751–1765

Kaushik S (2017) Aquaculture deals with the production of all kinds of aquatic organisms through human intervention, 2017 meeting. International Council of Academies of Engineering and Technological Sciences (CAETS – http://www.caets.org). Madrid, 14–15 November 2017

Khakyzadeh V, Luque R, Zolfigol MA, Vahidian HR, Salehzadeh H, Moradi V, Soleymani AR, Moosavi-Zare AR, Xu K (2015) Waste to wealth: a sustainable aquaponic system based on residual nitrogen photoconversion. Royal Society of Chemistry 5:3917–3921. https://doi.org/10.1039/C4RA15242E

Kingler D, Naylor R (2012) Searching for Solutions in Aquaculture: Charting a Sustainable Course. Anual Rev Environ Resour 37:247–276

Kloas W, Groß R, Baganz D, Graupner J, Monsees H, Schmidt U, Staaks G, Suhl J, Tschirner M, Wittstock B, Wuertz S, Zikova A, Rennert B (2015) A new concept for aquaponic systems to improve sustainability, increase productivity, and reduce environmental impacts. Aquacult Environ Interact 7:179–192. https://doi.org/10.3354/aei00146

Koch JF, Rawlesb SD, Webster CD, Cummins V, Kobayashic Y, Thompson KR, Gannam AL, Twibell RG, Hyded NM (2016) Optimizing fish meal-free commercial diets for Nile tilapia, Oreochromis niloticus. Aquaculture 452:357–366. https://doi.org/10.1016/j.aquaculture.2015.11.017

Kormas KA, Meziti A, Mente E, Fretzos A (2014) Dietary differences are reflected on the gut prokaryotic community structure of wild and commercially reared sea bream (Sparus aurata). Microbiology open. https://doi.org/10.1002/mbo3.202

Kobayashi M, Msangi S, Batka M, Vannuccini S, Dey MM, Anderson JL (2015) Fish to 2030: the role and opportunity for aquaculture. Aquacult Econ Manage 19:282–300. https://doi.org/10.1080/13657305.2015.994240

Krogdahl A, Penn M, Thorsen J, Refstie S, Bakke AM (2010) Important anti-nutrients in plant feedstuffs for aquaculture: An update on recent findings regarding responses in salmonids. Aquacult Res 41:333–344

Kumar V, Sinha AK, Makkar HPS, De Boeck G, Becker K (2012) Phytate and phytase in fish nutrition. J Anim Physiol Anim Nutr 96:335–364. https://doi.org/10.1111/j.1439-0396.2011.01169.x

Lazzarotto, V., Médale, F., Larroquet, L. & Corraze, G. (2018). Long-term dietary replacement of fishmeal and fish oil in diets for rainbow trout (Oncorhynchus mykiss): Effects on growth, whole body fatty acids and intestinal and hepatic gene expression. PLoS One 13(1) https://doi.org/10.1371/journal.pone.0190730

Le Gouvello, Raphaëla et François Simard (eds) (2017). Durabilité des alimments pour le poisson en aquaculture: Réflexions et recommandations sur les aspects technologiques, économique sociaux et environnementaux. Gland, Suisse: UICN, et Paris, France : Comité français de l’UICN. 296 pp

López-Olmeda JF, Sánchez-Vázquez FJ (2010) Feeding rhythms in fish: from behavioural to molecular approach. In: Kulczykowska E, Popek W. Kapoor BG (eds) Biological clock in fish. CRC Press, Enfield, pp 155–184

Love DC, Fry JP, Genello L, Hill ES, Frederick A, Li X, Semmens K (2014) An International survey of aquaponics practitioners. PLoS One 9(7):e102662. https://doi.org/10.1371/journal.pone.0102662

Love DC, Fry JP, Li X, Hill ES, Genello L, Semmens K, Thompson RE (2015a) Commercial aquaponics production and profitability: findings from an international survey. Aquaculture 435:67–74. https://doi.org/10.1016/j.aquaculture.2014.09.023

Love DC, Uhl MS, Genello L (2015b) Energy and water use of a small-scale raft aquaponics system in Baltimore, Maryland, United States. Aquacult Eng 68:19–27

Lückstädt C (2008) The use of acidifiers in fish nutrition. CAB Rev Perspect Agricult Veterinary Sci Nutr Natur Resour 3:1–8

Makkar HPS, Ankers P (2014) Towards sustainable animal diets: a survey-based study. Anim Feed Sci Technol 198:309–322. https://doi.org/10.1016/j.anifeedsci.2014.09.018

