Abstract

The dynamic increase factor (DIF) for the dynamic compressive and tensile strength of concrete-like brittle materials subjected to impact and blast loading has been a broad subject of extensive investigation and debate for many years. The necessity of studying the dynamic behaviour of concrete-like brittle material is increasing daily for the analysis and design of building structures for safety and security purposes. In this context, this paper reviews and summarizes the dynamic increase factor obtained from experimental and numerical studies under compression and tension for their resistance under a high loading rate. Numerous researchers have conducted Split Hopkinson Pressure Bar (SHPB) experiments on concrete, mortar, and composite materials. They have proposed several empirical relationships between the strain rate and Dynamic Increase Factor (DIF). These DIF values, suitable for both compression and tension, have gained extensive acceptance in authoritative design guidelines and model codes for numerical simulation studies. Most of the DIF models followed the power low variation function, linear function, and polynomial function as a function of strain rate, but the trends of DIF models significantly varied from each other based on the experimental results. A few DIF models are available considering the effect of end friction confinement, lateral inertia confinement, porosity, specimen dimensions, and fiber content, as these factors also significantly influence the dynamic strength of materials. Additionally, the value suggested for the transition strain rate significantly varied in compression as well as in tension based on the experimental study. The transition strain rate for dynamic strength in compression is predominantly observed to be above 10 s–1, whereas, for tensile strength, the transition strain rate is approximately 1 s–1, described that the tensile behaviour of concrete is more sensitive to the strain rate.

Similar content being viewed by others

REFERENCES

U. S. Lindholm, “High strain testing, part I: measurement of mechanical properties,” in Techniques of Metals Research, Ed by. R. F. Bunshah, Vol. 5 (Wiley Interscience, New York, 1971), pp. 199–271.

W. W. Chen and B. Song, “Conventional Kolsky bars,” in Split Hopkinson (Kolsky) Bar. Mechanical Engineering Series (Springer, Boston, 2010), pp. 1–35. https://doi.org/10.1007/978-1-4419-7982-7_1

B. Song, K. Connelly, J. Korellis, et al., “Improved Kolsky-bar design for mechanical characterization of materials at high strain rates,” Meas. Sci. Technol. 20 (11), 115701 (2009). https://doi.org/10.1088/0957-0233/20/11/115701

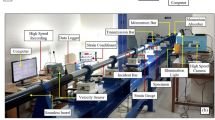

M. M. Khan and M. A. Iqbal, “Design, development, and calibration of split Hopkinson pressure bar system for Dynamic material characterization of concrete,” Int. J. Protect. Struct. (2023). https://doi.org/10.1177/20414196231155947

C. A. Ross, J. W. Tedesco, and S. T. Kuennen, “Effects of strain rate on concrete strength,” Mater. J. 92 (1), 37–47 (1995). https://doi.org/10.14359/1175

Q. M. Li, and H. Meng, “About the dynamic strength enhancement of concrete-like materials in a split Hopkinson pressure bar test,” Int. J. Solids Struct. 40 (2), 343–360 (2003). https://doi.org/10.1016/S0020-7683(02)00526-7

T. J. Holmquist and G. R. Johnson, “A computational constitutive model for glass subjected to large strains, high strain rates and high pressures,” ASME J. Appl. Mech. 78 (5), 051003 (2011). https://doi.org/10.1115/1.4004326

W. Riedel, Doctoral Dissertation in Engineering (Fraunhofer Institut für Kurzzeitdynamik, Ernst-Mach-Institut, Freiburg, 2000).

W. Riedel, N. Kawai, and K. I. Kondo, “Numerical assessment for impact strength measurements in concrete materials,” Int. J. Impact Eng. 36 (2), 283–293 (2009). https://doi.org/10.1016/j.ijimpeng.2007.12.012

D. C. Drucker and W. Prager, “Soil mechanics and plastic analysis for limit design,” Quart. Appl. Math. 10 (2), 157–165 (1952).

T. Jankowiak and T. Lodygowski, “Identification of parameters of concrete damage plasticity constitutive model,” Found. Civil Environ. Eng. 6 (1), 53–69 (2005).

M. A. Kamran and Iqbal, “A new material model for concrete subjected to high rate of loading,” Int. J. Impact Eng. (2023). https://doi.org/10.1016/j.ijimpeng.2023.104673

X. Chen, S. Wu, and J. Zhou, “Experimental and modeling study of dynamic mechanical properties of cement paste, mortar and concrete,” Constr. Build. Mater. 47, 419–430 (2013). https://doi.org/10.1016/j.conbuildmat.2013.05.063

S. Lee, K. M. Kim, J. Park, and J. Y. Cho, “Pure rate effect on the concrete compressive strength in the split Hopkinson pressure bar test,” Int. J. Impact Eng. 113, 191–202 (2018). https://doi.org/10.1016/j.ijimpeng.2017.11.015

M. K. Khan, M. A. Iqbal, V. Bratov, et al., “An investigation of the ballistic performance of independent ceramic target,” Thin-Walled Struct. 154, 106784 (2020). https://doi.org/10.1016/j.tws.2020.106784

