Abstract

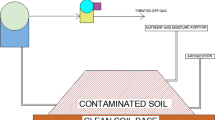

When investigating the treatment of contaminated soils, the application of biotreatment is growing rapidly. Factors influencing this rapid growth include that the bioremediation processes are cost-efficient, safe, and nature-based. In the past, thermal, chemical, and physical treatment methods have failed to eliminate the pollution problem because those methods only shift the environmental pollutants to a new environmental phase such as air and water. Bioremediation technology, which leads to degradation of pollutants, may be a lucrative and environmentally beneficial alternative. Two major groups of bioremediation treatment techniques are used: in situ and ex situ remediation. While in situ remediation is more cost-effective, the thoroughness of this method is less effective than the ex situ remediation. Ex situ remediation is less cost-effective but is a more thorough remediation method. This paper presents biopile design settings and example of calculation for design.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

USEPA (1995) How to evaluate alternative cleanup technologies for underground storage tank sites. Office of Solid Waste and Emergency Response, US Environmental Protection Agency. Publication No. EPA 510-B-95-007, Washington, DC

USEPA (1995) Abstracts of remediation case studies. Office of Solid Waste and Emergency Response, US Environmental Protection Agency. Publication No. EPA 542-R-95-001, Washington, DC

USEPA (1995) A citizen’s guide to soil washing. Office of Solid Waste and Emergency Response, US Environmental Protection Agency. Publication No. EPA 542-F-96-002, Washington, DC

USEPA (1996) In situ soil vapor extraction. Office of Solid Waste and Emergency Response, US Environmental Protection Agency, Washington, DC

USEPA (1996) A citizen’s guide to natural attenuation. Office of Solid Waste and Emergency Response, US Environmental Protection Agency. Publication No. EPA 542-F-96-015, Washington, DC

USEPA (1996) A citizen’s guide to treatment walls. Office of Solid Waste and Emergency Response, US Environmental Protection Agency. Publication No. EPA 542-F-96-016, Washington, DC

USEPA (1996) A citizen’s guide to in situ soil flushing. Office of Solid Waste and Emergency Response, US Environmental Protection Agency. Publication No. EPA 542-F-96-006, Washington, DC

USEPA (1996) A citizen’s guide to in situ thermal desorption. Office of Solid Waste and Emergency Response, US Environmental Protection Agency. Publication No. EPA 542-F-96-005, Washington, DC

USEPA (1996) A citizen’s guide to phytoremediation. Office of Solid Waste and Emergency Response, US Environmental Protection Agency. Publication No. EPA 542-F-96-014, Washington, DC

USEPA (1996) A citizen’s guide to bioremediation. Office of Solid Waste and Emergency Response, US Environmental Protection Agency. Publication No. EPA 542-F-96-007, Washington, DC

USEPA (1998) Soil vapor extraction (SVE). Office of Underground Storage Tank, US Environmental Protection Agency. Publication No. EPA 510-B-95-007, Washington, DC

USEPA (1998) Landfarming. Office of Underground Storage Tank, US Environmental Protection Agency. Publication No. EPA 510-B-95-007, Washington, DC

USEPA (1998) Biosparging. Office of Underground Storage Tank, US Environmental Protection Agency. Publication No. EPA 510-B-95-007, Washington, DC

USEPA (1998) Bioventing. Office of Underground Storage Tank, US Environmental Protection Agency. Publication No. EPA 510-B-95-007, Washington, DC

USEPA (1998) Biopiles. Office of Underground Storage Tank, US Environmental Protection Agency. Publication No. EPA 510-B-95-007, Washington, DC

FRTR (1999) Landfarming. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Passive/reactive treatment walls. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Bioslurping. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) In situ solidification/stabilization. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) In and ex situ solidification/stabilization. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Ground water pumping. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Soil flushing. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) UV oxidation. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Thermal desorption. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Bioventing. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Biopiles. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Phytoremediation. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Aeration. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Slurry phase biological treatment. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) In-well air stripping. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

FRTR (1999) Incineration. Federal Remediation Technologies Roundtable. USEPA, Washington, DC

Reddy KR, Admas JF, Richardson C (1999) Potential technologies for remediation of brownfield. Pract Period Hazard Toxic Radioact Waste Manage 3:61–68

RAAG (2000) Evaluation of risk based corrective action model. Remediation Alternative Assessment Group, Memorial University of Newfoundland, St John’s, NF, Canada

