Abstract

Directionally solidified oxide eutectic ceramic (DSOEC) has been one of the focuses of ceramic materials because of its excellent mechanical properties and oxidation resistance at ultra-high temperature (above 1600 ℃). Al2O3/GdAlO3/ZrO2 ternary DSOEC was prepared with induction heating zone melting method, of which microstructure and mechanical properties’ involution with the growth rate was revealed. As the growth rate increased, the microstructure of Al2O3/GdAlO3/ZrO2 DSOEC became into a complex regular structure from an irregular network structure, and the eutectic spacing decreased continuously. Its fracture toughness increased first from 4.75 to 6.55 MPa m1/2 and then decreased to 5.48 MPa m1/2, while its hardness increased continuously from 12.20 to 15.56 GPa. The third component ZrO2 made GdAlO3 phase microstructure in the binary eutectic Al2O3/GdAlO3 from a complex regular structure transformed into an irregular network one in the ternary Al2O3/GdAlO3/ZrO2 for the low growth rate, while from the regular layered microstructure to the regular triangular one in the ternary eutectic for the high growth rate, ZrO2 phase also increased the eutectic spacing, improved the fracture toughness. The fracture toughness at room temperature (4.75–6.55 MPa m1/2) of Al2O3/GdAlO3/ZrO2 ternary DSOEC was much higher than that of Al2O3/GdAlO3 binary DSOEC (1.47–3.24 MPa m1/2).

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated during and analyzed during the current study are available from the corresponding author on reasonable request.

References

O. Stanners, J. Russell, S. John et al., Powder interlayer bonding of nickel-based superalloys with dissimilar chemistries. Materials 14(8), 2029 (2021)

E.J. Pickering, K.A. Christofidou, H.J. Stone et al., On the design and feasibility of tantalum-base superalloys. J. Alloy. Compd. 804, 314–321 (2019)

J. Zhang, H. Chen, G. Xiao et al., Effects of Si3N4 and WC on the oxidation resistance of ZrB2/SiC ceramic tool materials. Ceram. Int. 48(6), 8097–8103 (2022)

S. Miladinović, B. Stojanović, S. Gajević et al., Hypereutectic aluminum alloys and composites: a review. Silicon (2022). https://doi.org/10.1007/s12633-022-02216-2

X. Wang, Y.J. Zhong, D. Wang, Q.G. Xian, J.Y. Wang, L.H. Lou, J. Zhang, Fracture morphology and mechanism of a directionally solidified Al2O3/Y3Al5O12 eutectic single crystal. Scr. Mater. 135, 46–49 (2017)

B. Liu, Y. Wang, C. Li et al., Research on the thermal shock simulation of the super highspeed aircraft. Mech. Adv. Mater. Struct. 30(9), 1889–1896 (2022)

R. Valle, L. Carroz, M.-H. Ritti, M. Podgorski, M. Parlier, Mechanical testing of directionally solidified eutectic ceramics (DSECs): specific problems and limitations. J. Mater. Sci. 52, 10047–10061 (2017)

C.Y. Song, S.H. Wang, J.C. Liu, S.Y. Zhai, Microstructure and mechanical properties of Al2O3/Er3Al5O12 binary eutectic ceramic prepared by bridgman method. Materials 11(4), 534 (2018)

H. Su, Z. Shen, Q. Ren et al., Evolutions of rod diameter, molten zone and temperature gradient of oxide eutectic ceramics during laser floating zone melting. Ceram. Int. 46(11), 18750–18757 (2020)

D.Y. Park, J.M. Yang, Effect of the microstructure on the mechanical properties of a directionally solidified Al2O3-Y3Al5O12 eutectic fiber. J. Mater. Sci. 36(23), 5593–5601 (2001)

O. Benamara, K. Lebbou, Orientations and seed type effect on Al2O3-YAG-ZrO2 eutectic microstructure solidified from the melt by the micro-pulling down technique. J. Eur. Ceram. Soc. 41(11), 5613–5623 (2021)