M. K. Khan and M. A. Iqbal, “Failure and fragmentation of ceramic target with varying geometric configuration under ballistic impact,” Ceram. Int. 48 (18), 26147–26167 (2022). https://doi.org/10.1016/j.ceramint.2022.05.297

Y. B. Guo, G. F. Gao, L. Jing, and V. P. W. Shim, “Response of high-strength concrete to dynamic compressive loading,” Int. J. Impact Eng. 108, 114–135 (2017). https://doi.org/10.1016/j.ijimpeng.2017.04.015

E. A. Flores-Johnson and Q. M. Li, “Structural effects on compressive strength enhancement of concrete-like materials in a split Hopkinson pressure bar test,” Int. J. Impact Eng. 109, 408–418 (2017). https://doi.org/10.1016/j.ijimpeng.2017.08.003

Comite Euro-International du Beton, CEB-FIP Model Code 1990: Design Code (Thomas Telford, London, 1993).

Y. Hao, H. Hao, G. P. Jiang, and Y. Zhou, “Experimental confirmation of some factors influencing dynamic concrete compressive strengths in high-speed impact tests,” Cem. Concr. Res. 52, 63–70 (2013). https://doi.org/10.1016/j.cemconres.2013.05.008

Code Requirements for Nuclear Safety-Related Concrete Structures and Commentary, Model Code ACI 349-13 (ACI Committee, 2014).

Structures to Resist the Effects of Accidental Explosions, UFC 3-340-02, Unified Facilities Criteria (UFC) (United States Department of Defense, 2008).

Model Code, 2010, First Complete Draft, Vol. 1 (FIB, 2010).

J. Hopkinson, “On the rupture of iron wire by a blow,” Proc. Literary Phil. Soc. Manch. 1, 40–45 (1872).

H. Kolsky, “An investigation of the mechanical properties of materials at very high rates of loading,” Proc. Phys. Soc. B 62 (11), 676 (1949). https://doi.org/10.1088/0370-1301/62/11/302

B. Song, K. Connelly, J. Korellis, et al., “Improvement in Kolsky-bar design for mechanical characterization of materials at high strain rates,” Meas. Sci. Technol. 20, 115701 (2009). https://doi.org/10.1088/0957-0233/20/11/115701

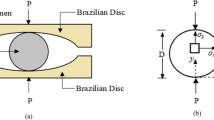

J. W. Tedesco and C. A. Ross, “Experimental and numerical analysis of high strain rate splitting-tensile tests,” Mater. J. 90 (2), 162–169 (1993). https://doi.org/10.14359/4013

J. W. Tedesco, J. C. Powell, C. A. Ross, and M. L. Hughes, “A strain-rate-dependent concrete material model for ADINA,” Comp. Struct. 64 (5–6), 1053–1067 (1997). https://doi.org/10.1016/S0045-7949(97)00018-7

H. Schuler, C. Mayrhofer, and K. Thoma, “Spall experiments for the measurement of the tensile strength and fracture energy of concrete at high strain rates,” Int. J. Impact Eng. 32 (10), 1635-1650 (2006). https://doi.org/10.1016/j.ijimpeng.2005.01.010

K. Fujikake, K. Uebayashi, T. Ohno, et al., “Formulation of an orthotropic constitutive model for concrete materials under high strain rates and tri-axial stress states,” J. Mat. Conc. Struct. Pave. 50 (669), 109–23 (2001). https://doi.org/10.2208/jscej.2001.669_109

T. Hartmann, A. Pietzsch, and N. Gebbeken, “A hydrocode material model for concrete,” Int. J. Protect. Struct. 1 (4), 443–68 (2010). https://doi.org/10.1260/2041-4196.1.4.443

J. W. Tedesco and C. A. Ross, “Strain-rate-dependent constitutive equations for concrete,” ASME J. Pressure Vessel Technol. 120 (4), 398–405 (1998). https://doi.org/10.1115/1.2842350

Y. Guo, G. Gao, L. Jing, and V. Shim, “Response of high-strength concrete to dynamic compressive loading,” Int. J. Impact Eng. 108, 114–135 (2017). https://doi.org/10.1016/j.ijimpeng.2017.04.015

T. Ngo, P. Mendis, and T. Krauthammer, “Behavior of ultrahigh-strength prestressed concrete panels subjected to blast loading,” J. Struct. Eng. 133, 1582–1590 (2007). https://doi.org/10.1061/(ASCE)0733-9445(2007)133:11(1582)

Y. Al-Salloum, T. Almusallam, S. M. Ibrahim, et al. “Rate dependent behavior and modeling of concrete based on SHPB experiments,” Cem. Concr. Compos. 55, 34–44 (2015). https://doi.org/10.1016/j.cemconcomp.2014.07.011

Y. Lu and K. Xu, “Modelling of dynamic behaviour of concrete materials under blast loading,” Int. J. Solids Struct. 41(1), 131–43 (2004). https://doi.org/10.1016/j.ijsolstr.2003.09.019

