Abstract

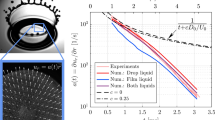

The RDCVD (Rotating Disk Chemical Vapor Deposition) technique is an appropriate method for uniform deposition of grains, such as compound semiconductior materials. The substrate temperature and rotation speed are the major factors, which determine the thickness uniformity of the deposited films. This paper investigates 3D CFD (3 Dimensional Computational Fluid Dynamics) simulation results of flow and heat transfer in a reactor of RDCVD using Fluent. In order to establish the reducibility of buoyancy effect on deposition quality, the chemical transport profile upon the disk heated is examined successfully in 3D domain for different rotating speeds. The resulting vortex flows due the simultaneous buoyance and centrifuge are discussed qualitatively in the 3D virtual system of a RDCVD reactor. 3D CFD is even more effective to describe the internal vortex flows due to the competitive inlet, buoyancy and centrifuge flows, which cannot be realized in the general 2D (2 Dimensional) CFD.

Similar content being viewed by others

References

Razeghi M (1995) The MOCVD Challenge: Volume 2: A Survey of GaInAsP-GaAs for photonic and electronic device applications. IOP Publishing, London

Holloway PH, McGuire, GE (1995) Handbook of compound semiconductors:growth, processing, characterization, and devices. Noyes Publications, New Jersey

Müller G, Métois J-J, Rudolph P (1999) Crystal growth-From fundamentals to technology. Elsevier, London

Olander DR (1967) Surface chemical kinetics and gasphase diffusion in the germanium-iodine reaction, Ind. Eng Chem Fundam. 6:178–188

Breiland WG, Evans GH (1991) Design and verification of nearly ideal flow and heat transfer in a rotating disk chemical vapor deposition reactor, J. Electrochem. Soc. 138:1806–1816

Evand G, Greif R (1987) A numerical model of the flow and heat transfer in a rotating disk chemical vapor deposition reactor, J Heat Transfer. 109:928–937

Kremer DM, Davis RW, Moore EF, Maslar JE, Burgess, Jr. DR, Ehrman SH (2003) An investigation of particle dynamics in a rotating disk chemical vapor deposition Reactor, J. Electrochemical Soc. 150:G127–G139

Mitrovi B, Parekh A, Ramer J, Merai V, Armour EA, Kadinski L, Gurary A (2006) Reactor design optimization based on 3D modeling of nitrides deposition in MOCVD vertical rotating disc reactors, J. Crystal Growth. 289:708–714

Thompson AG (1997) MOCVD technology for semiconductors, Materials Letters. 30:255–263

Hwang JW, Yoon DY, Choi KH, Kim Y, Kim LH (2008) 3D CFD analysis of the hydrogen releases and dispersion around storage facilities, Korean J. Chem Eng. 25:217–222

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, JH., Yoon, DY. 3D CFD for chemical transport profiles in a rotating disk CVD reactor. 3D Res 1, 5 (2010). https://doi.org/10.1007/3DRes.02(2010)05

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/3DRes.02(2010)05