Abstract

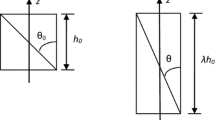

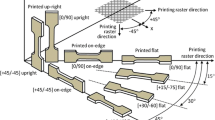

Polymer chain orientation is crucial to understanding the polymer dynamics at interfaces formed during thermoplastic material extrusion additive manufacturing. The flow field and rapid cooling produced during material extrusion can result in chains which are oriented and stretched, which has implications for interdiffusion and crystallization. Polarized Raman spectroscopy offers a non-destructive and surface sensitive method to quantify chain orientation. To study orientation and alignment of chains in 3D printed polycarbonate filaments, we used a combination of polarized Raman spectroscopy and birefringence (\(\Delta n\)) measurements. By changing the orientation of the sample with respect to polarization of incident radiation, we probe changes in the ratio between orientation-dependent vibration modes and orientation-independent modes. We used principal component analysis (PCA) and partial least squares (PLS) regression to develop correlations for birefringence and Raman measurements in samples that were pulled at different draw ratios (DRs). PCA was used to differentiate between orientation-dependent and orientation-independent modes, while PLS regression was used to calculate birefringence from Raman measurements of 3D printed samples. Birefringence measurements were compared to the polycarbonate intrinsic birefringence of 0.2, to estimate the degree of orientation. We find that measured values of birefringence underestimate orientation compared to Raman measurements.

GraphicAbstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Notes

Material extrusion is the ASTM definition for this process; however, it is also known as fused deposition modeling (FDM)® or fused filament fabrication (FFF).

Certain commercial equipment, instruments, or materials are identified in this paper to specify the experimental procedure adequately. Such identification is not intended to imply recommendation or endorsement by the National Institute of Standards and Technology, nor is it intended to imply that the materials or equipment identified are necessarily the best available for the purpose.

References

J.P. Davim, Machining: Fundamentals and Recent Advances, Springer, London, ISBN 978-1-84800-212-8, (2008)

J.E. Seppala, S.H. Han, K.E. Hillgartner, C.S. Davis, K.B. Migler, Weld formation during material extrusion additive manufacturing. Soft Matter 13, 6761–6769 (2017)

T.J. Coogan, D.O. Kazmer, Healing simulation for bond strength prediction of FDM. Rapid Prototyp J 23, 11 (2017)

C.S. Davis, K.E. Hillgartner, S.H. Han, J.E. Seppala, Mechanical strength of welding zones produced by polymer extrusion additive manufacturing. Addit Manuf 16, 162–166 (2017)

L. Fang, Y. Yan, O. Agarwal, J.E. Seppala, K.J. Hemker, S.H. Kang, Processing-structure-property relationships of bisphenol-A-polycarbonate samples prepared by Fused Filament Fabrication. Addit Manuf 35, 101285 (2020)

K.R. Hart, E.D. Wetzel, Fracture behavior of additively manufactured acrylonitrile butadiene styrene (ABS) materials. Eng Fract Mech 177, 1–13 (2017)

C. McIlroy, P. Olmsted, Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 123, 376–391 (2017a)

A. Costanzo, R. Spotorno, M.V. Candal, M.. M.. Fernández, A.. J.. Müller, G.. R.. S, D. Cavallo, C. McIlroy, Residual alignment and its effect on weld strength in material-extrusion 3D-printing of polylactic acid. Addit Manuf 36, 101415 (2020)

I.M. Ward, Structure and Properties of Oriented Polymers (Springer, Berlin, 1975)

K. Kojio, T. Kajiwara, S. Yamamoto, A. Fujimoto, K. Fukada, C. Nagano, S. Masuda, C.-H. Cheng, S. Nozaki, K. Kamitani, A. Takahara, Direct visualization of the molecular orientation and microstructure of glassy transparent polymers after the scratch test based on optical microscopy and X-ray scattering. Polymer 181, 121773 (2019)

H.J. Biangardi, Determination of the orientation distribution function of amorphous polymers by wide angle X-ray scattering measurements. Makromol Chem 183, 1785–1802 (1982)

G. Voyiatzis, G. Petekidis, D. Vlassopoulos, E.I. Kamitsos, A. Bruggeman, Molecular orientation in polyester films using polarized laser Raman and Fourier transform infrared spectroscopies and X-ray diffraction. Macromolecules 29(6), 2244–2252 (1996)

R. Wimbercer-Fried, J.G.D. Bruin, Birefringence in polycarbonate: molecular orientation induced by cooling stresses. I. Free quenching. J Polym Sci 31, 1041–1049 (1993)

C.W. Lantman, J.F. Tassin, L. Monnerie, L.J. Fetters, E. Helfand, D.S. Pearson, Fourier transform infrared dichroism study of orientation relaxation using isotopically labeled polystyrene stars. Macromolecules 22, 1184–1188 (1989)

C.Y. Lang, S. Krimm, Infrared spectra of high polymers. J Mol Spectrosc 3, 554–574 (1959)

S. Krimm, Infrared spectra of high polymers, in Advances in Polymer Science, vol. 2, ed. by T. Krimm (Springer, Berlin, 1960), pp. 51–172

J. Guèvremont, A. Ajji, K.C. Cole, M.M. Dumoulin, Orientation and conformation in poly(ethylene terephthalate) with low draw ratios as characterized by specular reflection infra-red spectroscopy. Polymer 36(17), 3385–3392 (1995)

