Abstract

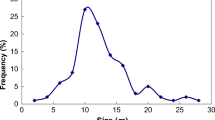

The microstructure of particle-reinforced metal matrix composites (PMMCs) and its parameters (such as particle size distribution, particle volume fraction, particle shape, etc.) have a great influence on the elastic modulus of PMMC. In this paper, the intermingled fractal units (IFU) model was used to describe the microstructure of PMMCs. Based on the spring series-parallel connection model, an analytical method of predicting the elastic modulus was proposed, and the area fraction, size distribution, and interface of the reinforced particles were taken into consideration. The tensile experiments performed on three groups of the SiC/Al composite specimens with different microstructure (namely, of different particle shape, size, and volume fraction of reinforcing particles) were conducted to evaluate the elastic modulus and strength properties. The comparison between the predicted and experimental results has proved the applicability and effectiveness of the method proposed in this paper.

Similar content being viewed by others

REFERENCES

A. Melaibari, A. Fathy, M. Mansouri, and M. A. Eltaher, “Experimental and numerical investigation on strengthening mechanisms of nanostructured Al–SiC composites,” J. Alloy Compd. 774, 1123–1132 (2019).

X. Gao, X. Zhang, and L. Geng, “Strengthening and fracture behaviors in SiCp/Al composites with network particle distribution architecture,” Mater. Sci. Eng., A 740–741, 353–362 (2019).

C. Wu, J. Zhang, G. Luo, Q. Shen, Z. Gan, J. Liu, and L. Zhang, “Interfacial segregation and precipitates behavior in the ultrafine grained Al-based metal matrix composites,” J. Alloy Compd. 770, 625–630 (2019).

J. B. Ferguson, X. Thao, P. K. Rohatgi, K. Cho, and C.-S. Kim, “Computational and analytical prediction of the elastic modulus and yield stress in particulate-reinforced metal matrix composites,” Scr. Mater. 83, 45–48 (2014).

N. Chawla, U. Habel, Y.-L. Shen, C. Andres, J. W. Jones, and J. E. Allison, “The effect of matrix microstructure on the tensile and fatigue behavior of SiC particle-reinforced 2080 Al matrix composites,” Metall. Mater. Trans. A 31, 531–540 (2000).

M. Song, “Effects of volume fraction of SiC particles on mechanical properties of SiC/Al composites,” Trans. Nonferrous Met. Soc. China 19, 1400–1404 (2009).

L. C. Bian, W. Liu, and J. Pan, “Probability of debonding and effective elastic properties of particle-reinforced composites,” J. Mech. 33, 789–796 (2017).

C. Sun, M. Song, Z. Wang, and Y. He, “Effect of particle size on the microstructures and mechanical properties of SiC-reinforced pure aluminum composites,” J. Mater. Eng. Perform. 20, 1606–1612 (2011).

S. G. Song, N. Shi, G. T. Gray III, and J. A. Roberts, “Reinforcement shape effects on the fracture behavior and ductility of particulate-reinforced 6061-Al matrix composites,” Metall. Mater. Trans. A 27, 3739–3746 (1996).

Y. Tang, Z. Chen, A. Borbély, G. Ji, S. Y. Zhong, D. Schryvers, et al., “Quantitative study of particle size distribution in an in-situ grown Al–TiB2 composite by synchrotron X-ray diffraction and electron microscopy,” Mater. Charact. 102, 131–136 (2015).

W. Voigt, “Ueber die Beziehung zwischen den beiden Elasticitätsconstanten isotroper Körper,” Ann. Phys. (Berlin) 274, 573–587 (1889).

A. Reuss, “A calculation of the bulk modulus of polycrystalline materials,” Math. Methods 9, 49–58 (1929).

R. Hill, “A self-consistent mechanics of composite materials,” J. Mech. Phys. Solids 13, 213–222 (1965).

T. Mori and K. Tanaka, “Average stress in matrix and average elastic energy of materials with misfitting inclusions,” Acta Metall. 21, 571–574 (1973).