Gan S, Lau EV, Ng HK (2009) Remediation of soils contaminated with polycyclic aromatic hydrocarbons (PAHs). J Hazard Mater 172:532–549

Khan FI, Husain T, Hejazi R (2004) An overview and analysis of site remediation technologies. J Environ Manage 71:95–122

Ellis DE, Hadley PW (2009) Sustainable remediation white paper-integrating sustainable principles, practices, and metrics into remediation projects. 2009 U.S. Sustainable Remediation Forum

Vidali M (2001) Bioremediation. An overview. Pure Appl Chem 73:1163–1172

Kumar A, Bisht B, Joshi V, Dhewa T (2011) Review on bioremediation of polluted environment: a management tool. Int J Environ Sci 1:1079–1093

Coulon F, Whelan MJ, Paton GI, Semple KT, Villa R, Pollard SJT (2010) Multimedia fate of petroleum hydrocarbons in the soil: oil matrix of constructed biopiles. Chemosphere 81:1454–1462

Coulon F, Al Awadi M, Cowie W, Mardlin D, Pollard S, Cunningham C, Risdon G, Arthur P, Semple KT, Paton GI (2010) When is a soil remediated? Comparison of biopiled and windrowed soils contaminated with bunker-fuel in a full-scale trial. Environ Pollut 158:3032–3040

Wu G, Kechavarzi C, Li X, Sui H, Pollard SJT, Coulon F (2013) Influence of mature compost amendment on total and bioavailable polycyclic aromatic hydrocarbons in contaminated soils. Chemosphere 90:2240–2246

von Fahnestock FM, Smith LA, Wickramanayake G, Place MC (1996) Biopile design and construction manual. NFESC, Port Hueneme

Risdon GC, Pollard SJT, Brassington KJ, McEwan JN, Paton GI, Semple KT, Coulon F (2008) Development of an analytical procedure for weathered hydrocarbon contaminated soils within a UK risk-based framework. Anal Chem 80:7090–7096

Coulon F, Brassington K, Bazin R, Linnet P, Thomas K, Mitchell T, Lethbridge G, Smith J, Pollard S (2012) Effect of fertilizer formulation and bioaugmentation on biodegradation and leaching of crude oils and refined products in soils. Environ Technol 33:1879–1893

Goetz J, Brenner RC (2002) Application, performance, and costs of biotreatment technologies for contaminated soils. http://thewatchers.us/EPA/11/2002-not-culturable-in-lab.pdf

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Design Biopile Calculation Example for 286 m3 Gasoline-Contaminated Soil with Low Organic Content

Design Biopile Calculation Example for 286 m3 Gasoline-Contaminated Soil with Low Organic Content

-

1.

Moisture for biopile

Assume:

-

Porosity, φ = 30% and initial saturation, S = 20%

-

Desired water content = 25–85%, use 60%

Therefore:

-

The water needed = 286 × 0.30 × (0.6–0.2) = 34.3 m3 = 34,300 L

-

-

2.

Nutrient requirement for biopile

-

158 kg spill of gasoline (C7H16)

-

Nutrient sources: Ammonium sulphate ((NH4)2SO4); trisodium phosphate (Na3PO4 · 12H2O)

-

MW of gasoline = 7 × 12 + 1 × 16 = 100 g mol−1

-

Moles of gasoline = 158 × 103/100 = 1,580 mol

-

Moles of C = 7 × 1,580 mol = 1.106 × 104 mol

-

Molar ratio C:N:P = 120:10:1

-

Moles of N needed = 10/120 × 1.1 × 104 = 917 mol

-

Moles of ((NH4)2SO4) needed = 917/2 = 458 mol

-

MW of ((NH4)2SO4) = (14 + 4) × 2 + 32 + 4 × 16 = 132 g mol−1

-

Mass of ((NH4)2SO4) needed = 132 × 460 = 6.1 ×104 g = 61 kg

-

By similar calculation:

-

Mass of (Na3PO4 · 12H2O) needed = 35 kg

-

-

-

3.