N. Everall, P. Tayler, J.M. Chalmers, D. MacKerron, R. Ferwerda, J.H. van der Maas, Study of density and orientation in poly(ethylene terephthalate) using Fourier transform Raman spectrocopy and multivariate data analysis. Polymer 35(15), 3184–3192 (1994)

S. Natarajan, S. Michielsen, Determination of density and birefringence of poly(ethylene terephthalate) fibers using Raman microscopy. J Appl Polym Sci 73, 943–952 (1999)

M. Pigeon, R.E. Prudhomme, M. Pézolet, Characterization of molecular orientation in polyethylene by Raman spectroscopy. Macromolecules 24, 5687–5694 (1991)

D. Purvis, D.I. Bower, A study of molecular orientation in poly(methyl methacrylate) by means of laser-Raman spectroscopy. Polymer 15, 645–654 (1974)

D.I. Bower, Investigation of molecular orientation distributions by polarized Raman scattering and polarized fluorescence. J Polym Sci 10, 2135–2153 (1972)

S. Yang, S. Michielsen, Orientation distribution functions obtained via polarized Raman spectroscopy of poly(ethylene terephthalate) fibers. Macromolecules 36(17), 6484–6492 (2003)

A. Soto, G. A. Voyiatzis, Molecular orientation of poly(ethylene naphthalate)\(\backslash\) poly(ethylene terephthalate) copolymers utilizing polarized Raman spectra. Macromolecules 2002, 35, 2095–2104 35 (6) (2002) 2095–2104

J. Pruvis, D.I. Bower, Molecular orientation in poly(ethylene terephthalate) by means of laser-Raman spectroscopy. J Polym Sci 14, 1461–1484 (1976)

M.J. Citra, D.B. Chase, R.M. Ikeda, K.H. Gardner, Molecular orientation of high-density polyethylene fibers characterized by polarized Raman spectroscopy. Macromolecules 28(11), 4007–4012 (1995)

M. Takeshima, N. Funakoshi, Molecular orientation distribution in injection-molded polycarbonate discs. J Appl Polym Sci 32, 3457–3468 (1986)

M.A.G. Cunha, M.O. Robbins, Effect of flow-induced molecular alignment on welding and strength of polymer interfaces. Macromolecules 53(19), 8417–8427 (2020)

J. Bent, L.R. Hutchings, R.W. Richards, T. Gough, R. Spares, P.D. Coates, I. Grillo, O.G. Harlen, D.J. Read, R.S. Graham, A.E. Likhtman, D.J. Groves, T.M. Nicholson, T.C.B. McLeish, Neutron-mapping polymer flow: scattering, flow visualization, and molecular theory. Science 301(5640), 1691–1695 (2003)

R.S. Graham, J. Bent, L.R. Hutchings, R.W. Richards, D.J. Groves, J. Embery, T.M. Nicholson, T.C.B. McLeish, A.E. Likhtman, O.G. Harlen, D.J. Read, T. Gough, R. Spares, P.D. Coates, I. Grillo, Measuring and predicting the dynamics of linear monodisperse entangled polymers in rapid flow through an abrupt contraction. A small angle neutron scattering study. Macromolecules 39(7), 2700–2709 (2006)

T.C. Damen, S.P.S. Porto, B. Tell, Raman effect in zinc oxide. Phys Rev 142, 570–574 (1966)

V. Resta, G. Quarta, M. Lomascolo, L. Maruccio, L. Calcagnile, Raman and photoluminescence spectroscopy of polycarbonate matrices irradiated with different energy \(^{28}\)Si\(^{+}\) ions. Vacuum 116, 82–89 (2015)

M. Pietralla, T. Pieper, The problem of intrinsic birefringence and chain conformation in polycarbonate from bisphenol-A. Colloid Polym Sci 268(9), 797–805 (1990)

M.S. Wu, Intrinsic birefringence of amorphous poly(bisphenol-A carbonate). J Appl Polym Sci 32, 3263–3275 (1986)

T.C. O’Connor, A. Hopkins, M.O. Robbins, Stress relaxation in highly oriented melts of entangled polymers. Macromolecules 52(8540–8550), 22 (2019)

A.E. Likhtman, T.C.B. McLeish, Quantitative theory for linear dynamics of linear entangled polymers. Macromolecules 35(16), 6332–6343 (2002)

V.A.H. Boudara, D.J. Read, J. Ramírez, Reptate rheology software: toolkit for the analysis of theories and experiments. J Rheol 64(3), 709–722 (2020)

J.E. Seppala, K.D. Migler, Infrared thermography of welding zones produced by polymer extrusion additive manufacturing. Addit Manuf 12(Part A), 71–76 (2016)

C. McIlroy, P.D. Olmsted, Deformation of an amorphous polymer during the fused-filament-fabrication method for additive manufacturing. J Rheol 61, 379–397 (2017b)

Acknowledgments

The authors would like to thank Marco A. G. Cunha and the late Mark O. Robbins for their invaluable discussions on relaxation processes during flow. This work was supported by the National Institute of Standards and Technology (NIST) Scientific and Technical Research and Services (STRS) and by the National Science Foundation (NSF) under Grant Number NSF DMREF-90069795.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Official contribution of the National Institute of Standards and Technology; not subject to copyright in the United States.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hassan, N.M., Migler, K.B., Hight Walker, A.R. et al. Comparing polarized Raman spectroscopy and birefringence as probes of molecular scale alignment in 3D printed thermoplastics. MRS Communications 11, 157–167 (2021). https://doi.org/10.1557/s43579-021-00025-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-021-00025-z