M. Song and D. Xiao, “Modeling the fracture toughness and tensile ductility of SiCp/Al metal matrix composites,” Mater. Sci. Eng., A 474, 371–375 (2008).

D. J. Eshelby, “The determination of the elastic field of an ellipsoidal inclusion, and related problems,” Proc. R. Soc. London, Ser. A 241, 376–396 (1957).

J. F. Zhang, X. X. Zhang, Q. Z. Wang, B. L. Xiao, and Z. Y. Ma, “Simulation of anisotropic load transfer and stress distribution in SiCp/Al composites subjected to tensile loading,” Mech. Mater. 122, 96–103 (2018).

H. Qing, “Micromechanical study of influence of interface strength on mechanical properties of metal matrix composites under uniaxial and biaxial tensile loadings,” Comput. Mater. Sci. 89, 102–113 (2014).

L. Molent, A. Spagnoli, A. Carpinteri, and R. Jones, “Using the lead crack concept and fractal geometry for fatigue lifting of metallic structural components,” Int. J. Fatigue 102, 214–220 (2017).

W. Wei, J. Cai, X. Hu, P. Fan, Q. Han, J. Lu, et al., “A numerical study on fractal dimensions of current streamlines in two-dimensional and three-dimensional pore fractal models of porous media,” Fractals 23, 1540012 (2015).

B. B. Mandelbrot, The Fractal Geometry of Nature (W.H. Freeman, New York, 1983).

V. Hotař and A. Hotař, “Fractal dimension used for evaluation of oxidation behavior of Fe–Al–Cr–Zr–C alloys,” Corros. Sci. 133, 141–149 (2018).

A. Zhou, Y. Fan, W.-C. Cheng, and J. Zhang, “A fractal model to interpret porosity-dependent hydraulic properties for unsaturated soils,” Adv. Civil Eng. 2019, 1–13 (2019).

J. Liu, W. Huo, X. Zhang, B. Ren, Y. Li, Z. Zhang, and J. Yang, “Optimal design on the high-temperature mechanical properties of porous alumina ceramics based on fractal dimension analysis,” J. Adv. Ceram. 7, 89–98 (2018).

C. Atzeni, G. Pia, and U. Sanna, “Fractal modeling of medium–high porosity SiC ceramics,” J. Eur. Ceram. Soc. 28, 2809–2814 (2008).

C. Zhang, Y. Chen, and W. Yao, “The use of fractal dimensions in the prediction of residual fatigue life of pre-corroded aluminum alloy specimens,” Int. J. Fatigue 59, 282–291 (2014).

G. Pia and U. Sanna, “Intermingled fractal units model and electrical equivalence fractal approach for prediction of thermal conductivity of porous materials,” Appl. Therm. Eng. 61, 186–192 (2013).

G. Pia and U. Sanna, “An intermingled fractal units model and method to predict permeability in porous rock,” Int. J. Eng. Sci. 75, 31–39 (2014).

G. Pia, L. Casnedi, M. Ionta, and U. Sanna, “On the elastic deformation properties of porous ceramic materials obtained by pore-forming agent method,” Ceram. Int. 41, 11097–11105 (2015).

Z.-L. Chen, N.-T. Wang, L. Sun, X.-H. Tan, and S. Deng, “Prediction method for permeability of porous media with tortuosity effect based on an intermingled fractal units model,” Int. J. Eng. Sci. 121, 83–90 (2017).

W. Liu and L. Bian, “Influences of inclusions and corresponding interphase on elastic properties of composites,” Arch. Appl. Mech. 88, 1507–1524 (2018).

Funding

This study was funded by the National Science and Technology Major Project (2017-VI-0003-0073) and the Priority Academic Program Development of Jiangsu Higher Education Institutions (grant no. 1108007002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Wen Jiang, Yao, W., Li, P. et al. On the Effective Elastic Properties of SiC/Al Metal Matrix Composite within an Intermingled Fractal Units Model. Phys. Metals Metallogr. 122, 1409–1418 (2021). https://doi.org/10.1134/S0031918X21130056

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21130056