S. Wang, Z. Chu, J. Liu, Microstructure and mechanical properties of directionally solidified Al2O3/GdAlO3 eutectic ceramic prepared with horizontal high-frequency zone melting. Ceram. Int. 45(8), 10279–10285 (2019)

H. Su, E. Wang, Q. Ren et al., Microstructure tailoring and thermal stability of directionally solidified Al2O3/GdAlO3 binary eutectic ceramics by laser floating zone melting. Ceram. Int. 44(7), 7908–7916 (2018)

Y. Waku, H. Ohtsubo, N. Nakagawa et al., High temperature characteristics of unidirectionally solidified Al2O3/GAP eutectic composites with a novel microstructure. Mater. Sci. Forum 706–709, 246–251 (2012)

L. Mazerolles, L. Perriere, S. Lartigue-Korinek et al., Microstructures, crystallography of interfaces, and creep behavior of melt-growth composites. J. Eur. Ceram. Soc. 28(12), 2301–2308 (2008)

H. Su, J. Zhang, J. Yu et al., Directional solidification and microstructural development of Al2 O3/GdAlO3, eutectic ceramic in situ, composite under rapid growth conditions. J. Alloy. Compd. 509(12), 4420–4425 (2011)

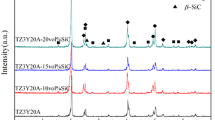

W. Ma, J. Zhang, H. Su et al., Microstructure transformation from irregular eutectic to complex regular eutectic in directionally solidified Al2O3/GdAlO3/ZrO2 ceramics by laser floating zone melting. J. Eur. Ceram. Soc. 36(6), 1447–1454 (2016)

K. Upadhyay, R. Kumar Tamrakar, Enhancement in photoluminescence behaviour of GdAlO3 Eu3+ phosphor by alkali metal codoping. Nano-Struct. Nano-Objects 19, 100357 (2019)

Q. Chen, J. Li, W. Wang, Synthesis and luminescence properties of Tb3+/Eu3+ co-doped GdAlO3 phosphors with enhanced red emission. J. Rare Earths 36(9), 924–930 (2018)

M.M. Gul, K.S. Ahmad, A.G. Thomas et al., Remarkable energy storage and photocatalytic remediation potential of novel graphene oxide loaded bi-metal sulphide Ba4Fe2S6-GO nanocomposite thin film. Opt. Mater. 138, 113682 (2023)

M.M. Gul, K.S. Ahmad, Y.T. Alharbi et al., Exploring the dual functionality of Er2S3: Al2S3: NiS2 thin film as supercapacitor electrode and photocatalyst for efficient energy storage and pollutant degradation. J. Mater. Res. 38(16), 3995–4008 (2023)

A. Henniche, J. Ouyang, Y. Ma et al., Microstructure, mechanical and thermo-physical properties of hot-pressed Al2O3–GdAlO3–ZrO2 ceramics with eutectic composition. Prog. Nat. Sci.: Mater. Int. 27(4), 491–497 (2017)

H. Liu, H. Su, Z. Shen et al., Effect of scanning speed on the solidification process of Al2O3/GdAlO3/ZrO2 eutectic ceramics in a single track by selective laser melting. Ceram. Int. 45(14), 17252–17257 (2019)

S. Zhai, J. Liu, Q. Liu, Microstructure evolution and toughening mechanism of Al2O3/YSZ directionally solidified eutectic ceramic. J. Alloy. Compd. 873, 159760 (2021)

J. Zhang, H. Su, K. Song et al., Microstructure, growth mechanism and mechanical property of AlO-based eutectic ceramic in situ composites. J. Eur. Ceram. Soc. 31(7), 1191–1198 (2011)

S.Y. Zhai, J.C. Liu, L.F. Nie et al., Microstructure and mechanical properties of Al2O3/MgAl2O4/ZrO2 eutectic ceramic prepared with induction zone melting. Mater Res Innov 19(1), S1-355-S1-358 (2015)

