Abstract

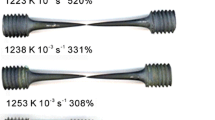

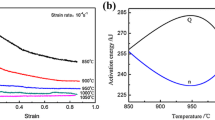

In this paper, the superplastic behavior of SP-700 alloy (Ti–4.5Al–3V–2Mo–2Fe) was investigated by hot compression tests and hot tensile tests in the temperature range of 700–950°C and strain rates of 0.001 to 1 s–1. The microstructural analysis and mechanical behavior of the alloy were studied during superplastic deformation. Although the elongation became higher than 370% at 700°C, the alloy showed a relatively high work hardening. At 750 and 800°C, the typical superplasticity was occurred and the specimens endured a large elongation of 427–440%. Microstructure of the alloy in 700–800°C was mainly consisted of globular α phase, while the globular α phase was completely removed in the tip fracture of the specimen deformed at 850°C due to deformation-induced transformation. In the temperature range of 850–950°C, the elongation was decreased to 250–325% as a consequence of the removal of α phase, significant β grain growth, and crack formation along β/β grain boundaries. The maximum elongation of 440% was obtained at 800°C where the strain-rate sensitivity is equal to 0.38 which is accommodated by the m-value distribution map of the alloy. During superplastic deformation in the single β phase region, the Rachinger grain boundary sliding (GBS) mechanism is the dominant phenomenon. However, deformation in the dual-phase α/β region is encouraged by dynamic recrystallization (DRX) and decomposition of α colonies.

Similar content being viewed by others

REFERENCES

M. J. Tan and S. F. Hassan, “High temperature deformation of Ti SP-700,” in Ti-2007 Science and Technology (2007), pp. 567–570.

E. Alabort, P. Kontis, D. Barba, K. Dragnevski, and R. C. Reed, “On the mechanisms of superplasticity in Ti–6Al–4V,” Acta Mater. 105, 449–463 (2016). https://doi.org/10.1016/j.actamat.2015.12.003

M. L. Meier, D. R. Lesuer, and A. K. Mukherjee, “α Grain size and β volume fraction aspects of the superplasticity of Ti-6Al-4V,” Mater. Sci. Eng., A 136, 71–78 (1991). https://doi.org/10.1016/0921-5093(91)90442-p

J. Shen, Yu. Sun, Yo. Ning, H. Yu, Z. Yao, and L. Hu, “Superplasticity induced by the competitive DRX between BCC beta and HCP alpha in Ti–4Al–3V–2Mo–2Fe alloy,” Mater. Charact. 153, 304–317 (2019). https://doi.org/10.1016/j.matchar.2019.05.014

R. Boyer, G. Welsch, and E. W. Collings, Materials Property Handbook: Ti Alloys (ASM International, 1994).

Yi-H. Lin, Sh.-M. Wu, F.-H. Kao, Sh.-H. Wang, J.‑R. Yang, Ch.-Ch. Yang, and Ch.-Sh. Chiou, “Microtwin formation in the α phase of duplex titanium alloys affected by strain rate,” Mater. Sci. Eng., A 528, 2271–2276 (2011). https://doi.org/10.1016/j.msea.2010.12.027

H. Fukai, A. Ogawa, K. Minakawa, H. Sato, and T. Tsuzuku, “Hot forming characteristics of SP-700 alloy,” in Ti-2003 Science and Technology (2003), pp. 635–642.

E. Alabort, D. Barba, and R. Reed, “Mechanisms of superplasticity in titanium alloys: Measurement, in situ observations and rationalization,” Defect Diffus. Forum 385, 65–71 (2018). https://doi.org/10.4028/www.scientific.net/ddf.385.65

S. Biswas, B. Beausir, L. S. Toth, and S. Suwas, “Evolution of texture and microstructure during hot torsion of a magnesium alloy,” Acta Mater. 61, 5263–5277 (2013). https://doi.org/10.1016/j.actamat.2013.05.018

Y. Q. Ning, X. Luo, H. Q. Liang, H. Z. Guo, J. L. Zhang, and K. Tan, “Competition between dynamic recovery and recrystallization during hot deformation for TC18 titanium alloy,” Mater. Sci. Eng., A 635, 77–85 (2015). https://doi.org/10.1016/j.msea.2015.03.071

P. J. Bania, “Beta titanium alloys and their role in the titanium industry,” JOM 46 (7), 16–19 (1994). https://doi.org/10.1007/bf03220742