Makkar HPS, Tran G, Heuzé V, Ankers P (2014) State-of-the-art on use of insects as animal feed. Anim Feed Sci Techn 197:1–33. https://doi.org/10.1016/j.anifeedsci.2014.07.008

McClung CR (2006) Plant circadian rhythms. Plant Cell 18:792–803

Mente E, Gannon AT, Nikouli E, Hammer H, Kormas KA (2016) Gut microbial communities associated with the molting stages of the giant freshwater prawn Macrobrachium rosenbergii. Aquaculture 463:181–188

Msangi S, Kobayashi M, Batka M, Vannuccini S, Dey MM, Anderson JL (2013) Fish to 2030: prospects for fisheries and aquaculture. World Bank Report Number 83177-GLB. http://documents.worldbank.org/curated/en/458631468152376668/

Naylor RL, Hardy RW, Bureau DP, Chiu A, Elliott M, Farrell AP, Forster I, Gatlin DM, Goldburg RJ, Hua K, Nichols PD (2009) Feeding aquaculture in an era of finite resources. Proc Natl Acad Sci USA 106:15103–15110

Ng W-K, Koh C-B (2017) The utilization and mode of action of organic acids in the feeds of cultured aquatic animals. Rev Aquacult 9:342–368. https://doi.org/10.1111/raq.12141

Ng W-K, Ang L-P, Liew F-L (2001) An evaluation of mineral supplementation of fish meal-based diets for African catfish. Aquacult Int 9:277–282

NRC. N.R.C (2011) Nutrient requirements of fish and shrimp. The National Academies Press, Washington, District Columbia

Oliva-Teles A (2012) Nutrition and health of aquaculture fish. J Fish Dis 35:83–108. https://doi.org/10.1111/j.1365-2761.2011.01333.x

Pahlow M, Oel PR, Mekonnen MM, Hoekstra AY (2015) Increasing pressure on freshwater resources due to terrestrial feed ingredients for aquaculture production. Sci Total Environ 536:847–857. https://doi.org/10.1016/j.scitotenv.2015.07.124

Palm HW, Seidemann R, Wehofsky S, Knaus U (2014) Significant factors affecting the economic sustainability of closed aquaponic system. Part I: system design, chemo-physical parameters and general aspects. AACL Bioflux 7:20–32

Partanen KH, Mroz Z (1999) Organic acids for performance enhancement in pig diets. Nutr Res Rev 12:117–145

Pearson CJ, Steer BT (1977) Daily changes in nitrate uptake and metabolism in Capsicum annuum. Planta 137(2):107–112. https://doi.org/10.1007/BF00387546

Prabhu PAJ, Schrama JW, Kaushik SJ (2016) Mineral requirements of fish: a systematic review. Rev Aquacult 8:172–219

Rakocy JE, Shultz RC, Bailey DS, Thoman ES (2004) Aquaponic production of tilapia and basil: comparing a batch and staggered cropping system. Acta Hortic 648:63–69. https://doi.org/10.17660/ActaHortic.2004.648.8

Rakocy JE, Masser MP, Losordo TM (2006) Recirculating aquaculture tank production systems: aquaponics- integrating fish and plant culture. Southern Regional Aquaculture Center, pp 1–16

Robaina L, Izquierdo MS, Moyano FJ, Socorro J, Vergara JM, Montero D (1998) Increase of the dietary n-3/n-6 fatty acid ratio and addition of phosphorus improves liver histological alterations induced by feeding diets containing soybean meal to gilthead seabream, Sparus aurata. Aquaculture 161:281–293

Robaina L, Corraze G, Aguirre P, Blanc D, Melcion JP, Kaushik S (1999) Digestibility, postprandial ammonia excretion and selected plasma metabolites in European sea bass (Dicentrarchus labrax) fed pelleted or extruded diets with or without wheat gluten. Aquaculture 179:45–56

Roosta HR, Hamidpour M (2011) Effects of foliar application of some macro- and micro-nutrients on tomato plants in aquaponic and hydroponic systems. Scientia Horticulturae 129:396–402. https://doi.org/10.1016/j.scienta.2011.04.006

Shah MR, Giovanni Antonio Lutzu GA, Alam A, Sarker P, Chowdhury MAK, Parsaeimehr A, Liang Y, Daroch M (2018) Microalgae in aquafeeds for a sustainable aquaculture industry. J Appl Phycol 30:197–213. https://doi.org/10.1007/s10811-017-1234-z