N. Setargew, B.A. Parker, M.J. Couper, Effect of ceramic microspheres on the microstructure of eutectic Al–Si composites. Mater. Sci. Forum (1995). https://doi.org/10.4028/www.scientific.net/MSF.189-190.297

K.A. Jackson, J.D. Hunt, Lamellar and rod eutectic growth. Dyn. Curved Fronts 236(8), 363–376 (1988)

H. Su, J. Zhang, J. Tian et al., Preparation and characterization of Al2O3/Y3Al5O12/ZrO2 ternary hypoeutectic in situ composites by laser rapid solidification. J. Appl. Phys. 104(2), 971 (2008)

Y. Guo, G. Yang, J. Shi et al., Formation of orientation adhesion and dendritic crystal of ZnO nanocrystallites. Integr. Ferroelectr. 147(1), 154–158 (2013)

J.H. Lee, A. Yoshikawa, T. Fukuda et al., Growth and characterization of Al2O3/Y3Al5O12/ZrO2, ternary eutectic fibers. J. Cryst. Growth 231(1–2), 115–120 (2001)

I.S. Medeiros, E.R.M. Andreeta, A.C. Hernandes, Al2O3/GdAlO3 eutectic fibers of high modulus of rupture produced by the laser heated pedestal growth technique. J. Mater. Sci. 42(11), 3874–3877 (2007)

G.K. Bansal, A.H. Heuer, On a martensitic phase transformation in zirconia (ZrO2)—II. Crystallographic aspects. Acta Metall. 22(4), 409–417 (1974)

K. Song, J. Zhang, X. Lin et al., Microstructure and mechanical properties of Al2O3/Y3Al5O12/ZrO2, hypereutectic directionally solidified ceramic prepared by laser floating zone. J. Eur. Ceram. Soc. 34(12), 3051–3059 (2014)

J.D. Hunt, K.A. Jackson, Binary eutectic solidification. Trans. Metal. Soc. AlME 236(6), 843–852 (1966)

Y. Zheng, H. Li, T. Zhou et al., Microstructure and mechanical properties of Al2O3/ZrO2 eutectic ceramic composites prepared by explosion synthesis. J. Alloy. Compd. 551(25), 475–480 (2013)

J. Llorca, J.Y. Pastor, P. Poza et al., Influence of the Y2O3 content and temperature on the mechanical properties of melt-grown Al2O3–ZrO2 eutectics. J. Am. Ceram. Soc. 87(4), 633–639 (2010)

Y. Zhou, Q.L. Ge, T.C. Lei et al., Microstructure and mechanical properties of ZrO2–2 mol% Y2O3, ceramics. Ceram. Int. 16(6), 349–354 (1990)

S. Lakiza, O. Fabrichnaya, C. Wang et al., Phase diagram of the ZrO2–Gd2O3–Al2O3, system. J. Eur. Ceram. Soc. 26(3), 233–246 (2006)

H. Yasuda, I. Ohnaka, Y. Mizutani et al., Three-dimensional observation of the entangled eutectic structure in the Al2O3–YAG system. J. Eur. Ceram. Soc. 25(8), 1397–1403 (2005)

L. Perrière, R. Valle, N. Carrère, Crack propagation and stress distribution in binary and ternary directionally solidified eutectic ceramics. J. Eur. Ceram. Soc. 31(7), 1199–1210 (2011)

Funding

The authors appreciate the support from the National Nature Science Foundation of China [Grant Nos. 51172161 and 52372066].

Author information

Authors and Affiliations

Contributions

RG: conceptualization, experiments, validation, data curation, investigation, writing—original draft. ZC: validation, experiments, data curation, investigation, writing—original draft. SW: validation, data curation, experiments. JL: conceptualization, resources, investigation, supervision, writing—review & editing, project administration. JIPT: supervision, writing—review.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, R., Chu, Z., Wang, S. et al. The evolution of Al2O3/GdAlO3/ZrO2 ternary eutectic ceramic microstructure and property with the growth rate. Journal of Materials Research 39, 801–810 (2024). https://doi.org/10.1557/s43578-023-01270-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-023-01270-9