Oxygen requirement for biopile

$$ {\mathrm{C}}_7{\mathrm{H}}_{16}+22{\mathrm{O}}_2\to 7{\mathrm{C}\mathrm{O}}_2+8{\mathrm{H}}_2\mathrm{O} $$-

1 mol (100 g) gasoline requires 22 mol (16 × 2 × 22 = 704 g) O2

-

Oxygen content of air = 21% by volume = 210,000 ppmv

-

mg L−1 to ppmv:

$$ \begin{array}{l}\mathrm{ppmv}=\frac{\mathrm{mg}}{\mathrm{L}}\times {10}^3\times \frac{1}{{\mathrm{MW}}_{\mathrm{contaminant}}\ \left[\mathrm{g}\ {\mathrm{mol}}^{-1}\right]}\times 8.314\ \left[\frac{\mathrm{L}\;\mathrm{k}\mathrm{P}\mathrm{a}}{\mathrm{mol}\;\mathrm{K}}\right]\\ {}\kern3.5em \times {T}_{\mathrm{air}}\left[K\right]\times \frac{1}{P_{\mathrm{air}}\left[\mathrm{k}\mathrm{P}\mathrm{a}\right]}\end{array} $$

-

Oxygen needed for 158 kg spill of gasoline (≅C7H16)

-

100 g gasoline needs ~704 g O2.

-

158 kg gasoline × 7 = 1,106 kg O2 = 1.1× 106 g O2.

-

Water in pile = 286 m3 × 0.30 × 0.6 = 51.5 m3 = 51,500 L.

-

At saturation at 20°C and 1 atm (101.325 KPa), dissolved oxygen = 9.2 mg L−1.

-

Mass of oxygen in soil moisture = 51,500 L × 9.2 mg L−1 × 0.001 g mg−1 = 473.6 g O2.

-

473 g O2 in soil moisture is much less than 1.1 × 106 g O2 required.

-

At 0.28 g L−1 air, air requirement is 1.1 × 106 g/0.28 g L−1 = 3.93 × 106 L = 3,930 m3.

-

Daily air requirement for a duration of 3 months is 3,930 m3/90 day = 43.7 m3/day.

-

Air void volume in pile = 286 m3 × 0.30 × 0.4 = 34 m3.

-

Need to daily exchange 43.7/34 = 1.3 void volumes to fulfil oxygen requirement (Note: this rate should be compared to passive aeration and check if the latter is sufficient. In the case that it is not, the pump should provide at least twice the air flow as not all the air will be absorbed by the biopile).

Example of calculation of the volumetric composition of a biopile [39]

-

Height: 2.5 m

-

Upper width: 1.24 m

-

Lower width: 5 m

-

Length: 80 m

-

Total volume: 624 m3

-

Total mass: 7.49 × 105 kg

-

Area: ((5 + 1.24) × 2.5)/2 = 7.8 m2

-

Volume: 7.8 × 80 = 624 m3

-

(i)

Total volume: 624 m3

-

(ii)

Total mass: 7.49 × 105 kg = 749 tonnes (assuming a bulk density of 1,200 kg m−3)

-

1.

Water: 80% of field capacity (v/v), field capacity of sandy loam (SL) soil: 20%

-

Water volume = 624 m3 × 0.16 = 99.84 m3

-

-

2.

At 50% porosity, water + air = 50%

-

Air volume = 312–99.84 m3 = 212.16 m3

-

-

3.

2% organic matter, 48% inorganic matter

-

Volume of 2% organic matter = 624 m3 × 0.02 = 12.48 m3

-

Volume of 48% inorganic matter = 624 m3 × 0.48 = 299.52 m3

-

-

4.

TPH t = 0: 80,000 mg oil/kg soil = 0.08 kg oil/kg soil,

-

Density of heavy oil (NAPL): 0.97 g/cm3,

-

NAPL volume = 0.08 kg oil/kg soil = 61.72 m3

-

Assume NAPL shares air volume with air

-

Air volume = 212.16–61.72 m3 = 150.44 m3

-

So overall:

-

Volume of soil = 312 m3

-

Volume of water 100 m3

-

Volume NAPL = 62 m3

-

Volume of air = 150 m3

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this protocol

Cite this protocol

Wu, G., Coulon, F. (2015). Protocol for Biopile Construction Treating Contaminated Soils with Petroleum Hydrocarbons. In: McGenity, T., Timmis, K., Nogales, B. (eds) Hydrocarbon and Lipid Microbiology Protocols. Springer Protocols Handbooks. Springer, Berlin, Heidelberg. https://doi.org/10.1007/8623_2015_149

Download citation

DOI: https://doi.org/10.1007/8623_2015_149

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-53110-5

Online ISBN: 978-3-662-53111-2

eBook Packages: Springer Protocols