Abstract

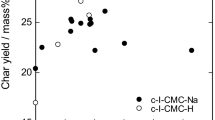

Synthesis of porous carbon materials has been carried out in two ways—by chemical and mechanochemical dehydrochlorination of polyvinyl chloride in the presence of alkali and subsequent two-stage heat treatment of the obtained polyvinylenes (carbonization up to 400°C and carbon dioxide or alkaline activation at a temperature of 850—900 and 800°C, respectively). The products obtained were studied by transmission electron microscopy and low-temperature nitrogen adsorption. It is shown that, depending on the synthesis conditions, carbon materials after activation have a developed specific surface area of 350–1100 m2/g and specific pore volume 0.3–0.47 cm3/g with a variable contribution of micropores from 30 to 85%. Thus, the effectiveness of the chosen approach to the controlled synthesis of porous CMs from PVC is confirmed.

Similar content being viewed by others

REFERENCES

Kryazhev, Yu.G., Solodovnichenko, V.S., Antonicheva, N.V., et al., Prot. Met. Phys. Chem. Surf., 2009, vol. 45, no. 4, p. 398. https://doi.org/10.1134/S2070205109040030

Kryazhev, Yu.G., Solodovnichenko, V.S., Martynenko, E.S., et al., Russ. Chem. Bull., 2015, vol. 64, no. 12, p. 2919. https://doi.org/10.1007/s11172-015-1248-0

Solodovnichenko, V.S., Kryazhev, Yu.G., Arbuzov, A.B., et al., Russ. Chem. Bull., 2016, vol. 65, no. 11, p. 2712. https://doi.org/10.1007/s11172-016-1640-4

Solodovnichenko, V.S., Polyboyarov, V.A., Zhdanok, A.A., et al., Procedia Eng., 2016, vol. 152, p. 747.

Anikeeva, I.V., Kryazhev, Yu.G., Arbuzov, A.B., et al., Russ. J. Appl. Chem., 2018, vol. 91, no. 11, p. 1830. https://doi.org/10.1134/S1070427218110137

Zhang, Q., Saito, F., Shimme, K., and Masuda, S., J. Soc. Powder Technol., Jpn., 1999, vol. 36, p. 468.

Inoue, T., Miyazaki, M., Kamitani, M., et al., Adv. Powder Technol., 2005, vol. 16, no. 1, p. 27.

Inoue, T., Kano, J., and Saito, F., Adv. Powder Technol., 2006, vol. 17, no. 4, p. 425.

Karnaukhov, A.P., Adsorbtsiya. Tekstura dispersnykh i poristykh materialov (Adsorption. Texture of Disperse and Porous Materials), Novosibirsk: Nauka, 1999.

Barrett, E.P., Joiner, L.G., and Halenda, P.H., J. Am. Chem. Soc., 1951, vol. 73, p. 373.

Kryazhev, Yu.G., Anikeeva, I.V., Trenikhin, M.V., et al., Prot. Met. Phys. Chem. Surf., 2020, vol. 56, no. 4, p. 712. https://doi.org/10.31857/S0044185620030237

Beletskaya, M.G. and Bogdanovich, N.I., Russ. J. Bioorg. Chem., 2014, vol. 40, no. 7, p. 717.

Tamarkina, Yu.V., Kucherenko, V.A., and Shendrik, T.G., Solid Fuel Chem., 2014, vol. 48, no. 4, p. 251. https://doi.org/10.7868/S0023117714040112

Kozlov, A.P., Zykov, I.Yu., Dudnikova, Yu.N., et al., Vestn. Kuzbasskogo Gos. Tekh. Univ., 2018, no. 5, p. 68.

Perrin, A., Celzard, A., Albiniak, A., et al., Carbon, 2004, vol. 42, p. 2855.

Wong, S., Ngadi, N., Inuwa, I.M., et al., J. Cleaner Prod., 2018, vol. 175, p. 361.

Spessato, L., Bedin, K.C., Cazetta, A.L., et al., J. Hazard. Mater., 2019, vol. 371, p. 499.

ACKNOWLEDGMENTS

The studies were carried out using the equipment of the National Center for Catalyst Research Center for Collective Use of the Institute of Catalysis and the Omsk Regional Center of Collective Usage SB RAS.

Funding

This work was carried out with the financial support of the Ministry of Science and Higher Education of the Russian Federation within the framework of a state order to the Boreskov Institute of Catalysis, Siberian Branch, Russian Academy of Sciences, project no. AAAA-A21-121011490008-3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kryazhev, Y.G., Anikeeva, I.V., Gulyaeva, T.I. et al. Possibilities of Regulating the Texture Parameters of Porous Carbon Materials Obtained by Alkaline Dehydrochlorination of Polyvinyl Chloride with Subsequent Heat Treatment of Forming Polyvinylenes. Prot Met Phys Chem Surf 57, 806–810 (2021). https://doi.org/10.1134/S2070205121040134

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205121040134