J. J. Jonas, C. Aranas, A. Fall, and M. Jahazi, “Transformation softening in three titanium alloys,” Mater. Des. 113, 305–310 (2017). https://doi.org/10.1016/j.matdes.2016.10.039

R. D. K. Misra, J. Hu, I. V. S. Yashwanth, V. S. A. Challa, L.-X. Du, G.-S. Sun, and H. Xie, “Phase reverted transformation-induced nanograined microalloyed steel: Low temperature superplasticity and fracture,” Mater. Sci. Eng., A 668, 105–111 (2016). https://doi.org/10.1016/j.msea.2016.05.052

L. Huang, P. Hua, W. Sun, F. Liu, and F. Qi, “Necking characteristics and dynamic recrystallization during the superplasticity of IN718 superalloy,” Mater. Sci. Eng., A 647, 277–286 (2015). https://doi.org/10.1016/j.msea.2015.09.040

A. H. Sheikhali, M. Morakkabati, and S. M. Abbasi, “Constitutive modeling for hot working behavior of SP‑700 titanium alloy,” J. Mater. Eng. Perform. 28, 6525–6537 (2019). https://doi.org/10.1007/s11665-019-04355-x

J. Koike, Y. Shimoyama, I. Ohnuma, T. Okamura, R. Kainuma, K. Ishida, and K. Maruyama, “Stress-induced phase transformation during superplastic deformation in two-phase Ti–Al–Fe alloy,” Acta Mater. 48, 2059–2069 (2000). https://doi.org/10.1016/s1359-6454(00)00049-5

G. E. Dieter, H. A. Kuhn, and S. L. Semiatin, Handbook of Workability and Process Design (ASM International, 2003).

A. Ogawa, M. Niikura, C. Ouchi, K. Minikawa, and M. Yamada, “Development and applications of titanium alloy SP-700 with high formability,” J. Test. Eval. 24, 100–109 (1996). https://doi.org/10.1520/JTE12683J

A. Wisbey, B. Geary, D. P. Davies, and C. M. Ward-Close, “Superplastic deformation and diffusion bonding of the low deformation temperature titanium alloy SP700,” Mater. Sci. Forum 170–172, 293–298 (1994). https://doi.org/10.4028/www.scientific.net/msf.170-172.293

B. Gershon and I. Eldror, “Superplastic sheet forming of aircraft parts from Ti-alloys,” in Ti-2007 Science and Technology (2007), pp. 1287–1290.

A. H. Sheikhali, M. Morakkabati, and S. M. Abbasi, “Hot torsion behavior of SP-700 near beta titanium alloy in single and dual phase regions,” Int. J. Mater. Res. 109, 1136–1145 (2018). https://doi.org/10.3139/146.111715

A. H. Sheikhali and M. Morakabati, “Hot working of SP-700 with lamellar structure using a processing map,” Int. J. Mater. Res. 111, 297–306 (2020).

AMS 4964C, Ti Alloy Bars, Wire, Forgings, and Rings Ti–4.5Al–3V–2Fe–2Mo Annealed (2011).

Z. Guo, S. Malinov, and W. Sha, “Modelling beta transus temperature of titanium alloys using artificial neural network,” Comput. Mater. Sci. 32, 1–12 (2005). https://doi.org/10.1016/j.commatsci.2004.05.004

P. M. Souza, H. Beladi, R. Singh, B. Rolfe, and P. D. Hodgson, “Constitutive analysis of hot deformation behavior of a Ti6Al4V alloy using physical based model,” Mater. Sci. Eng., A 648, 265–273 (2015). https://doi.org/10.1016/j.msea.2015.09.055

ASTM E209-00, Standard Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates and Strain Rates (ASTM International, 2010).

ASTM E3-11, Standard Guide for Specimens (ASTM International, West Conshohocken, Pa., 2011).