D. L. Grote, S. W. Park, and M. Zhou, “Dynamic behavior of concrete at high strain rates and pressures: I. experimental characterization,” Int. J. Impact Eng. 25 (9), 869–886 (2001). https://doi.org/10.1016/S0734-743X(01)00020-3

Q. M. Li and H. Meng, “About the dynamic strength enhancement of concrete-like materials in a split Hopkinson pressure bar test,” Int. J. Solids Struct. 40 (2), 343–360 (2003). https://doi.org/10.1016/S0020-7683(02)00526-7

X. Q. Zhou and H. Hao, “Modeling of compressive behaviour of concrete-like materials at high strain rate,” Int. J. Solids Struct. 45 (17), 4648–4661 (2008). https://doi.org/10.1016/S0020-7683(02)00526-7

M. Katayama, M. Itoh, S. Tamura, et al., “Numerical analysis method for the RC and geological structures subjected to extreme loading by energetic materials,” Int. J. Impact Eng. 34, 1546–1561 (2007).

Y. Hao, H. Hao, and Z. X. Li, “Influence of end friction confinement on impact tests of concrete material at high strain rate,” Int. J. Impact Eng. 60, 82–106 (2013). https://doi.org/10.1016/j.ijimpeng.2013.04.008

Y.F. Hao and H. Hao, “Numerical evaluation of the influence of aggregates on concrete compressive strength at high strain rate,” Int. J. Protect. Struct. 2, 177–206 (2011). https://doi.org/10.1260/2041-4196.2.2.177

Y.F. Hao, H. Hao, G.P. Jiang, and Y. Zhou, “Experimental confirmation of some factors influencing dynamic concrete compressive strengths in high-speed impact tests,” Cem. Concr. Res. 52, 63–70 (2013). https://doi.org/10.1016/j.cemconres.2013.05.008

S. Ahmad, P. Bhargava, A. Chourasia, and A. Usmani, “Effect of elevated temperatures on the shear-friction behaviour of concrete: Experimental and analytical study,” Eng. Struct. 225, 111305 (2020). https://doi.org/10.1016/j.engstruct.2020.111305

S. Ahmad, P. Bhargava, and N. M. Bhandari, “Evaluation of shear transfer capacity of reinforced concrete exposed to fire,” IOP Conf. Ser.: Earth Environ. Sci. 140 012146 (2018). https://doi.org/10.1088/1755-1315/140/1/012146

S. Ahmad, P. Bhargava, and A. Chourasia, “Direct shear failure in concrete joints exposed to elevated temperatures,” Struct. 27, 1851–1859 (2020). https://doi.org/10.1016/j.istruc.2020.07.074

S. Ahmad, P. Bhargava, A. Chourasia, and M. Ju, “Residual shear strength of reinforced concrete slender beams without transverse reinforcement after elevated temperatures,” Eng. Struct. 237, 112163 (2021). https://doi.org/10.1016/j.engstruct.2021.112163

Fib Model Code for Concrete Structures 2010 (FIB, Lausanne, 2013).

L. J. Malvar and C. A. Ross, “Review of strain rate effects for concrete in tension,” ACI Mater. J. 95, 735–739 (1998).

P. Soroushian, K. B. Choi, and A. Alhamad, “Dynamic constitutive behavior of concrete,” Int. J. Proc. 83 (2), 251–259 (1986).

K. Komlos, “Investigation of rheological properties of concrete in uniaxial tension,” Mater. Test. 12 (9), 300–304 (1970). https://doi.org/10.1515/mt-1970-120902

S. Xiao, H. Li, and P. J. M. Monteiro, “Influence of strain rates and load histories on the tensile damage behaviour of concrete,” Mag. Concr. Res. 62 (12), 887–894 (2010). https://doi.org/10.1680/macr.2010.62.12.887

S. Panchal, S. Sharma, M. M. Khan, et al., “Effect of glass reinforcement and glass powder on the characteristics of concrete,” Int. J. Civil Eng. Technol. 8 (3), 637–647 (2017).

Kamran and M. A. Iqbal, “The ballistic evaluation of plain, reinforced and reinforced–prestressed concrete,” Thin-Walled Struct. 179, 109707 (2022). https://doi.org/10.1016/j.tws.2022.109707

ACKNOWLEDGMENTS

The authors express their gratitude to the Indian Institute of Technology Roorkee, India, and the financial assistantship from the Ministry of Human Resource and Development (MHRD), Government of India.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

CONFLICT OF INTEREST

The authors of this work declare that they have no conflicts of interest.

DECLARATION

All authors have been confirming their approval for publication and declare no conflicts of interest among them.

Additional information

Publisher’s Note.

Allerton Press remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Khan, M.M., Iqbal, M.A. Dynamic Increase Factor of Concrete Subjected to Compression and Tension by using Split Hopkinson Pressure Bar Setup: Overview. Mech. Solids 58, 2115–2131 (2023). https://doi.org/10.3103/S0025654423601064

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0025654423601064