Staples D, Funge-Smith S (2009) Ecosystem approach to fisheries and aquaculture: Implementing the FAO Code of Conduct for Responsible Fisheries. FAO Regional Office for Asia and the Pacific, Bangkok, Thailand. RAP Publication 2009/11, 48 pp

Steingrover E, Ratering P, Siesling J (1986) Daily changes in uptake, reduction and storage of nitrate in spinach grown at low light intensity. Physiol Plantarum 66:555–556

Suomela JP, Tarvainen M, Kallio H, Airaksinen S (2017) Fish oil finishing diet maintains optimal n-3 long-chain fatty acid content in European whitefish (Coregonus lavaretus). Lipids 52:849–855. https://doi.org/10.1007/s11745-017-4290-x

Tacon AGJ (1987) The nutrition and feeding of farmed fish and shrimp - a training manual. Food and Agricultural Organisation of the United Nations, Rome, Italy

Tacon AGJ, Metian M (2008) Global overview on the use of fish meal and fish oil in industrially compounded aquafeeds: trends and future prospects. Aquaculture 285:146–158. https://doi.org/10.1016/j.aquaculture.2008.08.015

Tacon AGJ, Metian M (2015) Feed matters: Satisfying the feed demand of aquaculture. Rev Fish Sci Aquacult 23(1):1–10. https://doi.org/10.1080/23308249.2014.987209

Tacon AGJ, Hasan MR, Metian M (2011) Demand and supply of feed ingredients for farmed fish and crustaceans: trends and prospects. FAO Fisheries and Aquaculture Technical Paper no. 564. FAO, Rome, 87 pp

Terova G, Robaina LE, Izquierdo MS, Cattaneo AG, Molinari S, Bernardini G, Saroglia M (2013) PepT1 mRNA expression levels in sea bream (Sparus aurata) fed different plant protein sources. Springer Plus 2:17. https://doi.org/10.1186/2193-1801-2-17

Thilsted SH, Thorne-Lyman A, Webb P, Bogard JR, Subasinghe R, Phillips MJ, Allison EH (2016) Sustaining healthy diets: The role of capture fisheries and aquaculture for improving nutrition in the post-2015 era. Food Policy 61:126–131. https://doi.org/10.1016/j.foodpol.2016.02.005

Torrecillas S, Robaina L, Caballero MJ, Montero D, Calandra G, Mompel D, Karalazos V, Sadasivam K, Izquierdo M (2017) Combined replacement of fishmeal and fish oil in European sea bass (Dicentrarchus labrax): production performance, tissue composition and liver morphology. Aquaculture 474. https://doi.org/10.1016/j.aquaculture.2017.03.031

Treadwell D, Taber S, Tyson R, Simonne E (2010) HS1163: Foliar-applied micronutrients in aquaponics: s guide to use and sourcing, IFAS Extension. University of Florida

Tveterås S, Asche F, Bellemare MF, Smith MD, Guttormsen AG, Lem A, Lien K, Vannuccini S (2012) Fish is food – the FAO’s fish price index. PLoS ONE 7:e36731

Tyson RV, Treadwell DD, Simonne EH (2011) Opportunities and challenges to sustainability in aquaponic systems. HortTechnology 21:6–13

Van Huis A, Oonincx DGAB (2017) The environmental sustainability of insects as food and feed. A review. Agron Sustain Dev 37:43. https://doi.org/10.1007/s13593-017-0452-8

Villarroel M, Alvariño JMR, Duran JM (2011) Aquaponics: integrating fish feeding rates and ion waste production for strawberry hydroponics. Spanish J Agricult Res 9:537–545

White C (2017) Algae-based aquafeed firms breaking down barriers for fish-free feeds. https://www.seafoodsource.com/news/aquaculture/algae-based-aquafeed-firms-breaking-down-barriers-for-fish-free-feeds

Ytrestøy T, Aas TS, Åsgård T (2015) Utilisation of feed resources in production of Atlantic salmon (Salmo salar) in Norway. Aquaculture 448:365–374. https://doi.org/10.1016/j.aquaculture.2015.06.023

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2019 The Author(s)

About this chapter

Cite this chapter

Robaina, L., Pirhonen, J., Mente, E., Sánchez, J., Goosen, N. (2019). Fish Diets in Aquaponics. In: Goddek, S., Joyce, A., Kotzen, B., Burnell, G.M. (eds) Aquaponics Food Production Systems. Springer, Cham. https://doi.org/10.1007/978-3-030-15943-6_13

Download citation

DOI: https://doi.org/10.1007/978-3-030-15943-6_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-15942-9

Online ISBN: 978-3-030-15943-6

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)