Abstract

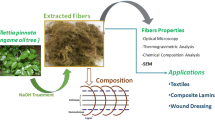

The use of natural lignocellulosic fibers (NLFs) as reinforcement in polymer matrix composites is being considered by many different industries, for instance, the automotive industry where components such as interior panel and cushion seat are being manufactured using NLFs. The piassava fiber is a less characterized NLF when compared to sisal or jute, although the properties displayed by the piassava fiber make them suitable as reinforcement to composite materials . Therefore, this work aimed to present a morphological analysis of the piassava fiber by scanning electron microscopy (SEM) as well as studied the spectroscopy aspects of this fiber by Fourier transform infrared (FTIR ). The SEM analysis revealed differences in their shape and size as well as a rough aspect associated with a great number of protrusions. While the FTIR analysis showed a hydrophilic character of the fibers due to the presence of axil vibration of hydroxyl groups band between 3500 and 3300 cm−1.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Mohanty AK, Misra M, Drzal DL (2002) Sustainable biocomposites from renewable resources: opportunities and challenges in the green material world. J Polym Environ 10:19–26

Monteiro SN, Lopes FPD, Barbosa AP, Bevitori AB, Silva ILA, Costa LL (2011) Natural lignocellulosic fibers as engineering materials–an overview. Metall Mater Trans A 42:2963–2974

Satyanarayana KG, Guimarães JL, Wypych F (2007) Studies on lignocellulosic fibers of Brazil. Part I: source, production, morphology, properties and applications. Compos Part A 38:1694–1709

Monteiro SN et al (2009) Natural-fiber polymer-matrix composites: cheaper, tougher, and environmentally friendly—An overview. JOM 61(1):17–22

Kalia S, Kaith BS, Kaurs I (2011) Cellulose fibers: bio and nano-polymer composites. Springer, New York, USA

Wambua P, Ivens I, Verpoest I (2003) Natural fibers: can they replace glass and fibre reinforced plastics? Compos Sci Technol 63:1259–1264

Holbery J, Houston D (2006) Natural fiber reinforced polymer composite in automobile application. JOM 60:80–88

Pickering K (2008) Properties and performance of natural-fibre composites. CRC Press, Boca Raton, USA

Satyanarayana KG, Arigaza GC, Wypych F (2009) Biodegradable composites based on lignocellulosic fibers–an overview. Progr Polym Sci 34:982–1021

Güven O, Monteiro SN, Moura EAB, Drelich JW (2016) Re-emerging field of lignocellulosic fiber-polymer composites and ionizing radiation technology in their formulation. Polym Rev 56:702–736

Faruk O, Bledzki AK, Fink HP, Sain M (2014) Progress report on natural fiber reinforced composites. Macromol Mater Eng 299:9–26

Nabi Sahed D, Jog JP (1999) Natural fiber polymer composites a review. Adv Polym Technol 18:351–363

Benzait Z, Trabzon L (2018) A review of recent research on materials used in polymer-matrix composites for body armor application. J Compos Mater 52(23):3241–3263

Zah R, Hischier R, Leão AL, Brown I (2007) Curaua fibers in automobile industry – a sustainability assessment. J Clean Prod 15:1032–1040

Alves C, Ferrão PMC, Silva AJ, Reis LG, Freitas M, Rodrigues LB (2010) Ecodesign of automotive components making use of natural jute composites. J Clean Prod 18:313–327

Luz FS, Monteiro SN, Tommasini FJ (2018) Evaluation of dynamic mechanical properties of PALF and coir fiber reinforcing epoxy composites. Mater Res 21:1–7

Senthilkumar K, Saba N, Rajini N, Chandrasekar M, Jawaid M, Siengchin S, Alotman OY (2018) Mechanical properties evaluation of sisal fibre reinforced polymer composites: a review. Constr Build Mater 174(20):713–729

Aquino RCMP, D’Almeida JRM, Monteiro SN (2000) Analysis and characterization of piassava fibers. Acta Microsc 9(A): 3–4

Schuchardt U, Bianchi ML, Gonçalves AR, Curvelo AAS, Biscolla FC, Peres LO (1995) Piassava fibers (Attalea funifera) I–chemical analysis, extraction and reactivity of its lignin. Cellul Chem Technol 29:705–712

Monteiro SN (2008) Properties and structure of Attalea funifera (piassava) fibers for composite reinforcement–a critical discussion. Nat Fibers 6(2):191–203

Nascimento DCO, Ferreira AS, Monteiro SN, Aquino RCMP, Satyanarayana GK (2012) Studies on the characterization of piassava fibers and their epoxy composites. Compos Part A 43:353–362

Garcia Filho FC, Monteiro SN (2018) Piassava fiber as na epoxy matrix composite reinforcement for ballistic armor applications. JOM. https://doi.org/10.1007/s11837-018-3148-x

Mukherjee PS, Satyanarayana KG (1986) An empirical evaluation of structure/property relationships in natural fibers and their fracture behavior. J Mater Sci 21:4162–4168

Khan MA, Idriss Ali KM, Basm SC (1993) IR studies of wood plastic composites. J Appl Polym Sci 49:1547–1551

Da Silva ILA, Bevitori AB, Rohen LA, Margem FM, Braga FO, Monteiro SN (2016) Characterization of fourier transform infrared (FTIR) analysis for natural jute fiber. Mater Sci Forum 869:283–287

Acknowledgements

The authors thank the support of this investigation by the Brazilian agencies: CNPq, FAPERJ, and CAPES.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 The Minerals, Metals & Materials Society

About this paper

Cite this paper

da Costa Garcia Filho, F., da Cruz Demosthenes, L.C., Oliveira, M.S., Pereira, A.C., da Luz, F.S., Monteiro, S.N. (2019). Piassava Fibers: Morphologic and Spectroscopic Aspects. In: Ikhmayies, S., Li, J., Vieira, C., Margem (Deceased), J., de Oliveira Braga, F. (eds) Green Materials Engineering. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-10383-5_14

Download citation

DOI: https://doi.org/10.1007/978-3-030-10383-5_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-10382-8

Online ISBN: 978-3-030-10383-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)