Abstract

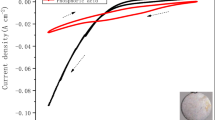

In this work, ruthenium coatings were obtained by the galvanostatic deposition onto a copper substrate. The amount of metallic deposit was increasing with the plating current. The XRD analysis identificated the phase composition and indicated that the change current density can significantly modify the grain orientation of deposits. Plating conditions influence on electrocatalytic performance of ruthenium layers were tested for hydrogen evolution reaction in 1 M NaOH solution. The best catalytic activity were obtained for sample deposited with –60 mA/cm2, what can be connected with good crystallinity and more developed electroactive surface area.

Similar content being viewed by others

REFERENCES

Fernandez, V., Some facts on the platinum-group elements, Int. Rev. Financ. Anal., 2017, vol. 52, p. 333.

Li, Q., Zheng, S., Xu, Y., Xue, H., and Pang, P., Ruthenium based materials as electrode materials for supercapacitors, Chem. Eng. J., 2018, vol. 333, p. 505.

Liu, H., Song, C., and Zhang, L., A review of anode catalysis in the direct methanol fuel cell, J. Power Sources, 2006, vol. 155, p. 95.

Rao, C.R.K. and Trivedi, D.C., Chemical and electrochemical depositions of platinum group metals and their applications, Coord. Chem. Rev., 2005, vol. 249, p. 613.

García-Álvarez, R., Francos, J., Tomás-Mendivil, E., Crochet, P., and Cadierno, V., Metal-catalyzed nitrile hydration reactions: the specific contribution of ruthenium, J. Organomet. Chem., 2014, vol. 771, p. 93.

Chen, Q., Lin, X., and Valvede, C., Electroless copper deposition on ruthenium for damascene interconnects, ECS Trans., 2007, vol. 6, p. 179.

Moffat, T.P., Walker, M., and Chen, P., Electrodeposition of Cu on Ru barrier layers for damascene processing, J. Electrochem. Soc., 2006, vol. 153, p. C37.

Josell, D., Wheeler, D., Witt, C., and Moffat, T., Seedless superfill: copper electrodepositon in trenches with ruthenium barriers, Electrochem. Solid-State Lett., 2003, vol. 6, p. C143.

Parnian, J.M., Khodadadi, A., Najafabadi, A., and Mortazavi, Y., Preferential chemical vapor deposition of ruthenium on cobalt with highly enhanced activity and selectivity for Fischer-Tropsch synthesis, Appl. Catal. A Gen., 2014, vol. 470, p. 221.

Chiba, H., Hirano, M., Kawano, K., Oshima, N., and Funakubo, H., Effect of substrate type and temperature on the growth of thin Ru films by metal organic chemical vapor deposition, Mater. Sci. Semicond. Process., 2017, vol. 70, p. 73.

Chen, J.Y., Huang, S.L., Wu, P.W., and Lin, P., Electroless deposition of Ru films on Si substrates with surface pretreatments, Thin Solid Films, 2013, vol. 529, p. 42612.

Chen, J.Y., Wang, L.Y., and Wu, P.W., Preparation and characterization of ruthenium films via an electroless deposition route, Thin Solid Films, 2010, vol. 518, p. 724513.

Raz, O., Cohn, G., Freyland, W., Mann, O., and Ein-Eli, Y., Ruthenium electrodeposition on silicon from a room-temperature ionic liquid, Electrochim. Acta, 2009, vol. 54, p. 6042.

Jayakumar, M., Venkatesan, K.A., Sudha, R., Srinivasan, T.G., and Vasudeva Rao, P.R., Electrodeposition of ruthenium, rhodium and palladium from nitric acid and ionic liquid media: Recovery and surface morphology of the deposits, Mater. Chem. Phys., 2011, vol. 128, p. 141.

Reddy, G.S. and Taimsalu, P., Electrodeposition of ruthenium, Trans. Inst. Met. Finish., 1969, vol. 47, p. 187.

Kim, Y.S., Kim, H., and Cho, J., Electrochemical deposition of copper and ruthenium on titanium, Electrochim. Acta, 2006, vol. 51, p. 5445.

Chou, Y.S., Yen, S.C., and Jeng, K.T., Fabrication of ruthenium thin film and characterization of its chemical mechanical polishing process, Mater. Chem. Phys., 2015, vol. 162, p. 477.

Philipsen, H. and Monnens, W., Immersion and electrochemical deposition of Ru on Si, Electrochim. Acta, 2018, vol. 274, p. 306.

Oppedisano, D.K., Jones, L.A., Junk, T., and Bhargava, S.K., Ruthenium electrodeposition from aqueous solution at high cathodic overpotential, J. Electrochem. Soc., 2014, vol. 161, p. D489.

Mech, K., Mech, J., Zabinski, P., Kowalik, R., and Wojnicki, M., Electrochemical deposition of alloys in Ru3+–Co2+–Cl−–H2O system, J. Electroanal. Chem., 2015, vol. 748, p.76.

Ding, J., Shao, Q., Feng, Y., and Huang, X., Ruthenium-nickel sandwiched nanoplates for efficient water splitting electrocatalysis, Nano Energy, 2018, vol. 47, p. 1.

ACKNOWLEDGMENTS

The autors would like to express their appreciation to MSc. Piotr Noga (UST-AGH, Faculty of Non-Ferrous Metals) for support with Scanning Electron Microscopy measurements.

Funding

This work was supported by the Polish National Center of Science under grants 2016/21/N/ST8/00222.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Kutyła, D., Kołczyk, K., Żabiński, P. et al. Investigation of Ruthenium Thin Layers Electrodeposition Process under Galvanostatic Conditions from Chloride Solutions. Russ J Electrochem 56, 214–221 (2020). https://doi.org/10.1134/S1023193520030064

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193520030064