Abstract

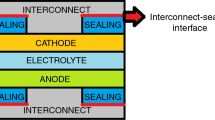

Water reactor safety programs at the Idaho National Engineering Laboratory have required the development of specialized instrumentation. An example is the electrical conductivity-sensitive liquid level transducer developed for use in pressurized-water reactors (PWRs) in which the operation of the sensing probe (Fig. 1) relies upon the passage of current through the water between the center pin of the electrode and its shell such that when water is present the resulting voltage is low, and conversely, when water is absent the voltage is high.1 The transducer’s ceramic seal is a hot-pressed glass ceramic with the following composition (mole percent): SiO2 — 55, BaO — 25, TiO2 — 5.5, CaO — 5.5, As2O5 — 3, Bi2O3 — 2, A12O3 — 2, and CeO2 — 1; its metal housing is Inconel X-750. The ceramic material provides an essential dielectric barrier between the center pin and the outer housing. The operation of the probe as well as the integrity of the PWR environment requires a hermetically-bonded seal between the ceramic and the metal. However, during testing, an increasing number of probe assemblies failed owing to poor glass-to-metal seals as well as void formation within the ceramic. Therefore, a program was initiated to characterize the metallic surface with respect to pre-oxidation treatment and determine optimum conditions for wetting and bonding of the metal by the glass to obtain baseline data relevant to production of acceptable transducer seals.

Work supported by U. S. Department of Energy, under DOE Contract No. DE-AC07-76ID01570.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

W. F. Schwarz, “A Conductivity Liquid Level Detector For the Nuclear Reactor Environment,” IEEE Trans. Nucl. Sci., NS-27, 1, p. 808 (Feb. 1980).

C. S. Giggins and F. S. Pettit, Trans. Metall. Soc. AIME, 245, 2495–2514 (1969).

G. L. Wood, Oxd. Met., 2, pp. 11–57 (1970).

G. E. Wasielewski, “Nickel-Based Superalloy Oxidation,” AFML-TR-67-30 (Jan. 1967).

W. H. Zachariasen, “The Atomic Arrangement in Glass,” J. Amer. Chem. Soc, 54:10 (1932).

B. E. Warren, “Summary of Work on Atomic Arrangement in Glass,” J. Amer. Ceram. Soc, 24:8 (1941).

J. M. Stevels, “New Light on the Structure of Glass,” Phillips Tech. Rev., 22, pp. 300–311 (1968).

J. A. Pask and R. M. Fulrath, “Fundamentals of Glass-to-Metal Bonding: VIII, Nature of Wetting and Adherence,” J. Amer. Ceram. Soc, 45:12, pp. 592–596 (1962).

M. P. Borom and J. A. Pask, “Role of’Adherence Oxides’ in the Development of Chemical Bonding at Glass-Metal Interfaces,” J. Amer. Ceram. Soc, 49:1, pp. 1–6 (1966).

J. J. Brennan and J. A. Pask, “Fundamentals of Glass-to-Metal Bonding: II, Effect of Composition on Glass-Metal Interface Reactions and Adherence,” J. Amer. Ceram. Soc, 56:2, pp. 58–62 (1973).

M. L. Volpe, R. M. Fulrath, and J. A. Pask, “Fundamentals of Glass-to-Metal Bonding: IV, Wettability of Gold and Platinum by Molten Sodium Disilicate,” J. Amer. Ceram. Soc, 42:2, pp. 102–106 (1959).

R. W. Clines, R. M. Fulrath, and J. A. Pask, “Fundamentals of Glass-to-Metal Bonding: V, Wettability of Iron by Molten Sodium Disilicate,” J. Amer. Ceram. Soc, 44:9, pp. 423–428 (1961).

L. G. Hagan and S. F. Ravits, “Fundamentals of Glass-to-Metal Bonding: VI, Reaction Between Metallic Iron and Molten Sodium Disilicate,” J. Amer. Ceram. Soc, 44:9 (1961).

R. B. Adams and J. A. Pask, “Fundamentals of Glass-to-Metal Bonding: III, Silicate Glass Containing Iron Oxide,” J. Amer. Ceram. Soc, 44:9, pp. 430–433 (1961).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1981 Plenum Press, New York

About this chapter

Cite this chapter

Kelsey, P.V., Siegel, W.T., Miley, D.V. (1981). Barium Silicate Glass/Inconel X-750 Interaction. In: Pask, J., Evans, A. (eds) Surfaces and Interfaces in Ceramic and Ceramic — Metal Systems. Materials Science Research, vol 14. Springer, Boston, MA. https://doi.org/10.1007/978-1-4684-3947-2_52

Download citation

DOI: https://doi.org/10.1007/978-1-4684-3947-2_52

Publisher Name: Springer, Boston, MA

Print ISBN: 978-1-4684-3949-6

Online ISBN: 978-1-4684-3947-2

eBook Packages: Springer Book Archive