I. Balasundar, T. Raghu, and B. P. Kashyap, “Modeling the hot working behavior of near-α titanium alloy IMI 834,” Prog. Nat. Sci.: Mater. Int. 23, 598–607 (2013). https://doi.org/10.1016/j.pnsc.2013.11.004

K. A. Padmanabhan, R. A. Vasin, and F. U. Enikeev, Superplastic Flow: Phenomenology and Mechanics, Engineering Materials (Springer, Berlin, 2001). https://doi.org/10.1007/978-3-662-04367-7

H. Q. Liang, Y. Nan, Y. Q. Ning, H. Li, J. L. Zhang, Z. F. Shi, and H. Z. Guo, “Correlation between strain-rate sensitivity and dynamic softening behavior during hot processing,” J. Alloys Compd. 632, 478–485 (2015). https://doi.org/10.1016/j.jallcom.2014.12.270

O. Sivakesavam and Y. V. R. K. Prasad, “Characteristics of superplasticity domain in the processing map for hot working of as-cast Mg–11.5Li–1.5Al alloy,” Mater. Sci. Eng., A 323, 270–277 (2002). https://doi.org/10.1016/s0921-5093(01)01392-2

V. G. Krishna, Y. V. R. K. Prasad, N. C. Birla, and G. Rao, “Processing map for the hot working of near-α titanium alloy 685,” J. Mater. Process. Technol. 71, 377–383 (1997). https://doi.org/10.1016/s0924-0136(97)00102-7

P. Wanjara, M. Jahazi, H. Monajati, S. Yue, and J.‑P. Immarigeon, “Hot working behavior of near-α alloy IMI834,” Mater. Sci. Eng., A 396, 50–60 (2005). https://doi.org/10.1016/j.msea.2004.12.005

I. Philippart and H. J. Rack, “High temperature dynamic yielding in metastable Ti–6.8Mo–4.5F–1.5Al,” Mater. Sci. Eng., A 243, 196–200 (1998). https://doi.org/10.1016/s0921-5093(97)00800-9

A. H. Sheikhali, M. Morakkabati, S. M. Abbasi, and A. Rezaei, “Superplasticity of coarse-grained Ti–13V–11Cr–3Al alloy,” Int. J. Mater. Res. 104, 1122–1127 (2013). https://doi.org/10.3139/146.110965

Q. J. Sun, G. C. Wang, and M. Q. Li, “The superplasticity and microstructure evolution of TC11 titanium alloy,” Mater. Des. 32, 3893–3899 (2011). https://doi.org/10.1016/j.matdes.2011.02.062

J. S. Kim, J. H. Kim, Y. T. Lee, C. G. Park, and C. S. Lee, “Microstructural analysis on boundary sliding and its accommodation mode during superplastic deformation of Ti–6Al–4V alloy,” Mater. Sci. Eng., A 263, 272–280 (1999). https://doi.org/10.1016/s0921-5093(98)01157-5

H. Z. Niu, F. T. Kong, Y. Y. Chen, and C. J. Zhang, “Low-temperature superplasticity of forged Ti–43Al–4Nb–2Mo–0.5B alloy,” J. Alloys Compd. 543, 19–25 (2012). https://doi.org/10.1016/j.jallcom.2012.07.127

L. He, A. Dehghan-Manshadi, and R. J. Dippenaar, “The evolution of microstructure of Ti–6Al–4V alloy during concurrent hot deformation and phase transformation,” Mater. Sci. Eng., A 549, 163–167 (2012). https://doi.org/10.1016/j.msea.2012.04.025

A. Dehghan-Manshadi and R. J. Dippenaar, “Strain-induced phase transformation during thermo-mechanical processing of titanium alloys,” Mater. Sci. Eng., A 552, 451–456 (2012). https://doi.org/10.1016/j.msea.2012.05.069

J. Pilling and N. Ridley, Superplasticity in Crystalline Solids (The Inst. of Met. Publ., London, 1989).

A. K. Mukherjee, J. E. Bird, and J. E. Dorn, “Experimental correlations for high-temperature creep,” Trans. Am. Soc. Met. 62, 155–164 (1969).

Z. Ma and R. S. Mishra, “Superplastic deformation mechanism,” in Friction Stir Superplasticity for Unitized Structures (Butterworth-Heinemann, New York, 2014), pp. 39–57. https://doi.org/10.1016/B978-0-12-420006-7.00006-6

W. A. Rachinger, “Relative grain translations in the plastic flow of Al,” J. Inst. Met. 81 (1952).

I. M. Lifshitz, “On the theory of diffusion-viscous flow of polycrystalline bodies,” Sov. Phys. 17, 909–920 (1963).

Funding

This work was supported by ongoing institutional funding. No additional grants to carry out or direct this particular research were obtained.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Morakabati, M., Sheikhali, A.H. Microstructural Evolution and Mechanical Behavior of SP-700Ti Alloy during Superplastic Deformation. Phys. Metals Metallogr. 124, 1579–1587 (2023). https://doi.org/10.1134/S0031918X2260213X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X2260213X